Lamp for vehicle

A technology for lamps and vehicles, applied in vehicle parts, lighting and heating equipment, fixed lighting devices, etc., can solve the problems of increasing the energy consumption of the whole lamp, heavy weight, etc. blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

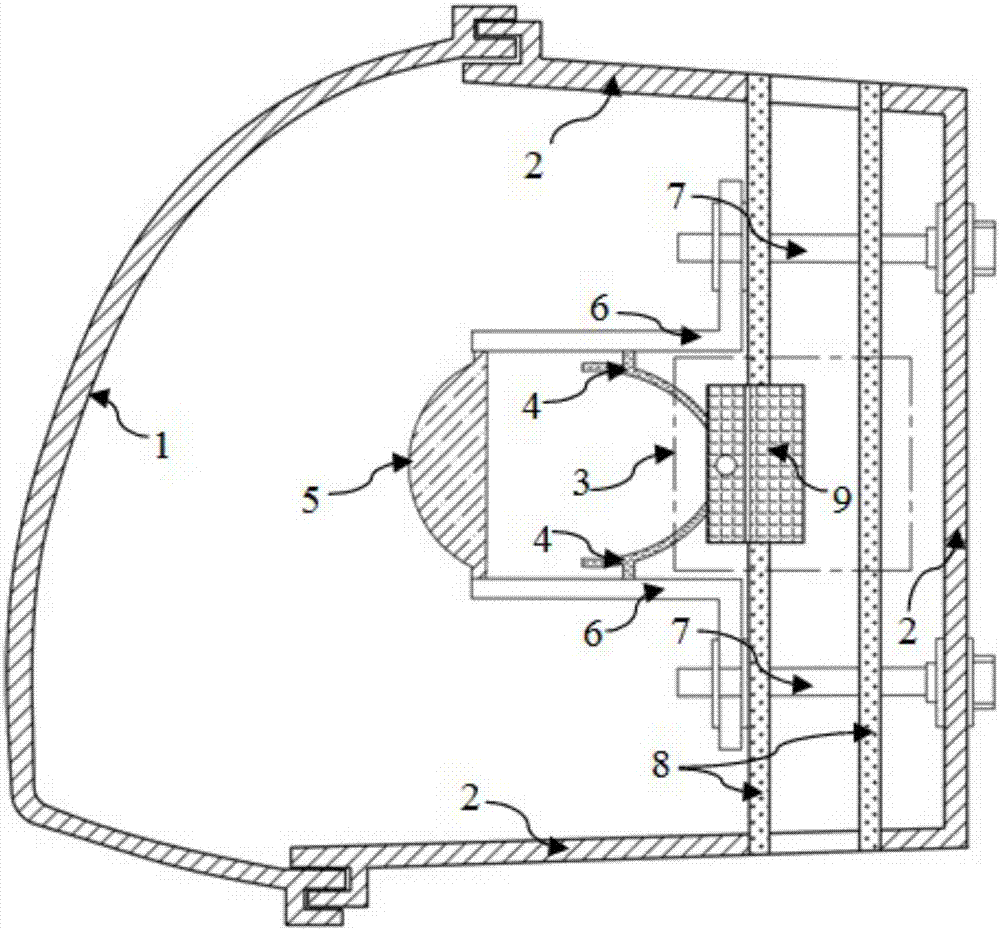

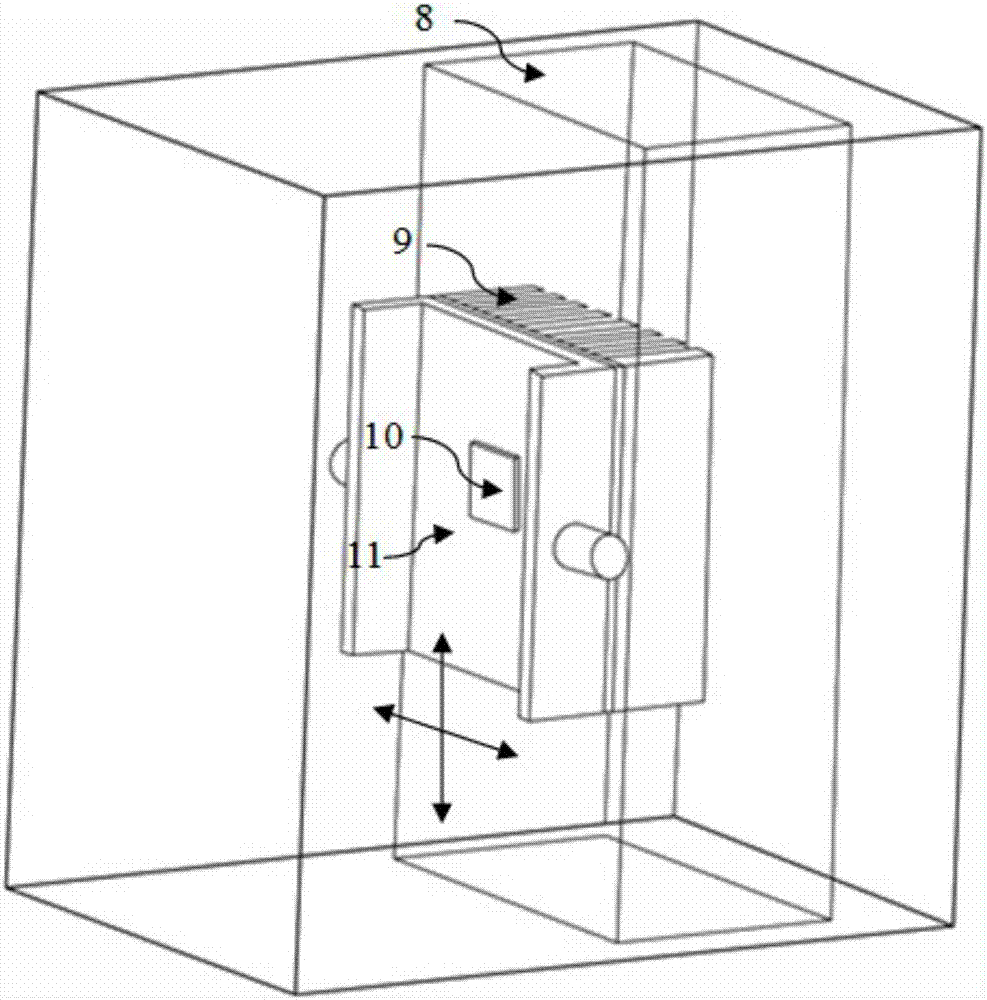

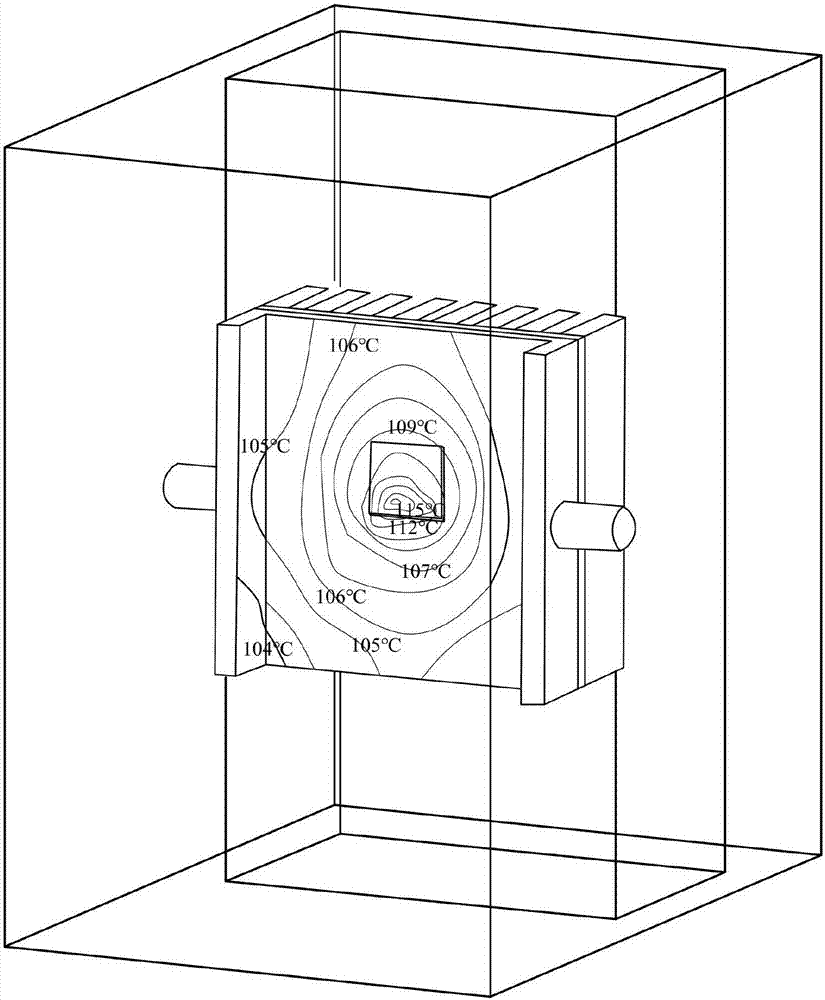

[0026] The invention discloses a vehicle lamp, such as figure 1 , 2 , 3 and 4, including a lamp body 2, an elastomer pipe 8, a radiator 9 and a light source, the upper side wall and the lower side wall of the lamp body are provided with an opening structure for connecting the elastomer pipe, That is, the elastomer pipe runs through the lamp body up and down through the opening structure and is fixedly connected with the lamp body. Both ends of the elastomer pipe are open and communicated with the atmosphere. The radiator is installed on the On the wall of the elastomer pipe, the fin part of the radiator extends into the elastomer pipe and is in direct contact with the air flowing in the pipe, the other parts of the radiator are located outside the elastomer pipe, the The inner side of the lamp body is used as the basic structure for the fixed installation of the light source. The heat generated during the light emitting process of the light source is first transferred to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com