Mounting rod

A technology of mounting rod and mounting structure, applied in the field of mounting rod, can solve the problems of inability to install accessories, incoherent overall shape, strong local pressure, etc., to achieve the effect of improving flexibility, neat and coherent appearance, and clean appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

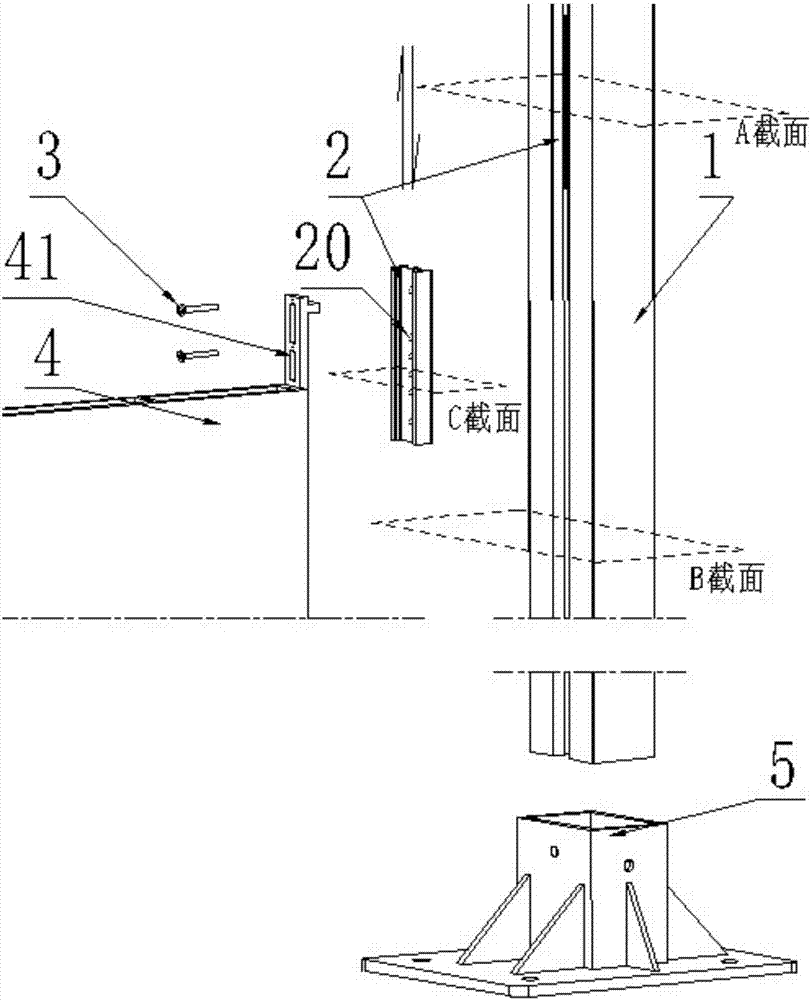

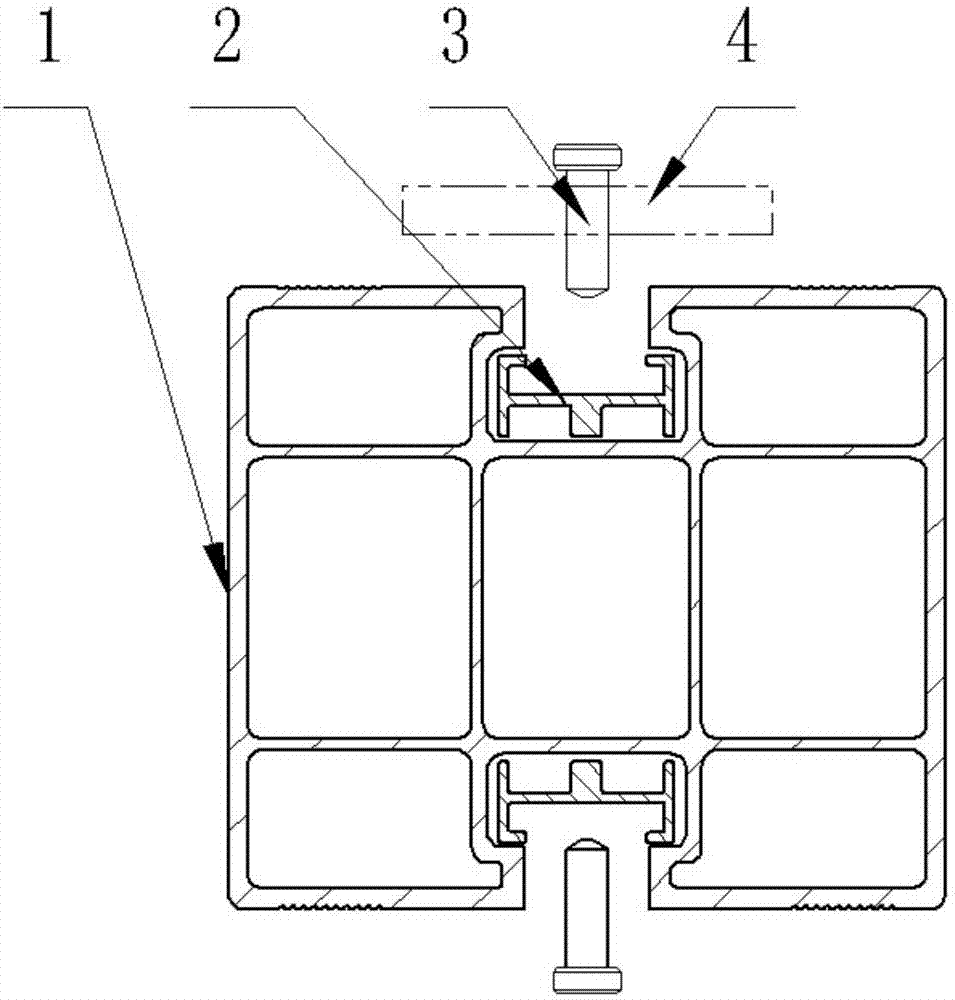

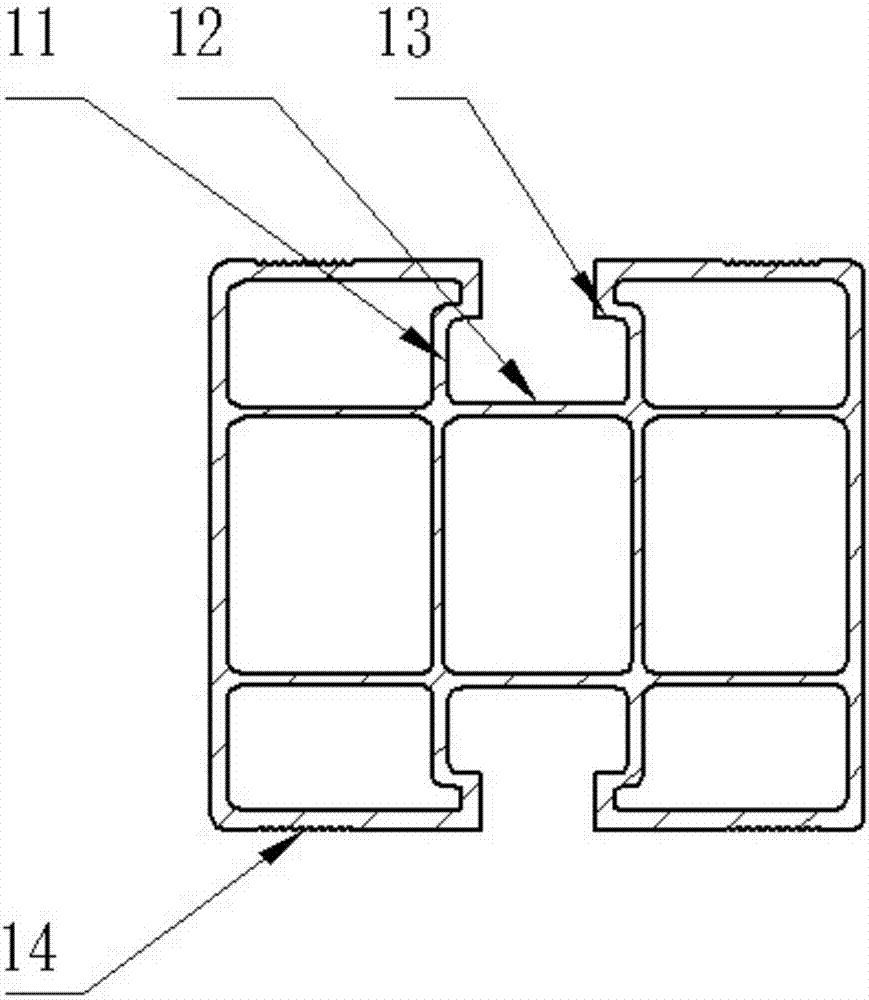

[0046] Such as image 3 The cross-section of an aluminum profile rod body is shown, which provides a cross-sectional structure with grooves, light weight and high strength. The rod body is an integrally formed aluminum profile 1 extending along the cross section.

[0047] The section of the aluminum profile 1 is in the shape of a "nine-square grid", which includes 1 heart grid, 4 corner grids and 4 side grids. Such as image 3 As shown, two opposite side panels form grooves by means of openings. In this way, the structural wall is used to directly form the groove, which saves materials and helps reduce the overall weight.

[0048] The outer wall shown in the figure is a rectangle, but it can actually be designed as a polygon or even a bow. Any of these shapes will work. However, the groove is preferably arranged on a plane, and the body of the groove extends along the entire length of the installation rod.

[0049] image 3Among them, the outer wall is preferably thicke...

Embodiment 2

[0056] Such as image 3 In the cross-section of a rod body of an aluminum profile shown, the outer wall of the aluminum profile where the notch is located is connected and closed. The rod body is an integrally formed aluminum profile 1 extending along the cross section of the closed state.

[0057] At the position where the groove is to be arranged, use machining or electric machining to cut the outer wall along the length direction, so that a section of the mounting rod is formed as image 3 groove shown. The slide block 2 can be put in from one end of the mounting rod and slide to the groove. Specifically, if the slider interferes with the closed notch, then the groove needs to extend to one end of the mounting rod. The slider 2 corresponding to the groove needs to be put in from the one end of the mounting rod.

[0058] Adapter

[0059] The adapter comprises a slider 2 and at least one bolt 3 . The slider 2 is used to fix the accessory 4 on the mounting rod by means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com