Valve spool displacement measuring test bed

A valve core displacement and test bench technology, which is applied in measuring devices, radio wave measurement systems, electromagnetic wave re-radiation and other directions, can solve the problem that high-speed switching valves cannot measure valve core displacement, etc., to improve market competitiveness, simple structure, Production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

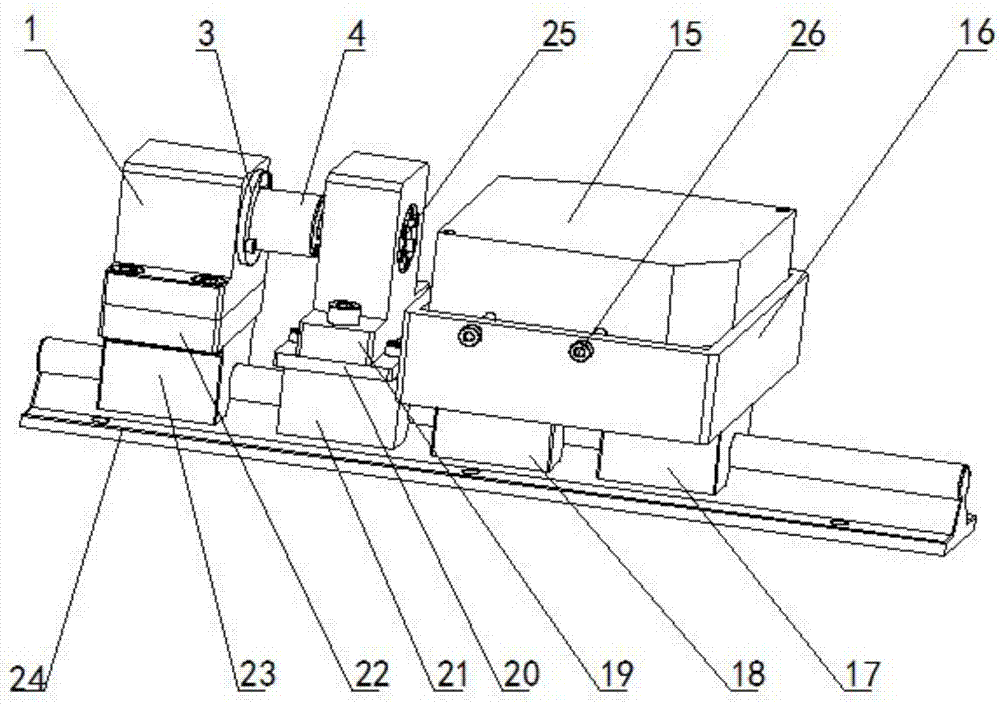

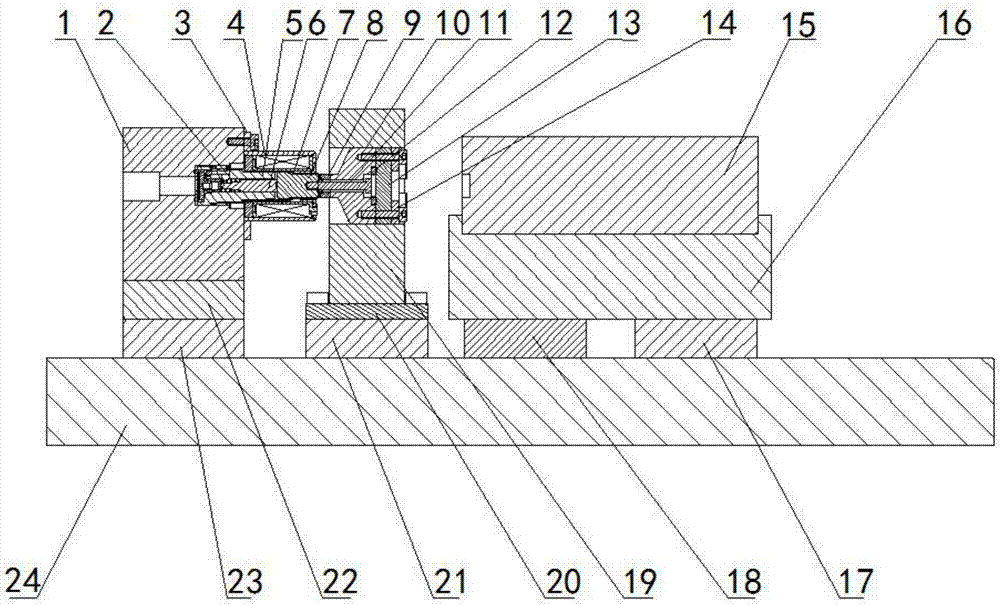

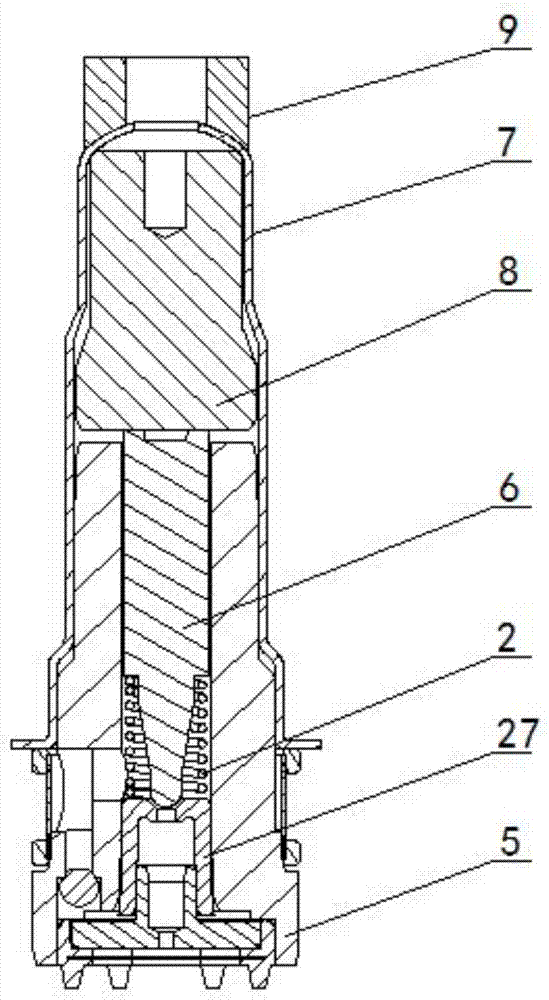

[0037] Such as Figure 1-4 As shown, the valve core displacement measurement test bench provided in this embodiment includes a linear guide rail 24, a valve seat 1, a first sliding part 21, a second sliding part 23, a third sliding part, a flange 3, an electromagnet coil 4, Sealing chamber 25, support 19, transition ring 9, laser displacement sensor 15 and mounting seat 16;

[0038] Such as Figure 1-2 As shown, the first sliding part 21, the second sliding part 23 and the third sliding part are sequentially slidably connected with the linear guide rail 24, the valve seat 1 is mounted on the first sliding part 21, and the valve The seat 1 is provided with an installation cavity, the first end of the switch valve is arranged in the installation cavity, the second end of the switch valve is provided with a through hole, and the moving iron 8 of the switch valve is provided with a connection hole , and the electromagnet coil 4 is fixed on the valve seat 1 through the flange 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com