Watertight connector for underwater towed sonar

A watertight connector and sonar technology, applied in the direction of testing/measuring connectors, connections, connecting device components, etc., can solve the problems of cable fiber optic cable damage, cable design protection, large size specifications, etc. Light, seawater corrosion resistance, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

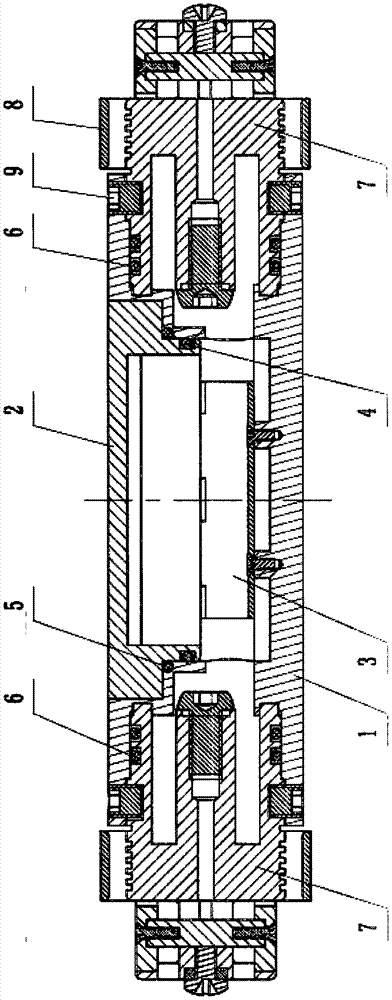

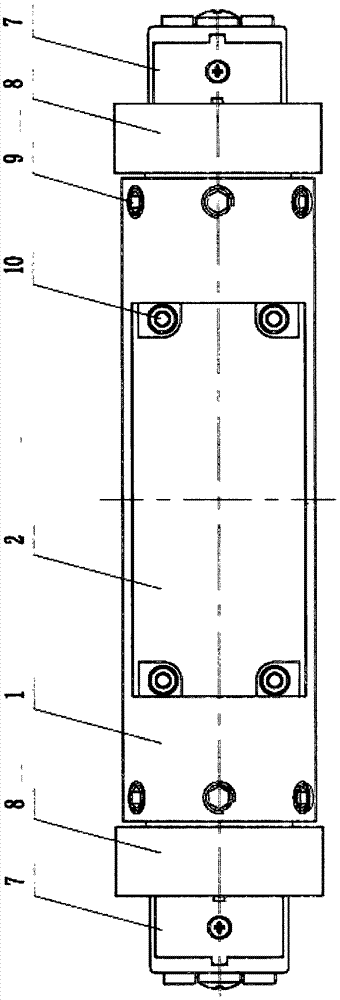

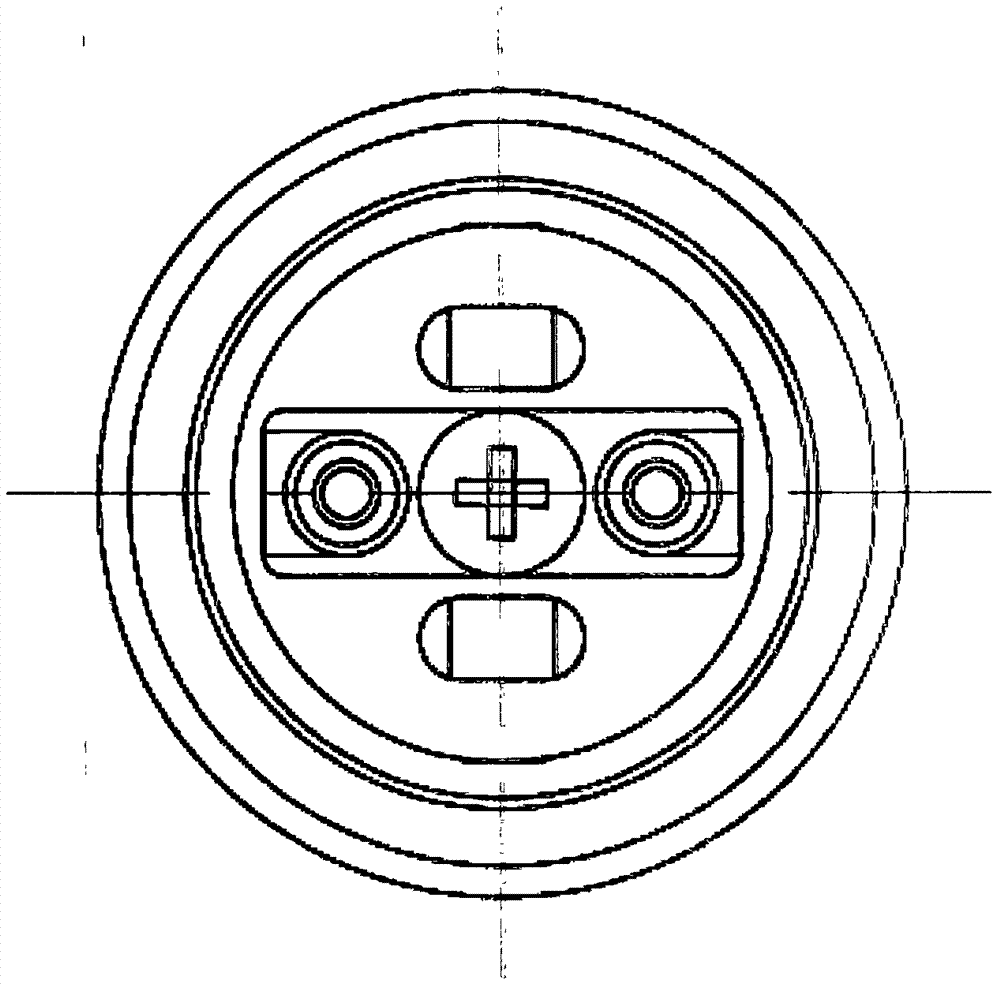

[0024] Such as Figure 1 to 3 As shown, the connector includes a watertight connector box 1, a watertight connector cover 2, a storage protection box 3, an O-ring a 4, an O-ring b 5, an O-ring c 6, a plug 7, a plug Head crimping ring 8, Kimi screw 9, and hexagon socket screw 10. Among them, the storage protection box 3 is made of a flexible material, such as soft plastic or silica gel. O-shaped sealing ring a 4, O-shaped sealing ring b 5, O-shaped sealing ring c 6 are made of fluorine rubber, which has good resistance to seawater corrosion and aging. Other structural parts are made of light-weight, high-strength, seawater corrosion-resistant material aluminum alloy or titanium alloy.

[0025] Specific, such as figure 1 As shown, the watertight connector box 1, the watertight connector cover 2, the O-ring a 4, the O-ring b 5, the O-ring c 6 and the plug 7 form a closed space. The contact and installation parts of the enclosed space are all sealed with two layers of O-rings, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com