Method for improving stability of blueberry anthocyanin through attapulgite

A blueberry anthocyanin, stability technology, applied in the direction of application, pharmaceutical formula, organic active ingredients, etc., can solve the limitation of the application range of blueberry anthocyanin, the difficulty of chemically synthesizing blueberry anthocyanin, and affecting the stability of blueberry anthocyanin and other issues, to achieve low cost, low operating environment requirements, and improve the effect of antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

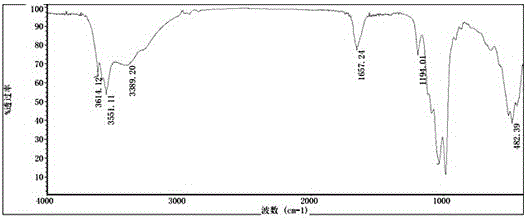

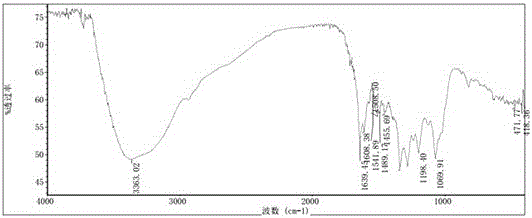

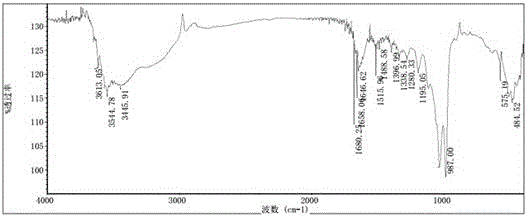

Image

Examples

Embodiment 1

[0026] A: Pulverize the attapulgite, pass it through a 200-mesh sieve, soak it with water, squeeze it against the roller three times, add deionized water to make a slurry, beat at 10,000 rpm for 30 minutes to disperse the attapulgite, and centrifuge at 1,500 rpm for 15 minutes. Take the upper layer suspension, continue to centrifuge the upper layer suspension at 3000 rpm for 30 min to obtain a paste, put it into an electric blast drying oven and dry it into a powder for later use.

[0027] B: Mix 0.5g of the attapulgite obtained in step A (with a particle size of 70µm) and 1g of blueberry anthocyanin evenly, add 0.6ml of ultrapure water and grind until the water is completely evaporated (about 15 minutes) to obtain blueberry anthocyanin Plain-attapulgite mixture.

Embodiment 2

[0029] A: Pulverize the attapulgite, pass it through a 200-mesh sieve, soak it with water, squeeze it against the roller three times, add deionized water to make a slurry, beat at 10,000 rpm for 30 minutes to disperse the attapulgite, and centrifuge at 1,500 rpm for 15 minutes. Take the upper layer suspension, continue to centrifuge the upper layer suspension at 3000 rpm for 30 min to obtain a paste, put it into an electric blast drying oven and dry it into a powder for later use.

[0030] B: Mix 1g of the attapulgite obtained in step A (with a particle size of 70µm) and 1g of blueberry anthocyanin evenly, add 0.8ml of ultrapure water and grind until the water is completely evaporated (about 15 minutes) to obtain blueberry anthocyanin - Attapulgite mix.

Embodiment 3

[0032] A: Pulverize the attapulgite, pass it through a 200-mesh sieve, soak it with water, squeeze it against the roller three times, add deionized water to make a slurry, beat at 10,000 rpm for 30 minutes to disperse the attapulgite, and centrifuge at 1,500 rpm for 15 minutes. Take the upper layer suspension, continue to centrifuge the upper layer suspension at 3000 rpm for 30 min to obtain a paste, put it into an electric blast drying oven and dry it into a powder for later use.

[0033] B: Take 2g of the attapulgite obtained in step A (particle size is 70µm) and mix evenly with 1g of blueberry anthocyanin, add 1.2ml of ultra-pure water and grind until the water is completely evaporated (about 15 minutes) to obtain blueberry anthocyanin - Attapulgite mix.

[0034] performance measurement

[0035] (1) Comparison of the stability of blueberry anthocyanin-attapulgite mixture and blueberry anthocyanin in acidic solution

[0036] Take 5.1 g of sodium acetate, mix with 20 mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com