A Multi-bed Axial Radial Reactor

An axial-radial, reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of obvious amplification effect, high production capacity, small pressure drop in the bed, etc., to avoid gas bias flow and ensure stable The effect of running, avoiding the reaction dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

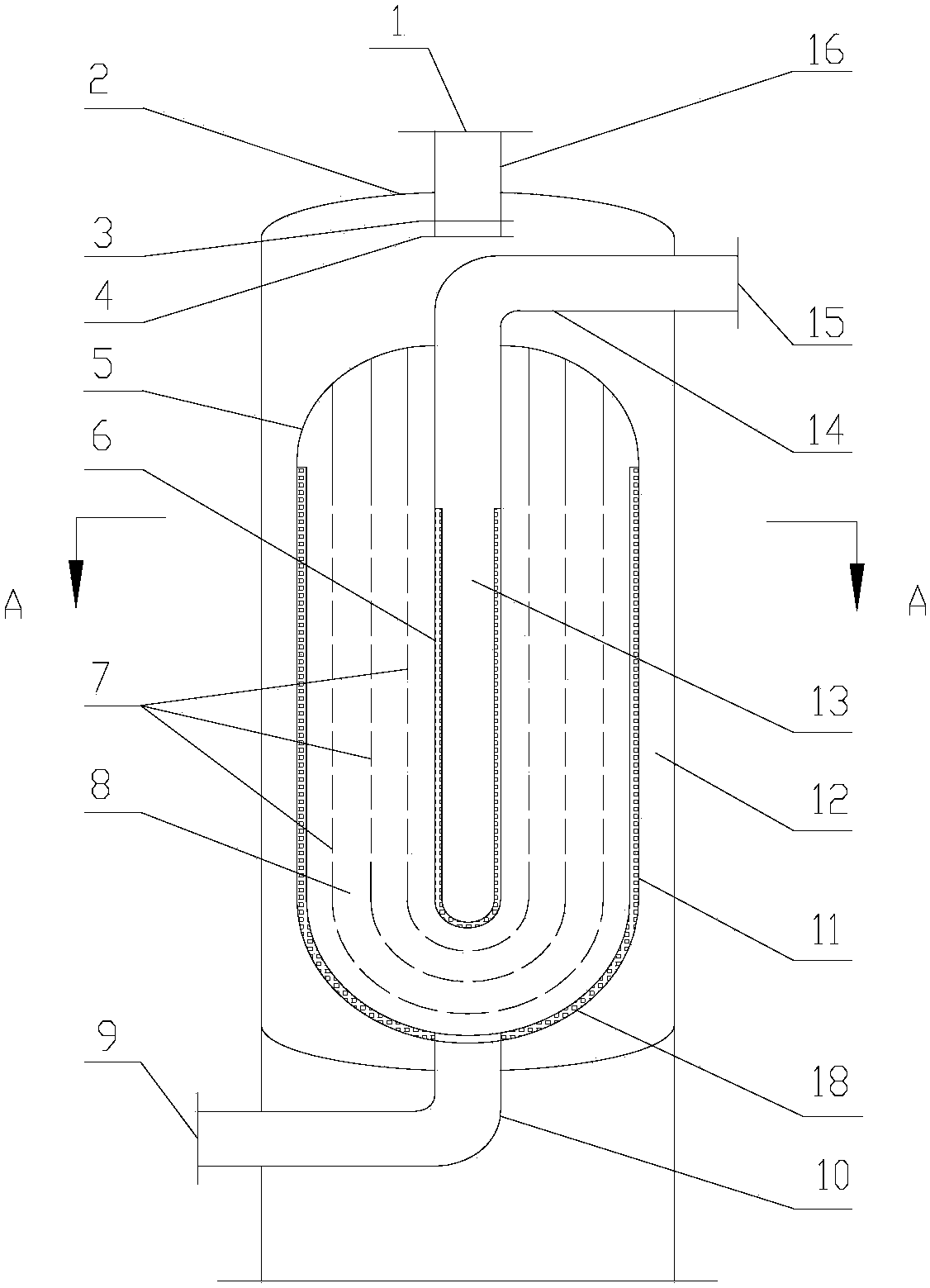

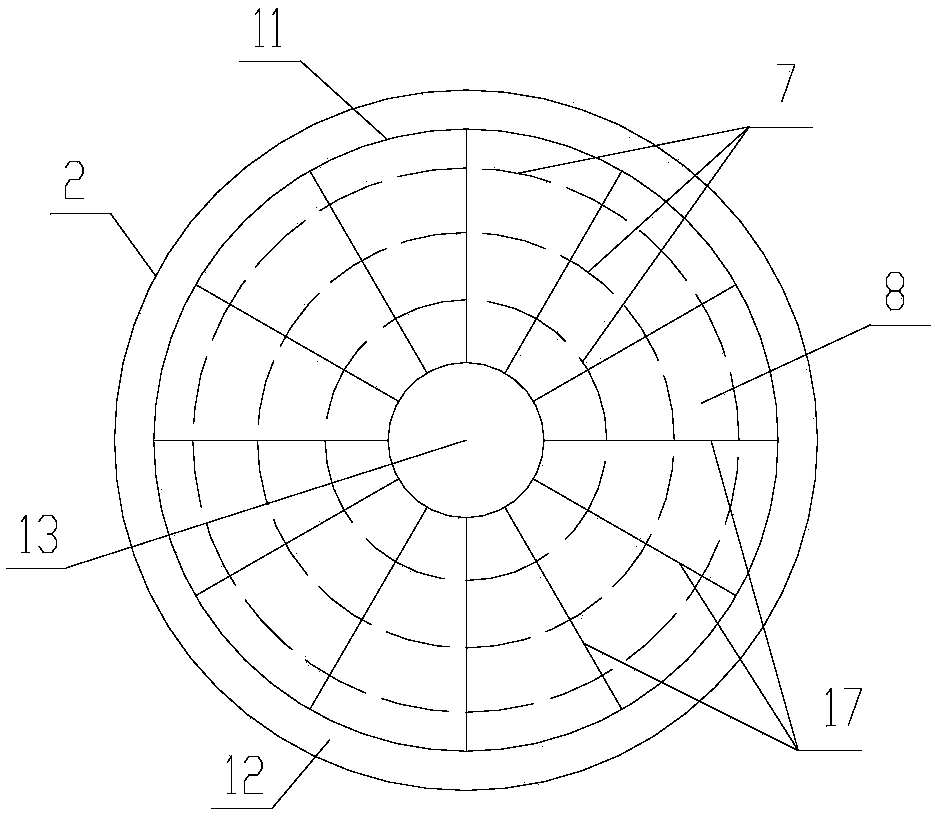

[0049] Such as figure 1 As shown, the multi-bed axial radial reactor used in this embodiment includes a cylindrical sealed pressure-bearing shell 2, an air inlet pipe 16 extending from the top of the shell 2 into the inside of the shell, and is arranged in the shell 2 The axis coaxial with the casing 2 below the inlet pipe 16 is radial to the catalytic reaction zone 8 and the outlet pipe 14 . The upper part of the intake pipe 16 has an air inlet 1 , the lower part is provided with a first gas distributor 3 , and the lower part of the first gas distributor 3 is provided with a second gas distributor 4 . The catalytic reaction zone 8 in the radial direction of the axis is a cylindrical accommodation space that can accommodate the catalyst bed. The outer shell of the accommodation space is formed by a side wall 11, a top cover 5 and a bottom cover 18. The top cover 5 is a spherical head, and the side wall 11 and the back cover 18 have a perforated structure, and the back cover 1...

Embodiment 2

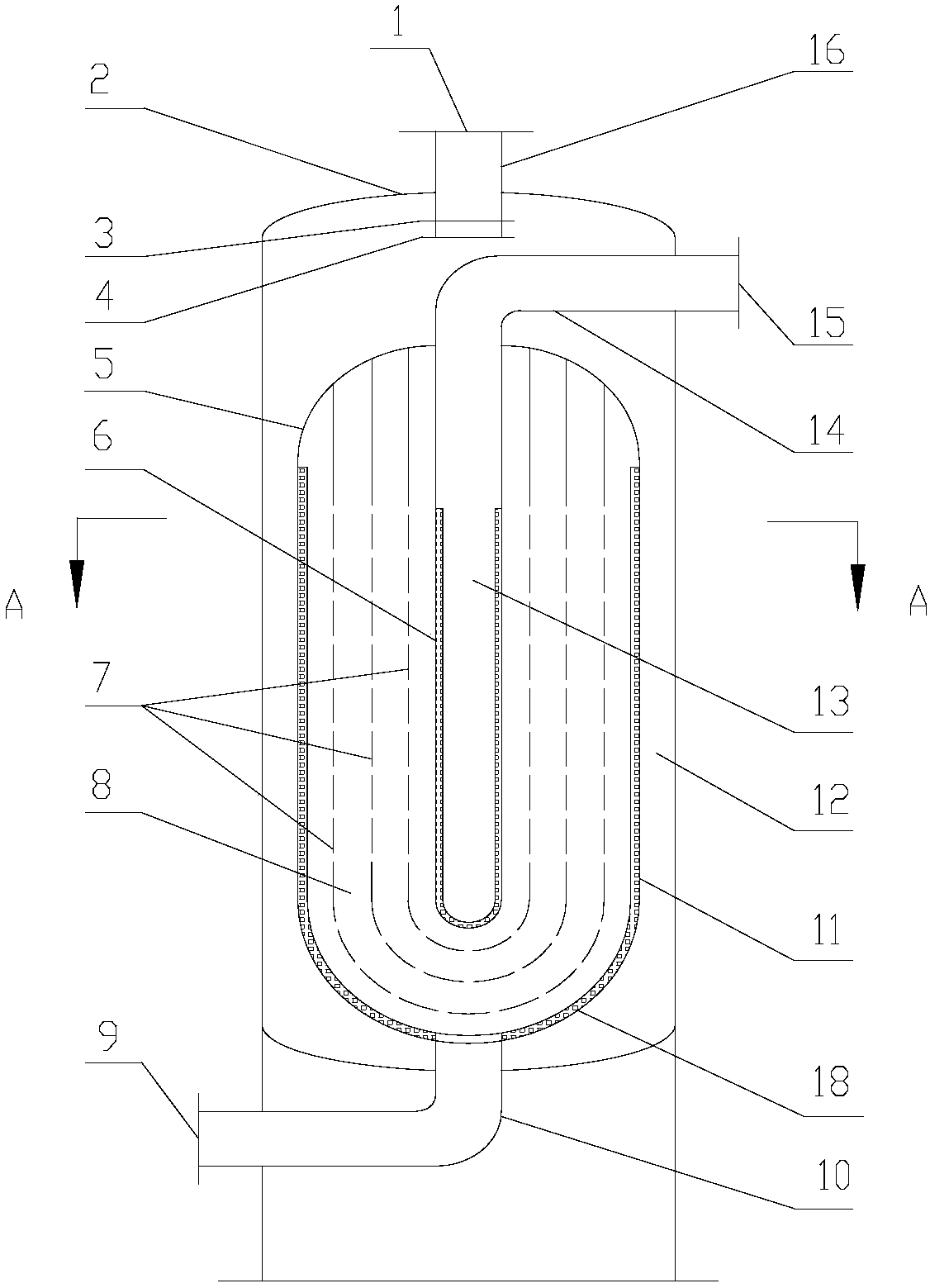

[0056] Such as image 3 , Figure 4 As shown, the reactor of this embodiment is the same as the reactor shell inner diameter, the height of the catalytic reaction zone, the opening and other structural parameters of the reactor in embodiment 1. The difference from Example 1 is that no partition is set in the reactor of this example. The reactor of this embodiment can also be used for methanation reaction. The process conditions adopted in Example 1 are the same.

[0057] From the perspective of the temperature distribution of the catalyst bed, the average distance between the hot spot position of the bed and the side wall 11 is 255mm, and the hot spot value is 923K. Table 2 shows the comparison between the multi-bed axial radial reactor in this embodiment and the radial reactor in the prior art. Likewise, both reactors had the same catalyst loading. It can be seen from the three indicators of bed layer uniformity, hot spot position and CO conversion rate that the reactor ...

Embodiment 3

[0061] Such as Figure 5 , Figure 6 As shown, the reactor of this embodiment is the same as the reactor shell inner diameter, the height of the catalytic reaction zone, the opening and other structural parameters of the reactor in embodiment 1. The difference from Example 1 is that no gas redistribution plate is provided in the reactor of this example, and the number of partitions is 9, and the angle between adjacent partitions is 40°. The reactor of this embodiment can also be used for methanation reaction. The process conditions adopted in Example 1 are the same.

[0062] From the perspective of the temperature distribution of the catalyst bed, the average distance between the hot spot position of the bed and the side wall 11 is 257mm, and the hot spot value is 923K. Table 3 shows the comparison between the multi-bed axial radial reactor used in this example and the radial reactor in the prior art. Likewise, both reactors had the same catalyst loading. It can be seen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com