Fancy siro spun yarn and production method thereof

A technology of siro spinning and siro spinning, applied in the field of spinning, to achieve the effect of novel and unique style, good drape and good anti-wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

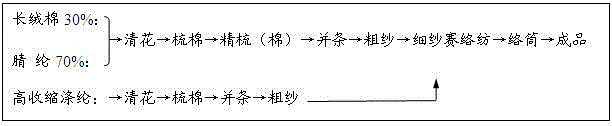

Method used

Image

Examples

Embodiment 1

[0023] A fancy siro-spun yarn with a yarn count of 32 pounds. The yarn for knitting is made of thermoplastic high-shrinkage polyester, acrylic fiber and long-staple cotton. The specification is: polyester / acrylic / cotton 32SK.

[0024] This product adopts siro-spinning AB yarn technology and adopts two kinds of rovings of different materials, among which A yarn is a blend of 30% cotton fiber and 70% acrylic staple fiber, and B is 100% thermoplastic high-shrinkage polyester staple fiber. The weight ratio of the two roving materials of A and B is 50%:50%.

[0025] The thermoplastic high-shrinkage polyester staple fiber can shrink by about 30% after being dyed and finished at a temperature above 100°C, so the structure of the yarn B shrinks obviously, and the structure of the yarn A hardly shrinks, so that the structure of the yarn A protrudes and appears on the cloth surface . Cotton fiber in yarn structure A is dyed with reactive dyes, and the shrinkage polyester in yarn struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com