Electric control equipment facilitating circulation of hydraulic valve

A technology of electric control equipment and hydraulic valves, which is applied in the direction of mechanical equipment, valve operation/release devices, valve details, etc., can solve the problems of handle mishandling and false triggering of handles, and achieve the effect of avoiding mishandling and increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

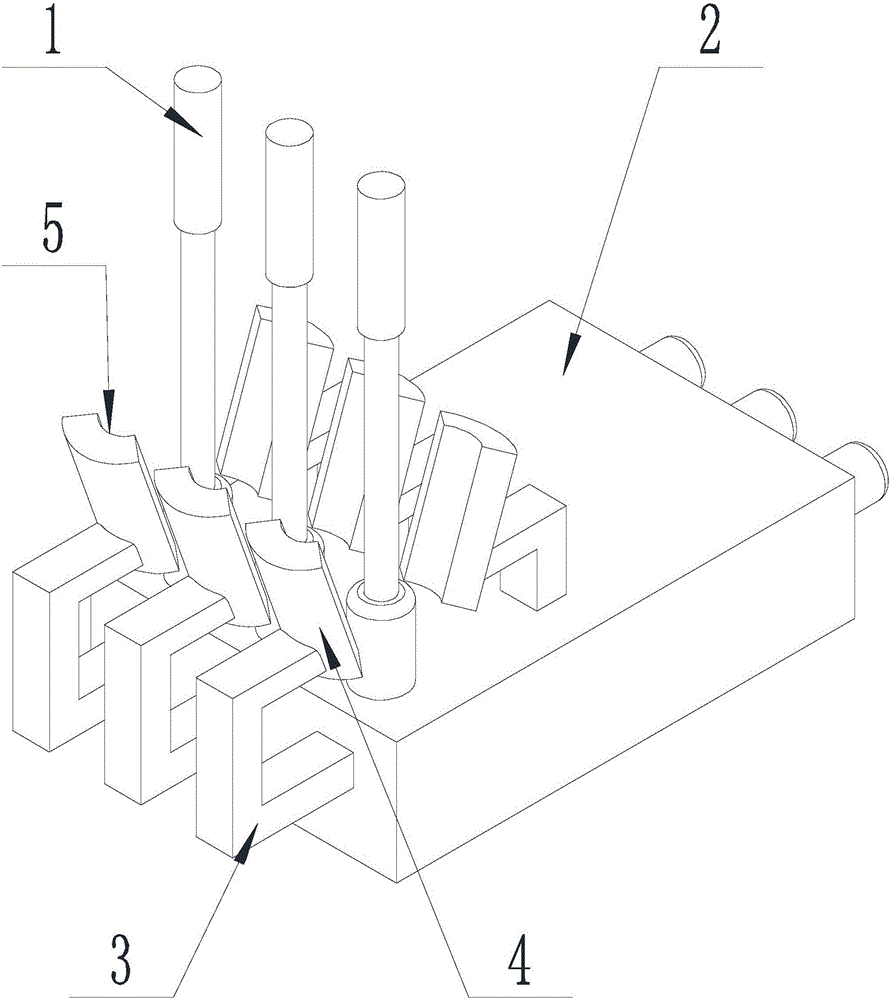

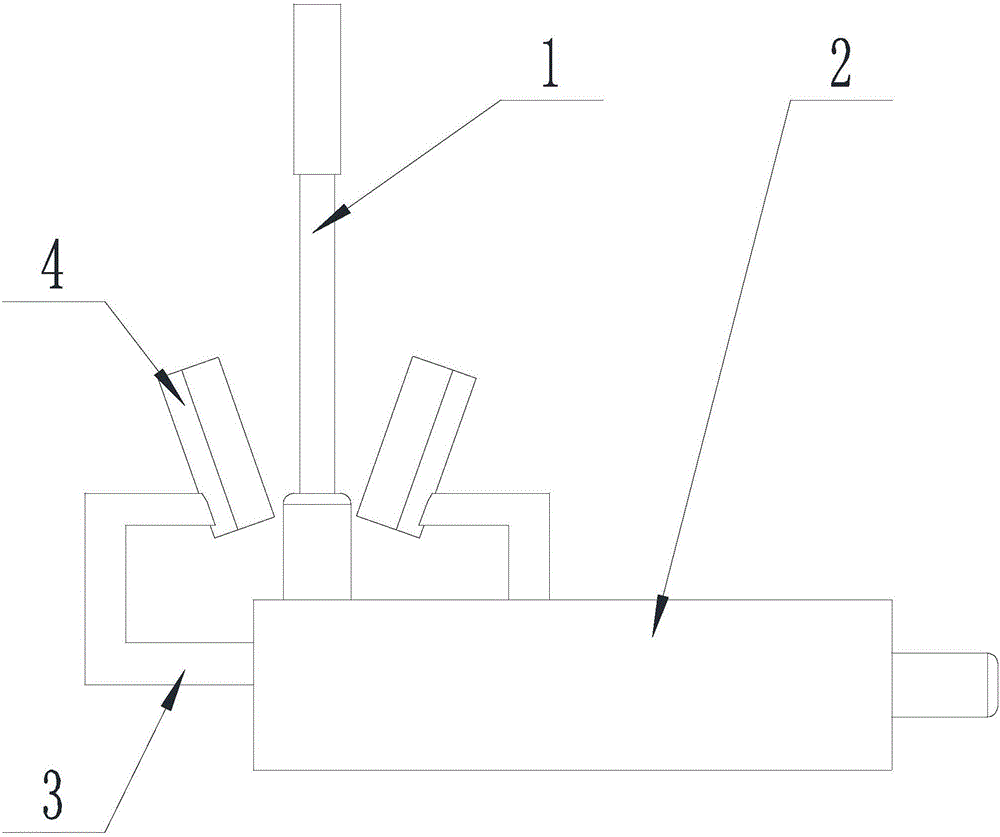

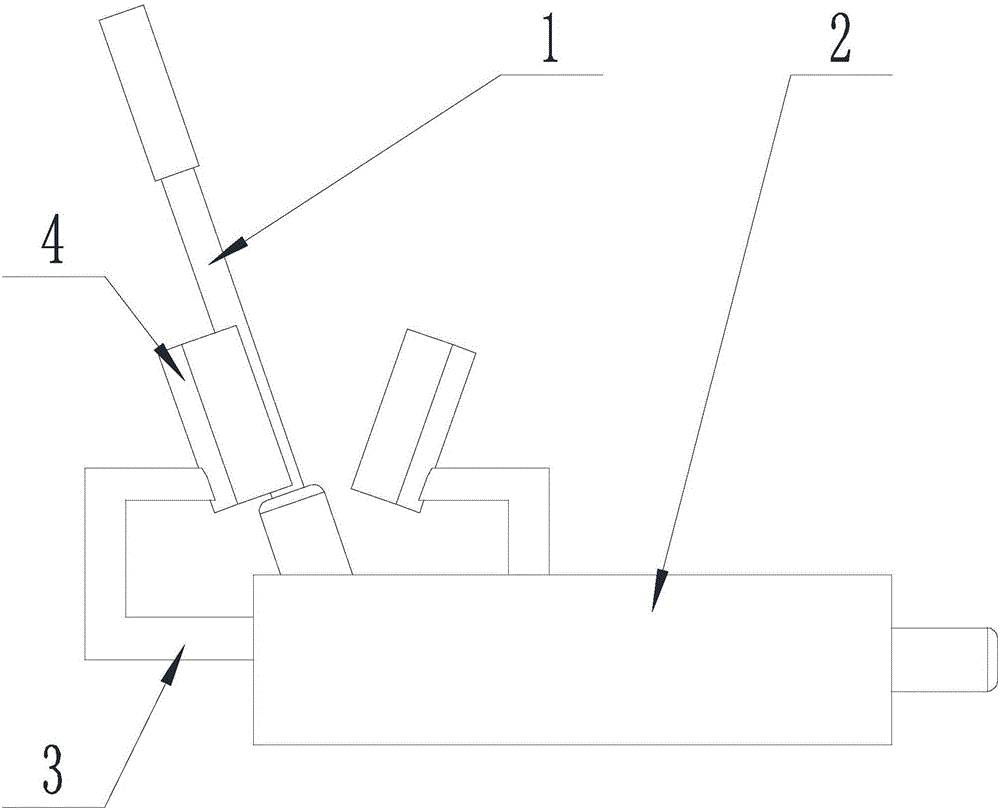

[0036] Such as Figure 1-Figure 4 As shown, the present invention facilitates the hydraulic valve circulation electronic control equipment, including a multi-way valve body 2 with several handles 1, a limit assembly is arranged on the multi-way valve body 2, and the limit assembly includes sequentially connected The support member 3 and the clamping block 4, the support member 3 supports the clamping block 4 on one side of the handle 1, and the clamping slot 5 is provided on the side of the clamping block 4 close to the handle 1. An electromagnet is arranged in the slot 5, and the handle 1 can be positioned in the slot 5 by rotating the handle 1, and is attracted by the electromagnet.

[0037] The handle 1 at each station is fixed through the structure and components such as the clamping slot 5 and the electromagnet, so as to prevent it from being accidentally touched and misoperated, thereby preventing the fluid from flowing along the wrong path; at the same time, when an obj...

Embodiment 2

[0039] The present invention is based on embodiment 1, and the present invention is further described.

[0040] Such as Figure 1-Figure 4 As shown, the present invention is an electronic control device that facilitates the circulation of hydraulic valves. The axis of the locking groove 5 passes through the rotation center of the handle 1, and the rotation of the handle 1 can make the axis of the handle 1 coincide with the axis of the locking groove 5. The axis of the locking slot 5 passes through the center of rotation of the handle 1, and the rotation of the handle 1 can make the axis of the handle 1 coincide with the axis of the locking slot 5, which can increase the contact surface between the locking slot 5 and the handle 1, thereby enabling the electromagnet to Fix the handle 1 more firmly.

[0041] Further, the cross section of the locking groove 5 is arc-shaped, and its radius is consistent with the radius of the handle 1 . The cross section of the locking groove 5 i...

Embodiment 3

[0043] The present invention is based on embodiment 1, and the present invention is further described.

[0044] Such as Figure 1-Figure 4 As shown, the present invention is an electronic control device for facilitating the circulation of hydraulic valves. The end face of the locking block 4 away from the handle 1 is arc-shaped, and the end faces the end far away from the handle 1 and protrudes outward. The end surface of the locking block 4 away from the handle 1 is arc-shaped to match the shape of the locking groove 5, so as to reduce the material required for the locking block 4 and reduce the material cost.

[0045] Further, the number of the limit components is twice the number of the handle 1, and every two limit components are a pair, and the handles 1 are respectively located in a pair of limit components, and are located at the ends of the pair of limit components. Between the card position blocks 4. In this way, no matter whether the handle is at the spool position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com