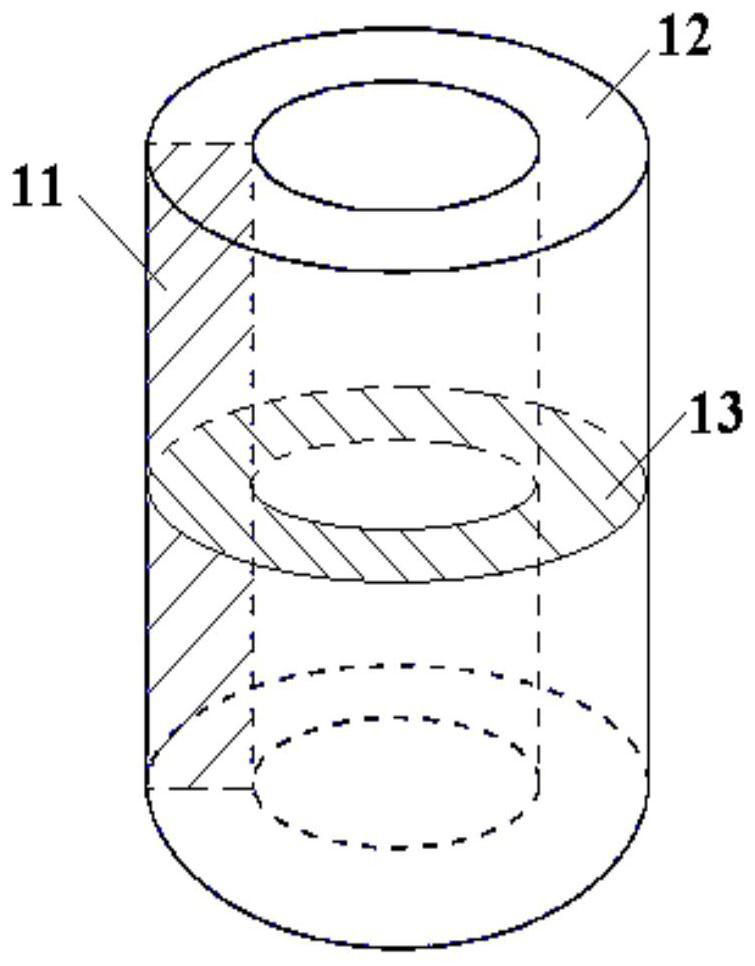

A Taylor-Couette experimental setup for solid-state media

An experimental device and medium technology, which is applied in the field of Taylor-Courette experimental devices, can solve the problems of being divided into two or more different types, and cannot realize the Taylor-Courte rheological experiment of liquid medium, so as to achieve comprehensive three-dimensional rheology The effect of form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

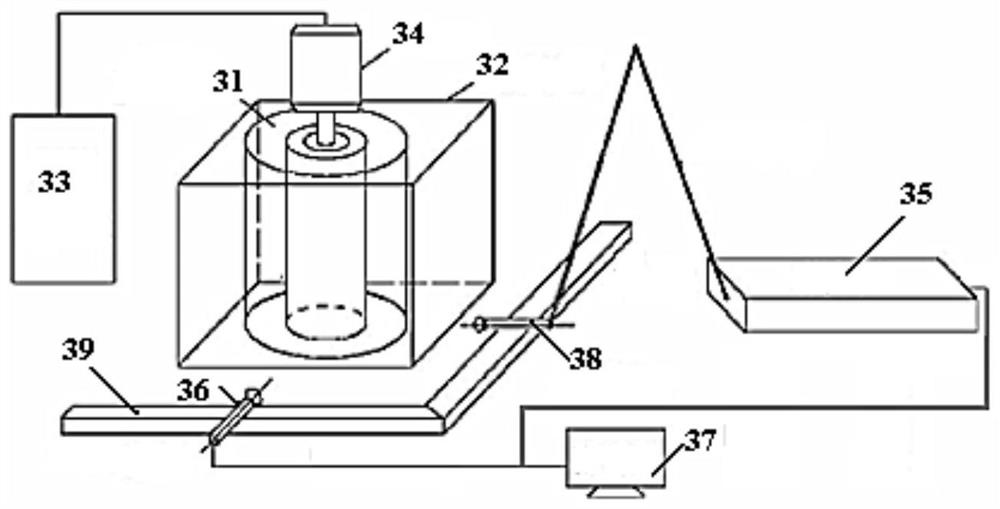

Method used

Image

Examples

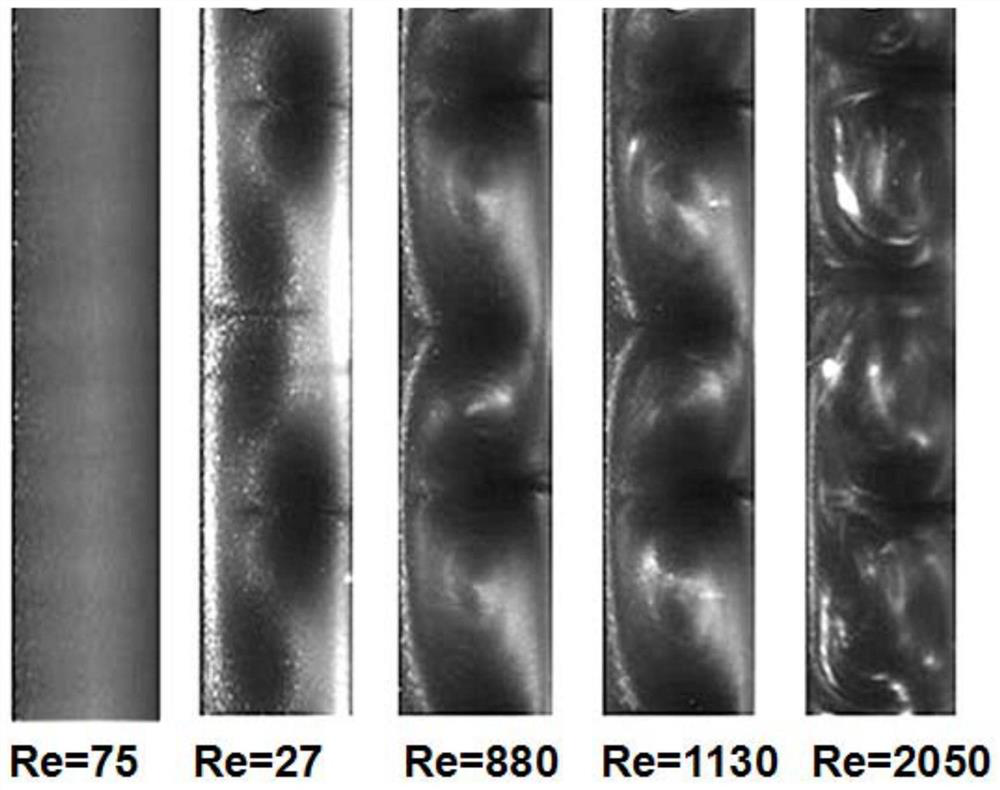

Embodiment 1

[0086] Use plasticine in red and blue colors (red corresponds to Figure 9 The brighter color in , blue corresponds to Figure 9 The darker color in the middle), respectively made the internal diameter is 20mm, the external diameter is 32mm, and the height is 10mm, and the fan-shaped cross-section cylinder with the central angle of 180 ° is loaded into the device through the above steps, and connected to each part of the device. Turn on the camera, and the gear transmission ratio used is 2:1, that is, the gear of the transmission part turns 2 times, and the gear of the main part turns 1 turn. The gear speed of the transmission part is 2 revolutions / min, the gear speed of the main part is 1 revolution / min, and the pressure exerted on the cylindrical plasticine is about 20N. After rotating for different numbers of turns, the experimental results are shown in the figure Figure 9 shown.

[0087] At the beginning, the two colors of plasticine were divided into two pieces of two...

Embodiment 2

[0089] Two materials, lead (Pb) and tin (Sn), are used to make a cylinder with an inner diameter of 47mm, an outer diameter of 51mm, and a height of 15mm, and divide the cylinder into four fan-shaped cross-section columns with a central angle of 90° Select two cylinders with a fan-shaped cross-section of lead and two cylinders with a fan-shaped cross-section of tin. The lead and tin are placed alternately to form a cylindrical sample. Such as Figure 10 shown. Put it into the sample chamber of the Taylor-Courtet experimental device of the present invention, adopt a pressurizing mechanism to pressurize the sample axially by 260KN, and after the inner and outer cylinder walls of the sample chamber are relatively rotated for 1 circle, take out the sample, and mechanically carry out the cross-section of the sample. Grinding and polishing, using a microscope to observe the flow form of the metal on the partial circular cross-section, the experimental results are as follows Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com