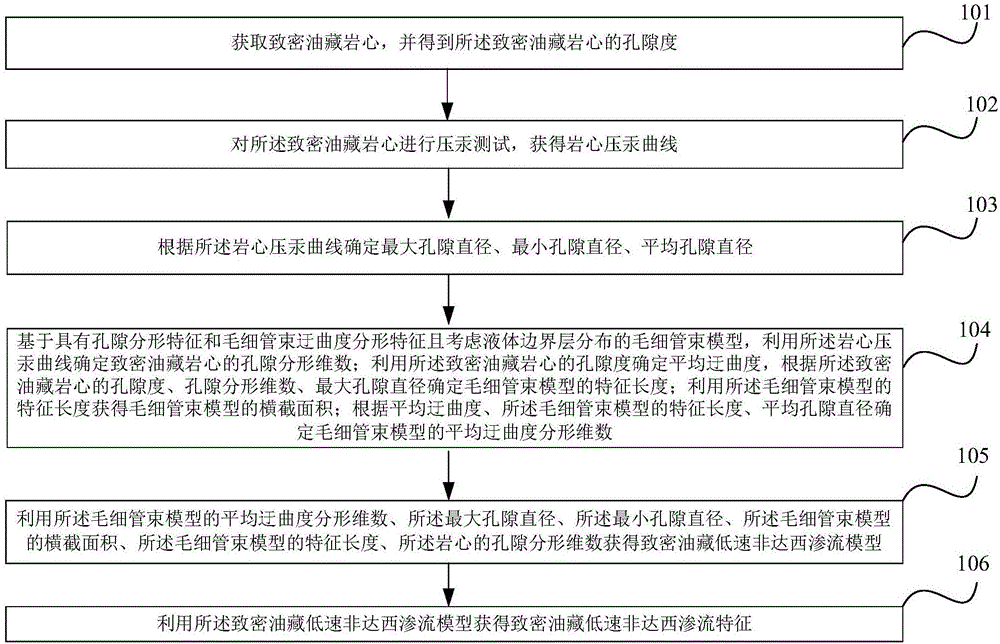

Method and device for characterizing low-speed non-Darcy seepage characteristics of dense oil deposit

A tight oil reservoir, Darcy seepage technology, applied in the direction of measuring devices, surface/boundary effects, instruments, etc., can solve the problems of tight oil phase difference, high experiment cost, small seepage velocity, etc., to achieve short time-consuming and good results Accurate, low-experimental cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

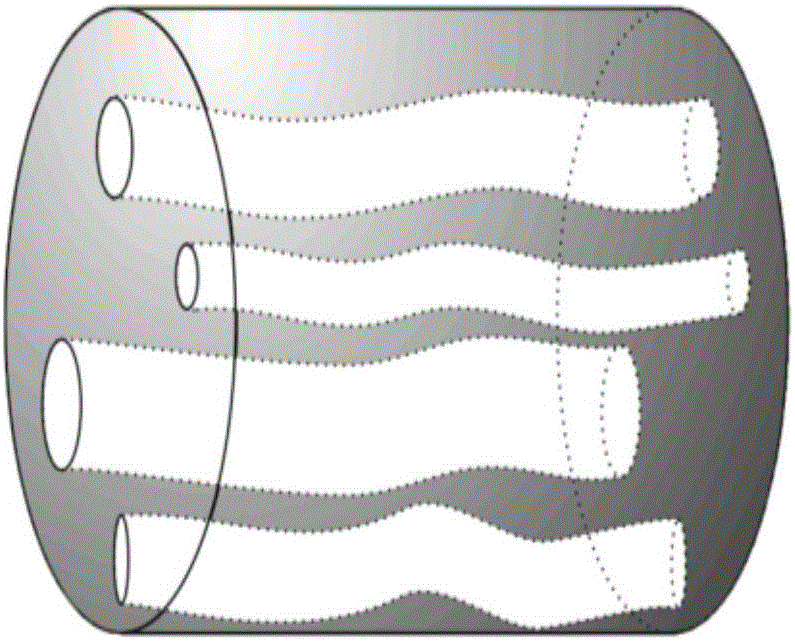

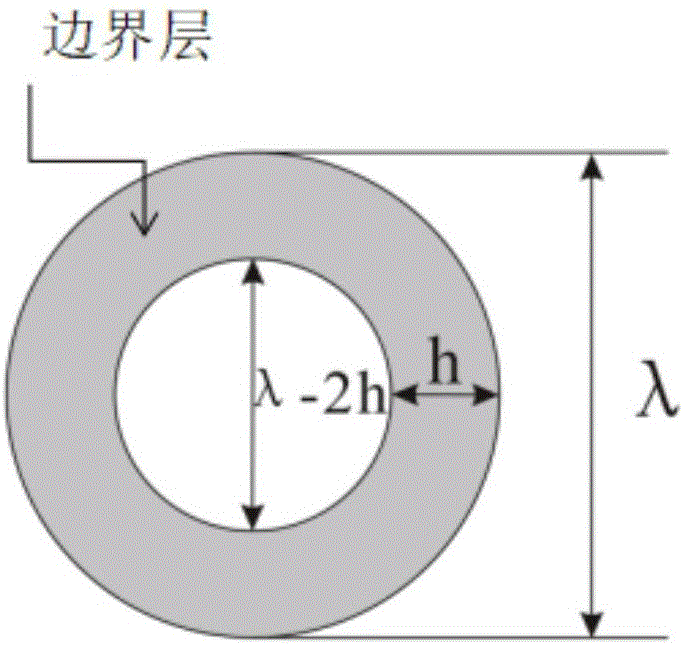

Method used

Image

Examples

Embodiment

[0140] 1. Take a tight oil reservoir core, and measure the core porosity φ=0.143 by the saturated water weighing method;

[0141] 2. Carry out mercury injection test on the core, and obtain the mercury injection curve of the core, such as Figure 5 shown;

[0142] The pore diameter λ can be adjusted by the mercury injection pressure P c get:

[0143]

[0144] The displacement pressure of this core is P cd =0.639MPa, the maximum mercury injection pressure P cmax =83.44MPa, bring in The maximum pore diameter λ can be obtained max = 2.3 μm and minimum pore diameter λ min = 0.0292 μm.

[0145] The average pore diameter of this core is:

[0146]

[0147] S Hgi is the mercury saturation at a certain time point i, S Hgi-1 is the mercury saturation at the previous time point i-1, λ i-1 is the pore throat diameter at the previous time point i-1, λ i is the pore throat diameter at a certain time point i, where i represents a certain time point.

[0148] Calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com