Material proportioning device for producing carbon brushes

A material and carbon brush technology, which is applied in the field of material batching devices for carbon brush production, can solve the problems of high manual labor intensity and achieve the effects of reducing labor intensity, ensuring health, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below by means of specific embodiments:

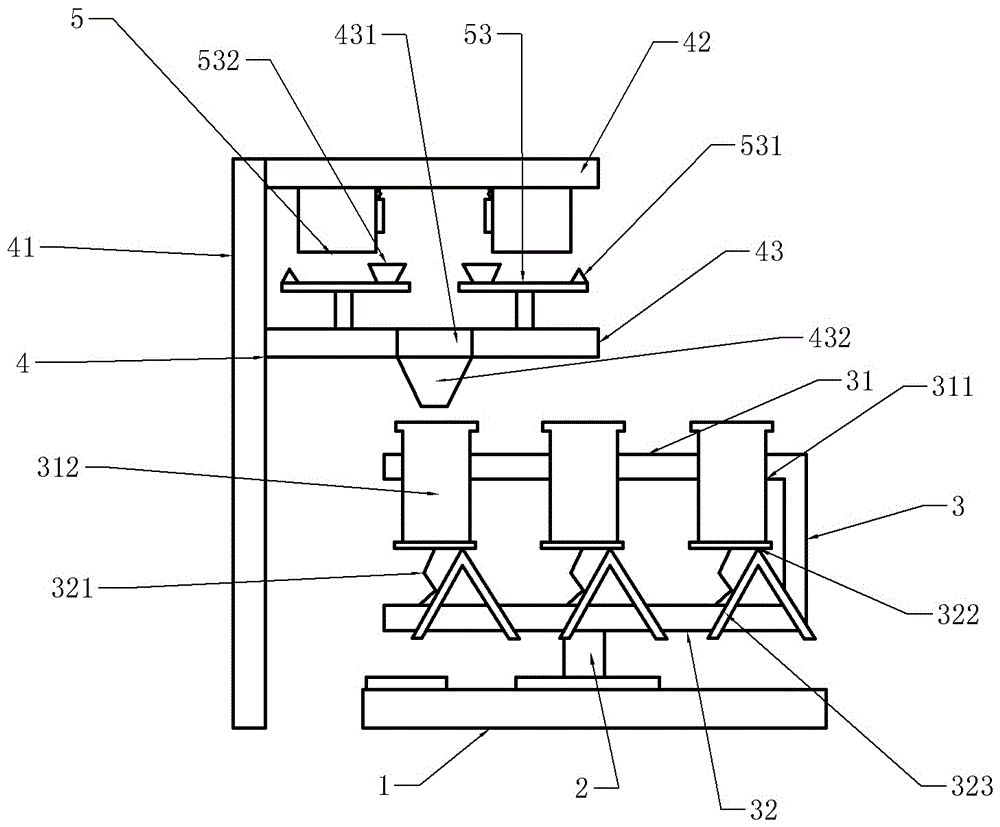

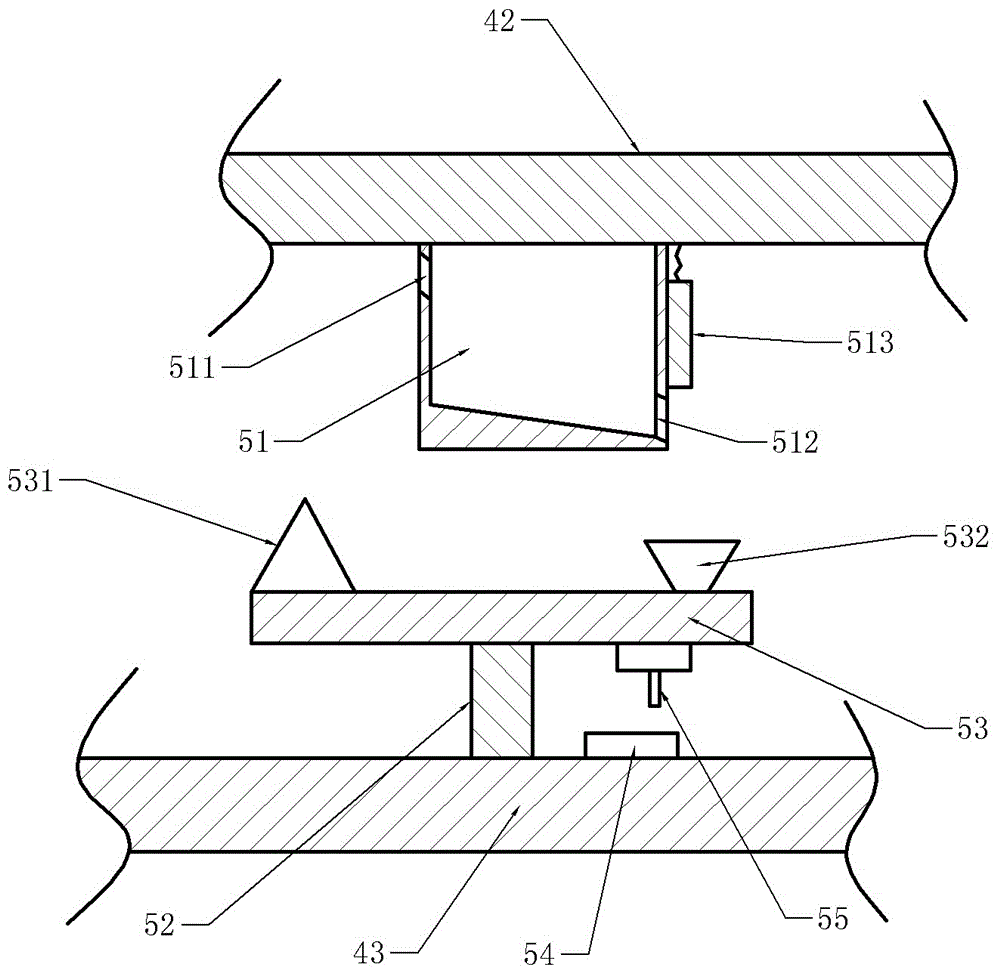

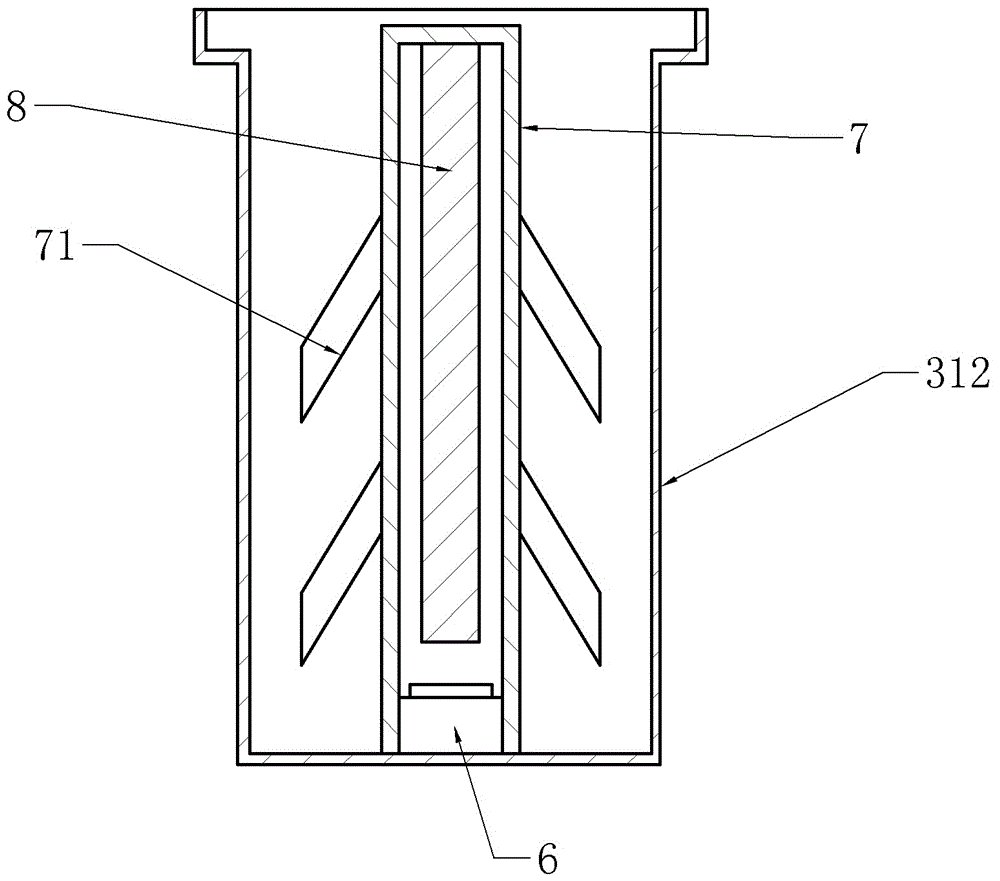

[0030] The reference signs in the accompanying drawings of the description include: workbench 1, rotating shaft 2, turntable 3, first turntable 31, installation hole 311, material collecting barrel 312, second turntable 32, elastic member 321, pressure bearing fast 322, conductive sheet 323, support frame 4, vertical bar 41, first horizontal plate 42, second horizontal plate 43, batching hole 431, material guide barrel 432, batching part 5, material storage box 51, feed inlet 511, discharge outlet 512, Material blocking plate 513, support block 52, balance plate 53, weighing block 531, feeding box 532, electromagnet 54, conductive wire 55, driver 6, stirring shaft 7, stirring blade 71, pressing bar 8.

[0031] Such as figure 1 As shown, the material batching device for carbon brush production includes a batching mechanism on the left side and a transmission mechanism on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com