Motor rotor, permanent magnet motor and compressor

A technology of motor rotor and permanent magnet motor, which is applied in the field of compressors, can solve problems such as insufficient power density, and achieve the effect of increasing power density and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

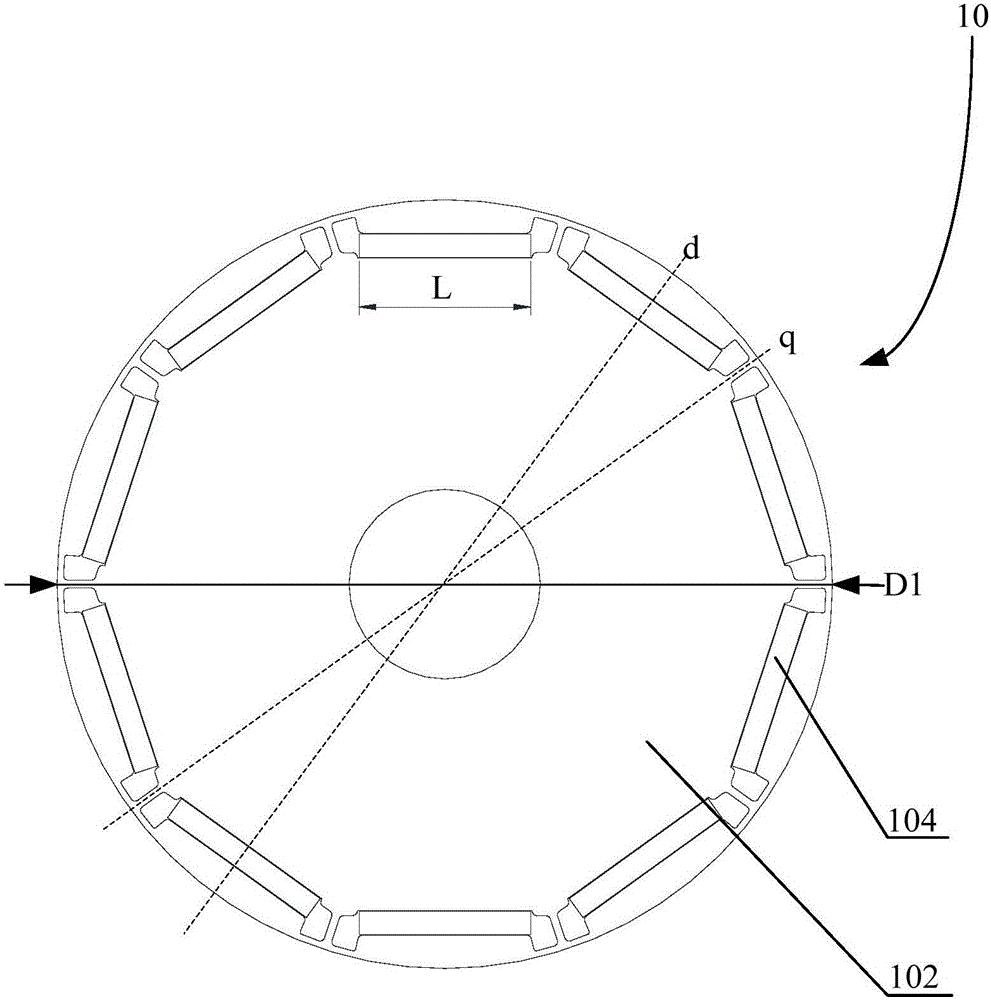

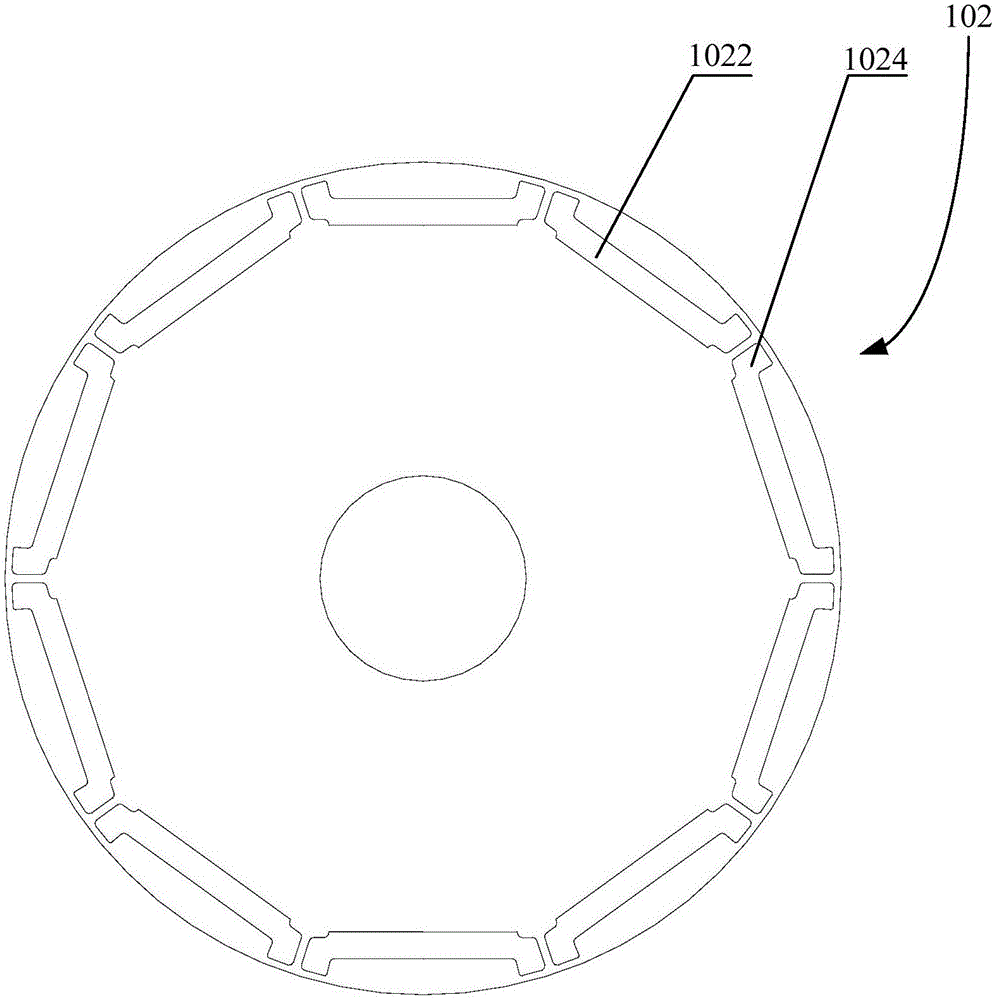

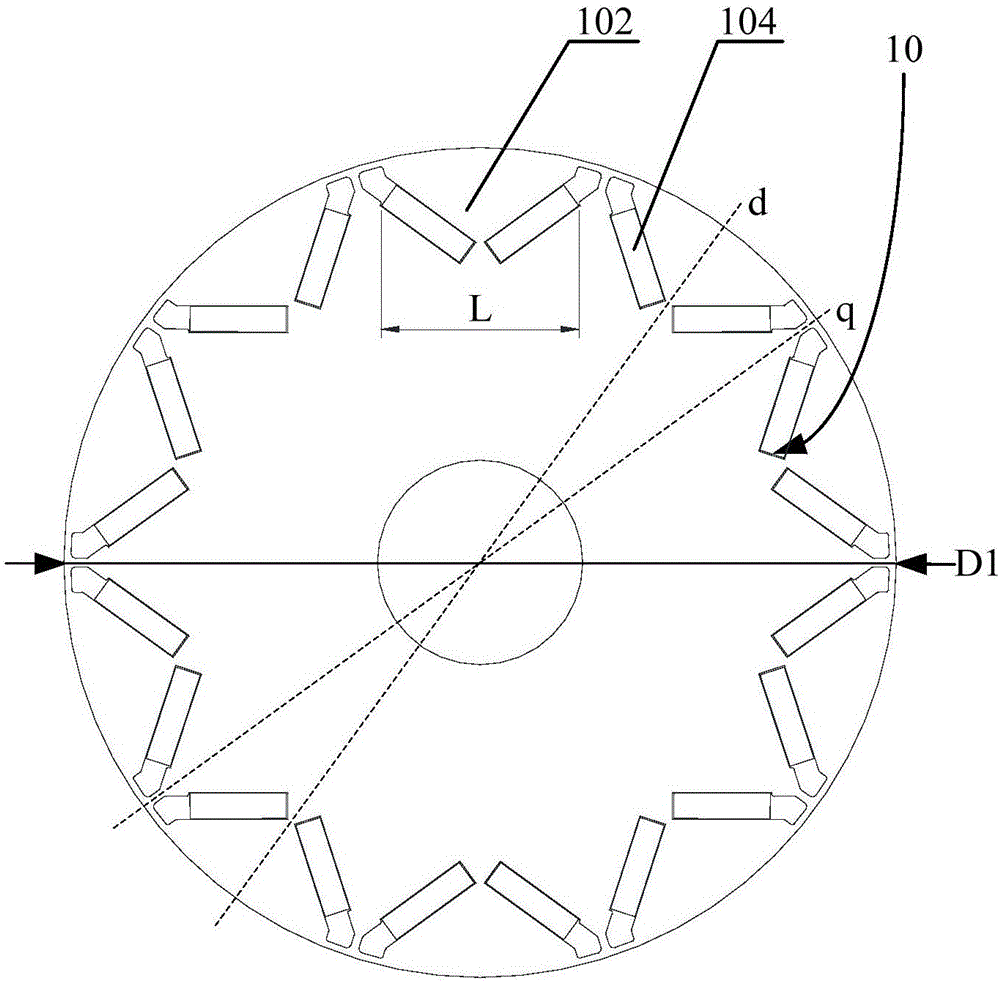

[0058] Such as Figure 1 to Figure 5 As shown, the motor rotor 10 according to the embodiment of the present invention is suitable for a compressor, including: a rotor core 102, a plurality of sets of receiving grooves 1022 are opened on the end surface of the rotor core 102 along the circumference of the rotor core 102; The permanent magnets 104 are correspondingly embedded in multiple sets of accommodation grooves 1022, and the permanent magnets 104 in each set of accommodation grooves 1022 form magnetic poles, wherein the number of magnetic poles is greater than or equal to 8 and less than or equal to 12, and the distance between the two ends of the magnetic poles is The distance is L, and the outer diameter of the rotor core 102 is D1, 0.18×D1≤L≤0.28×D1.

[0059] In this embodiment, the motor rotor 10 includes a rotor core 102 and a plurality of sets of accommodation grooves 1022 provided on the rotor iron core 102. The accommodation grooves 1022 are used to embed the perm...

Embodiment 2

[0072] Such as figure 1 As shown, specifically, the permanent magnets 104 under the same pole of the motor rotor 10 are arranged in a "one" shape structure, and the width of the permanent magnets 104 is L.

Embodiment 3

[0074] Such as image 3 As shown, the permanent magnets 104 under the same pole of the motor rotor 10 are arranged in a "V" shape, and the distance L between the two ends of the magnetic pole is smaller than the sum of the widths of all the permanent magnets 104 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com