Device and method for preparing optical fiber preform base material by tube outside method

An optical fiber preform and base material technology, which is applied in the field of optical fiber manufacturing, can solve the problems of large deviation in height detection at the bottom surface of the powder rod core layer, large errors in the vertical direction, affecting the quality parameters of the core layer, etc., and achieve detection accuracy. The effect of improving, reasonable and simple setting, and good quality of processed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

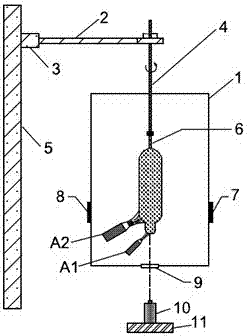

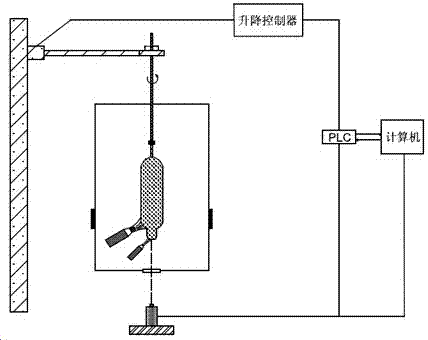

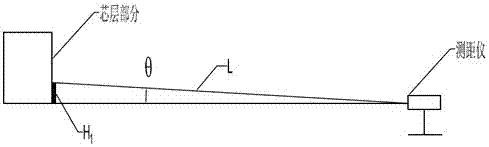

[0021] Embodiments of the device of the present invention are figure 1 , 2 Shown, comprise vertical tower frame 5, vertical tower frame vertical direction is equipped with liftable guide rail, connects lifting cantilever frame 2 by elevating seat 3 on the guide rail, and lifting cantilever frame front end installs mobile rotating boom 4, moves The bottom of the rotating boom 4 is fixed with a glass target rod 6 used for deposition, and the bottom of the moving rotating boom is correspondingly installed with a reaction chamber 1 for deposition, and the moving rotating boom extends into the reaction chamber. There is a core blowtorch A1 and a cladding blowtorch A2, the nozzles of the core blowtorch and the cladding blowtorch are inclined upwards, wherein the elevation angle of the core blowtorch is 50°, and the elevation angle of the cladding blowtorch is 40°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com