Turning transmission gear of lapper fan

A transmission device and lapping machine technology, applied in the field of cotton textile machinery, can solve the problems of increased friction of the transmission belt, unguaranteed product quality, increased consumption of machine parts, etc., achieve stable negative pressure airflow, eliminate hidden dangers of production quality, The effect of saving machine materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

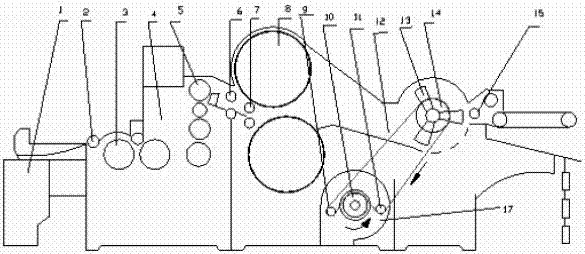

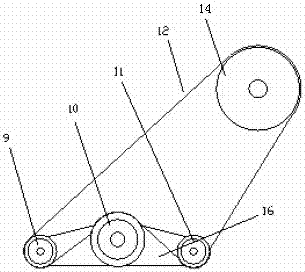

[0011] like figure 1 , figure 2 As shown, the present invention includes a cotton roll trolley 1, a cotton roll stick 2, a roll roller 3, a pressing roller 5, an anti-sticking roller 6, a cotton output roller 7, an upper and lower dust cage 8, a comprehensive beater 13, and a balance cotton device 15 , guide wheel support 16, fan base 17; described balance cotton device 15 is connected with comprehensive beater 13 entrances, and comprehensive beater 13 outlets are connected with upper and lower dust cages 8, and the cotton layer adsorbed on the upper and lower dust cages 8 passes through the cotton rollers successively 7. The anti-sticking roller 6 is connected with the compression roller 5, and the exit of the compression roller 5 is connected with the roll roller 2 through the roll roller 3 in turn, and the cotton roll stick 2 after winding the cotton roll is pushed onto the cotton roll trolley 1 . The beater pulley 14 of the comprehensive beater 13 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com