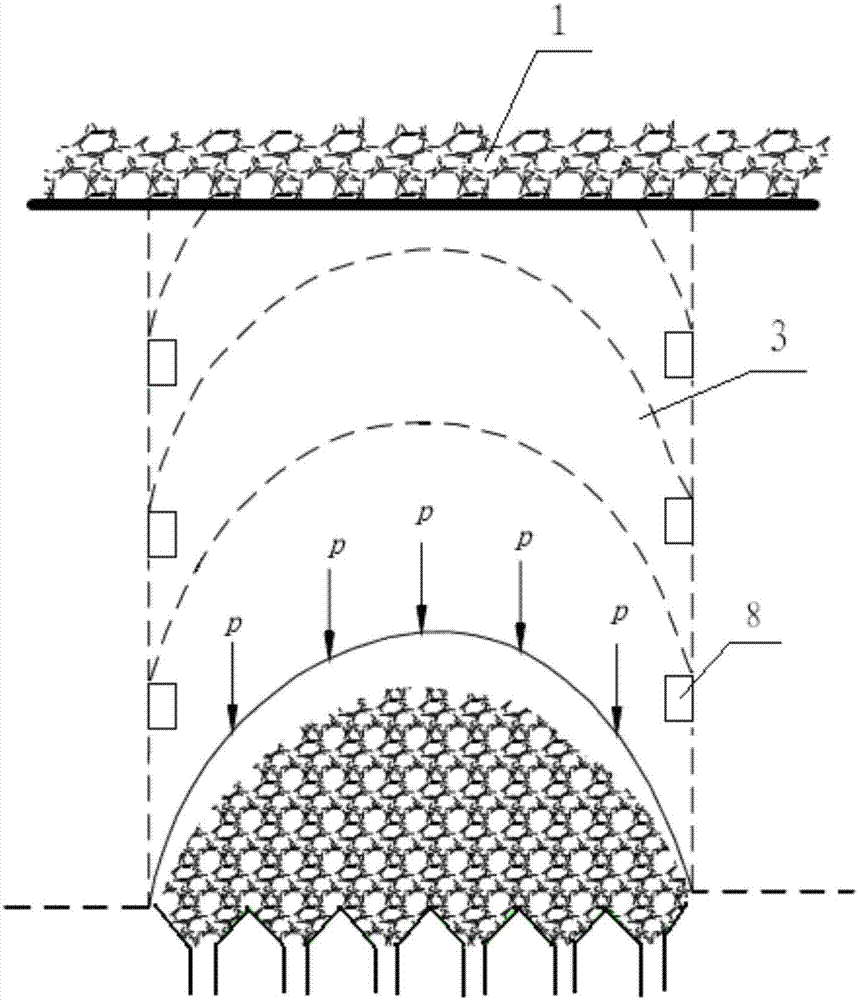

Natural caving method

A natural caving method and natural technology, applied in ground mining, earth drilling, underground mining, etc., can solve the problems of high safety accident rate and high mining cost, achieve high safety accident rate, high mining cost, and reduce blasting smoke the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

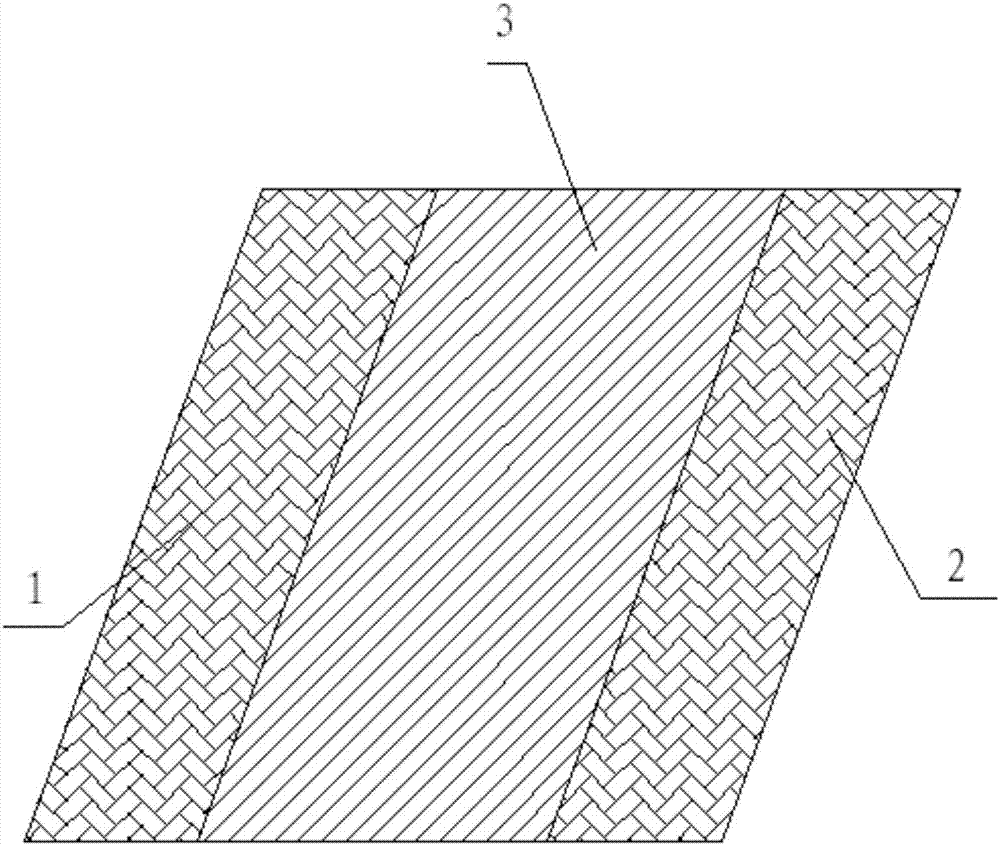

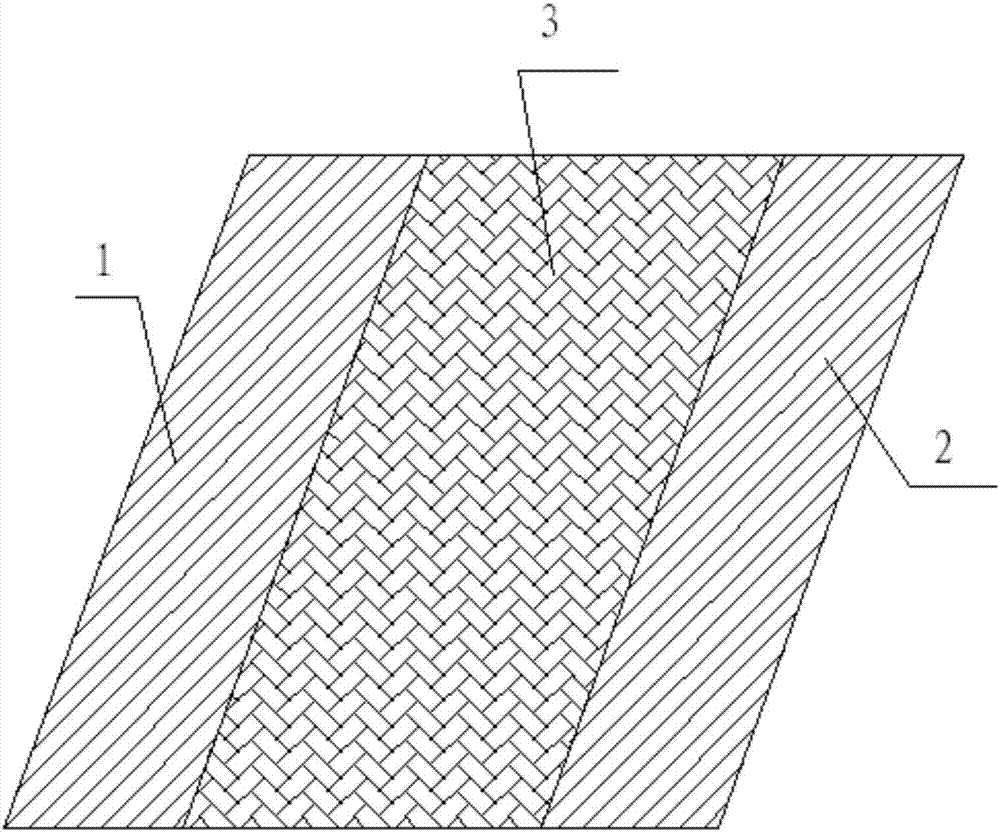

[0141] The inclination angle of the ore body 3 in an iron mine is 60°, the thickness of the ore body 3 is 40m, the average grade of ore is 35%, the size of the ore block is: the stage height is 60m, the ore block is arranged along the strike, the width is 40m, and the length is 50m. The surrounding rock 2 of the footwall of the ore body 3 is metamorphic white quartz sandstone, which is moderately stable, and the stratum's Platts coefficient is f=4~5. 3’s Platt’s coefficient f=7~8, the ore body 3 is in contact with the upper and lower wall rocks, and the ore rocks are abnormally broken.

[0142] Adopt the implementation process of natural caving method of the present invention as follows:

[0143] Step 1: Use ultrasound, geophysical prospecting, microseismic monitoring and other means to carry out geological survey of the stope, and obtain such Figure 8 and Figure 11 Show the original stope ore rock fracture development data and other geological data necessary for the minin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com