Fiber bragg grating water current velocity sensor

A technology of flow velocity sensor and optical fiber grating, which is applied in the field of sensors, can solve the problem of few water flow velocity sensors, and achieve the effects of high sensitivity, simple structure and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

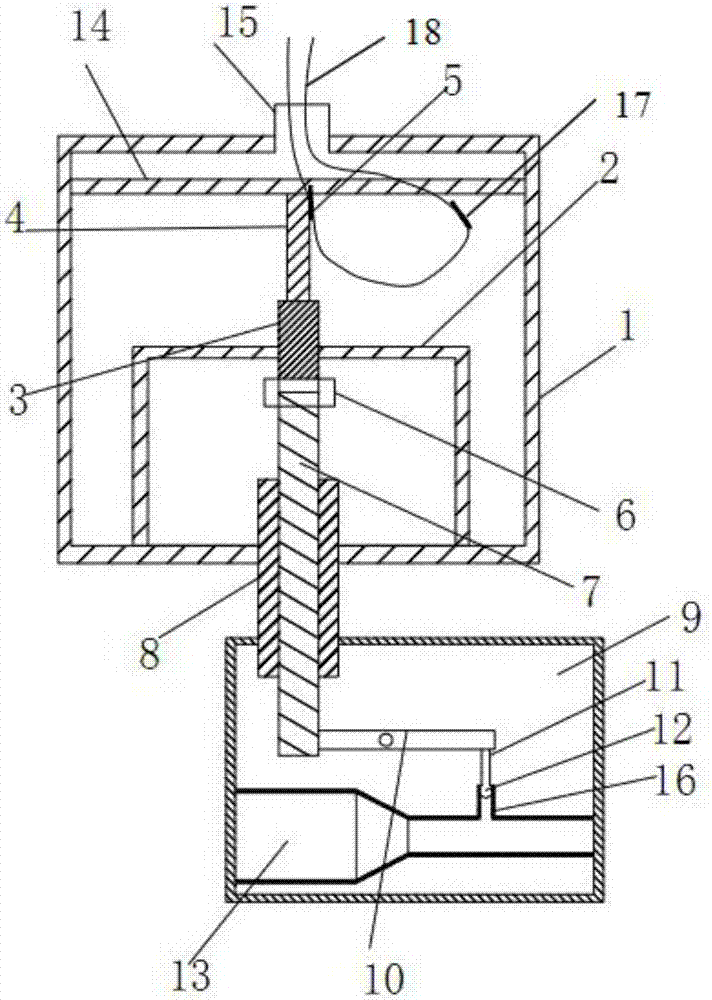

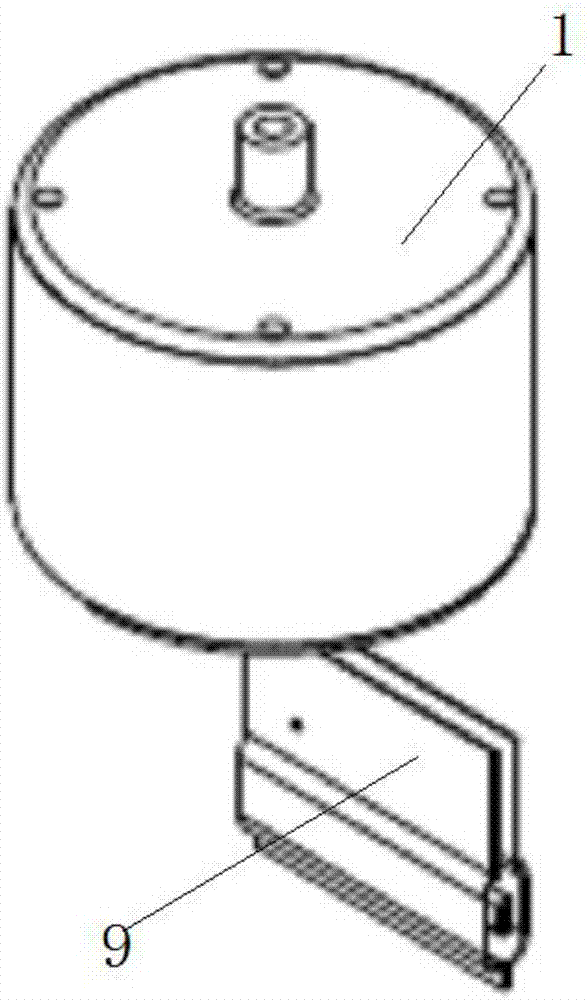

[0020] Reference Figure 1-2 , The fiber grating water flow velocity sensor includes a cylindrical hollow base 1, a support frame 2 is installed on the bottom inner wall of the base 1, and the support frame 2 is coaxially arranged with the base 1, and the top of the support frame 2 is movably sleeved with a push rod 3 to push A baffle 14 fixedly connected to the inner wall of the base 1 is installed above one end of the rod 3 protruding from the support frame 2. A spring 4 is installed between the baffle 14 and the push rod 3, and one side of the spring 4 is glued along its length. A strain grating 5 and a temperature compensation grating 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com