Frameless transformer used for automobile charging pile

A car charging, skeletonless technology, applied in the field of transformers, can solve the problems of limited space and unusable DC charging piles, and achieve the effect of improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

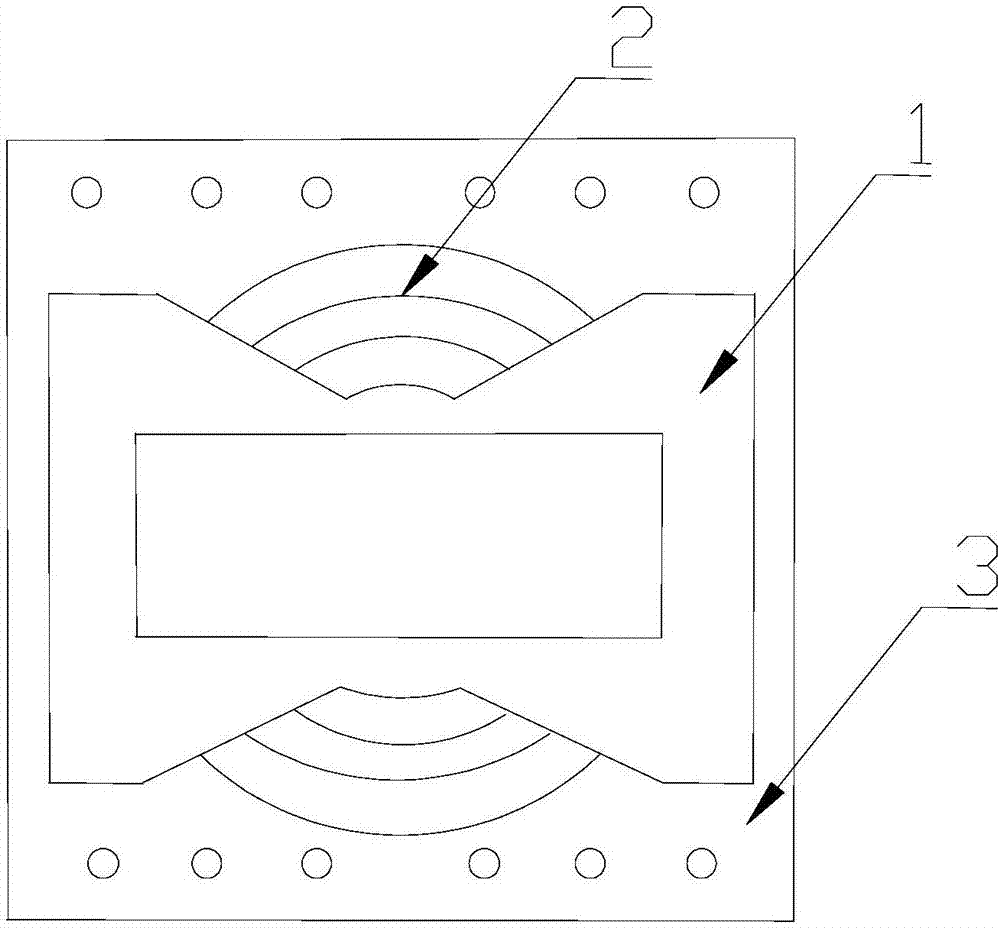

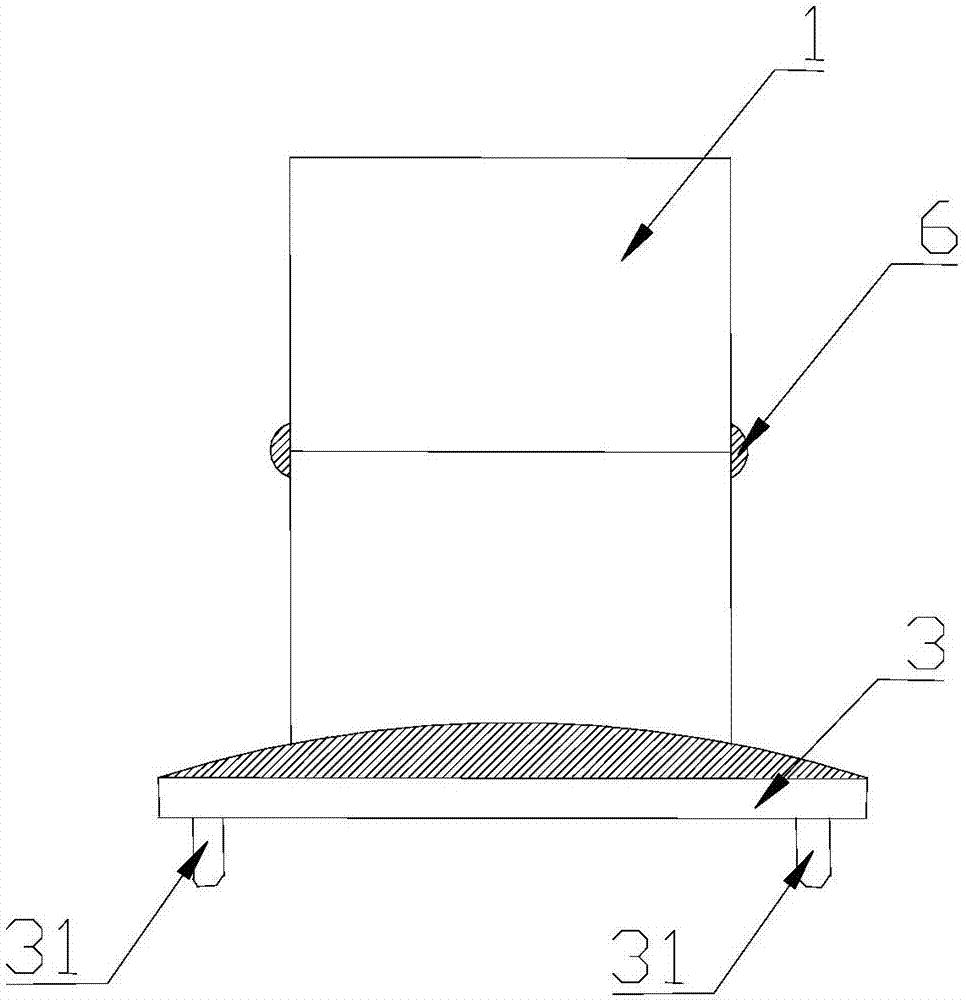

[0022] combine Figure 1 to Figure 4 , a frameless transformer for a car charging pile according to this embodiment includes a magnetic core assembly 1 and a winding coil 2 . The magnetic core assembly 1 has a magnetic core shaft with a circular cross section, and the winding coil 2 is uniformly wound on the magnetic core shaft.

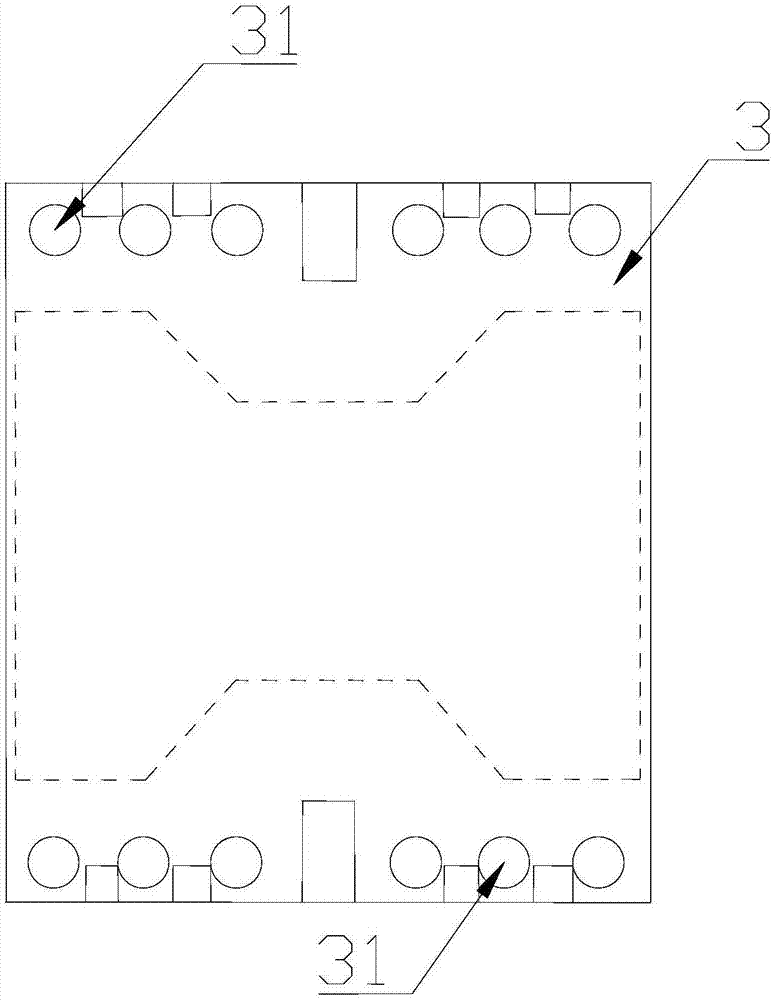

[0023] An insulating plate 3 is provided on the bottom of the magnetic core assembly in a direction perpendicular to the magnetic core shaft, and a layer of insulating tape is provided between the winding coil 2 and the magnetic core shaft. The lead wires drawn from the winding coil 2 pass through the insulating plate 3 to form pins 31. The lead wire drawn from the winding coil 2 is covered with a Teflon sleeve to the connection between the lead wire and the insulating plate. The size of the insulating board 3 is 36mm*40mm, and 12 holes are arranged on the insulating board 3 . The insulating board 3 is an epoxy resin board with a thickness of 0.5-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com