Power Module Package Structure

A power module and packaging structure technology, applied in the directions of support structure installation, closed chassis, circuit devices, etc., can solve the problem of reducing the cross-over area of the current loop without ink, etc., to reduce the cross-over area, reduce the current density, The effect of reducing loop inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

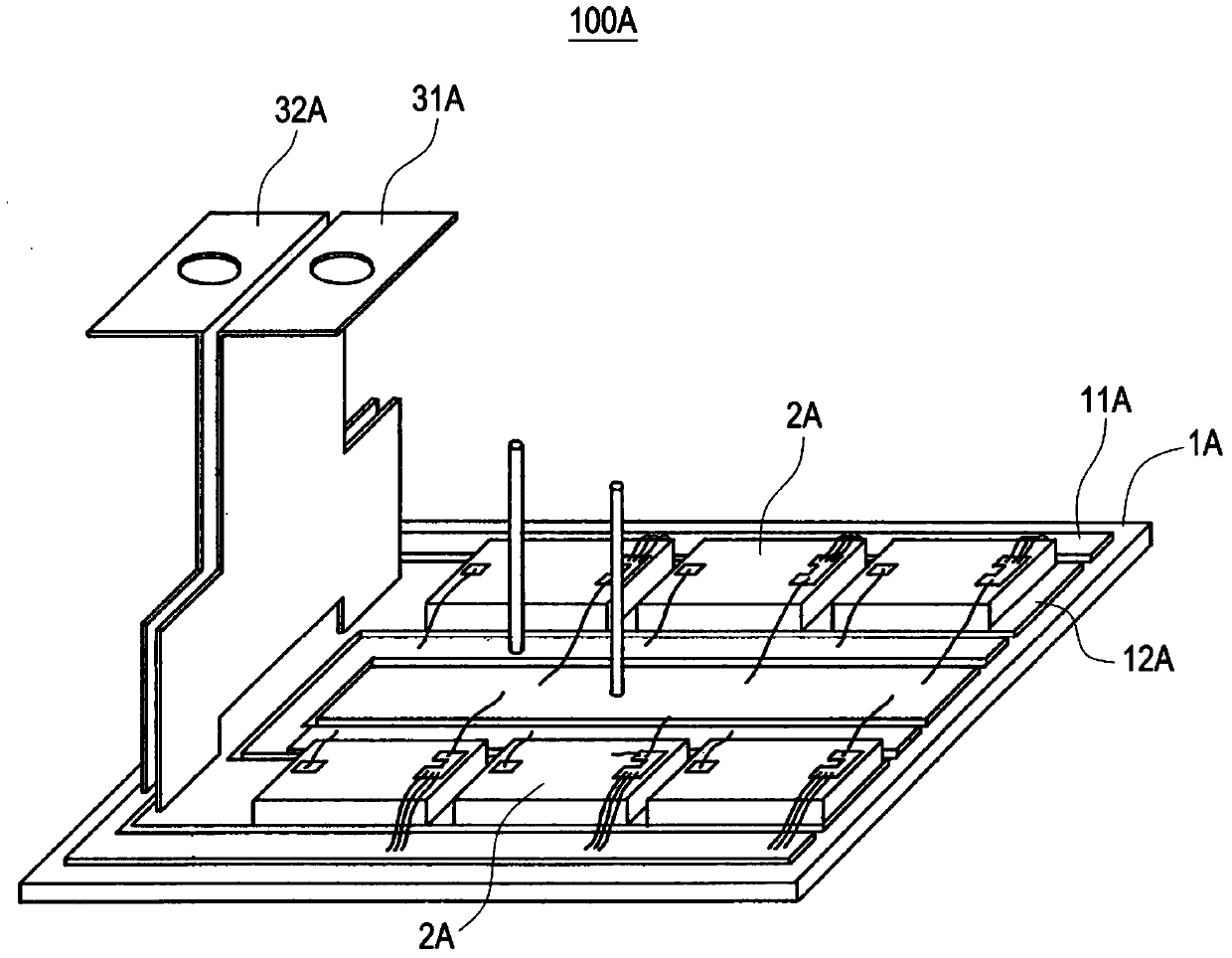

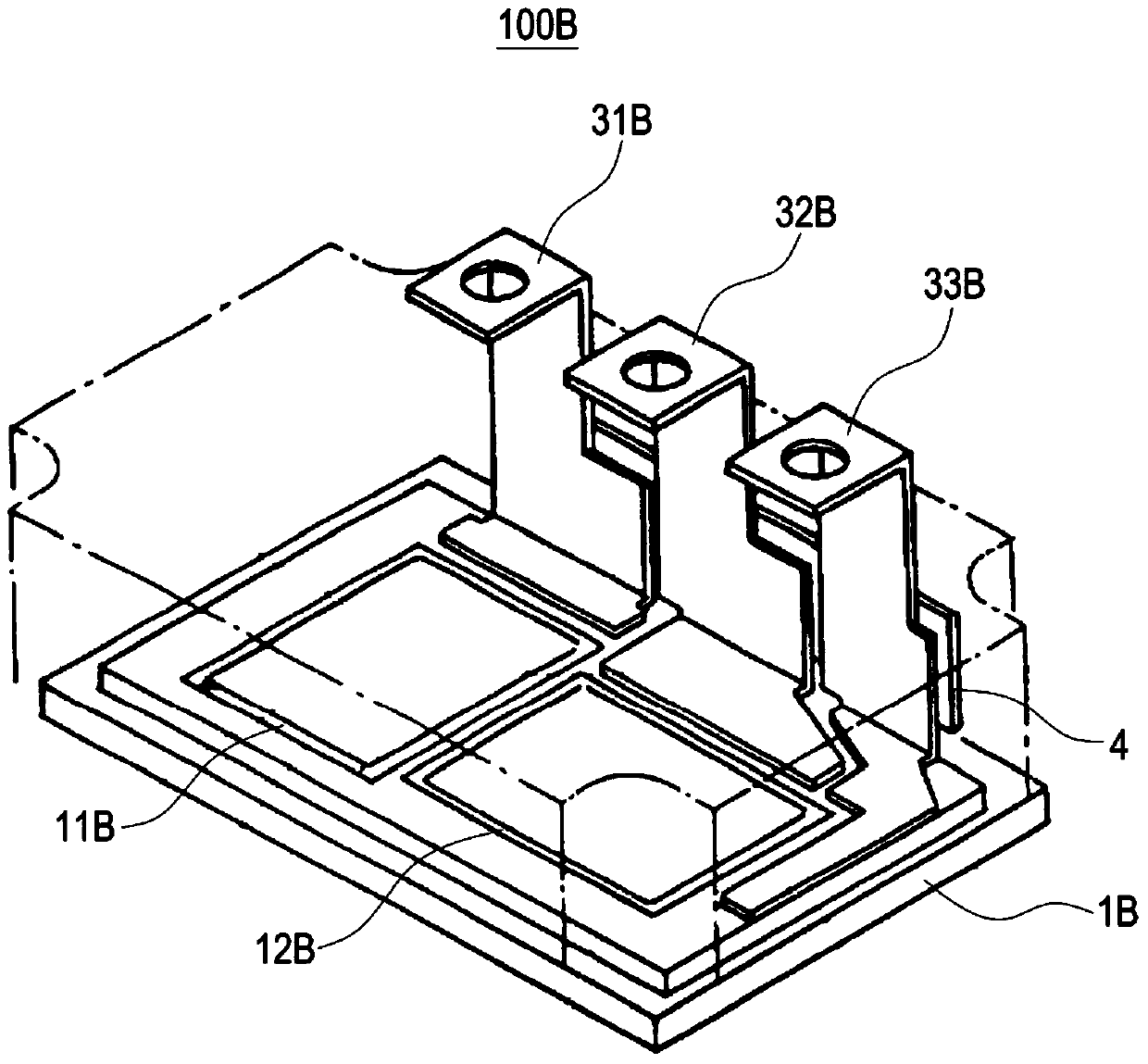

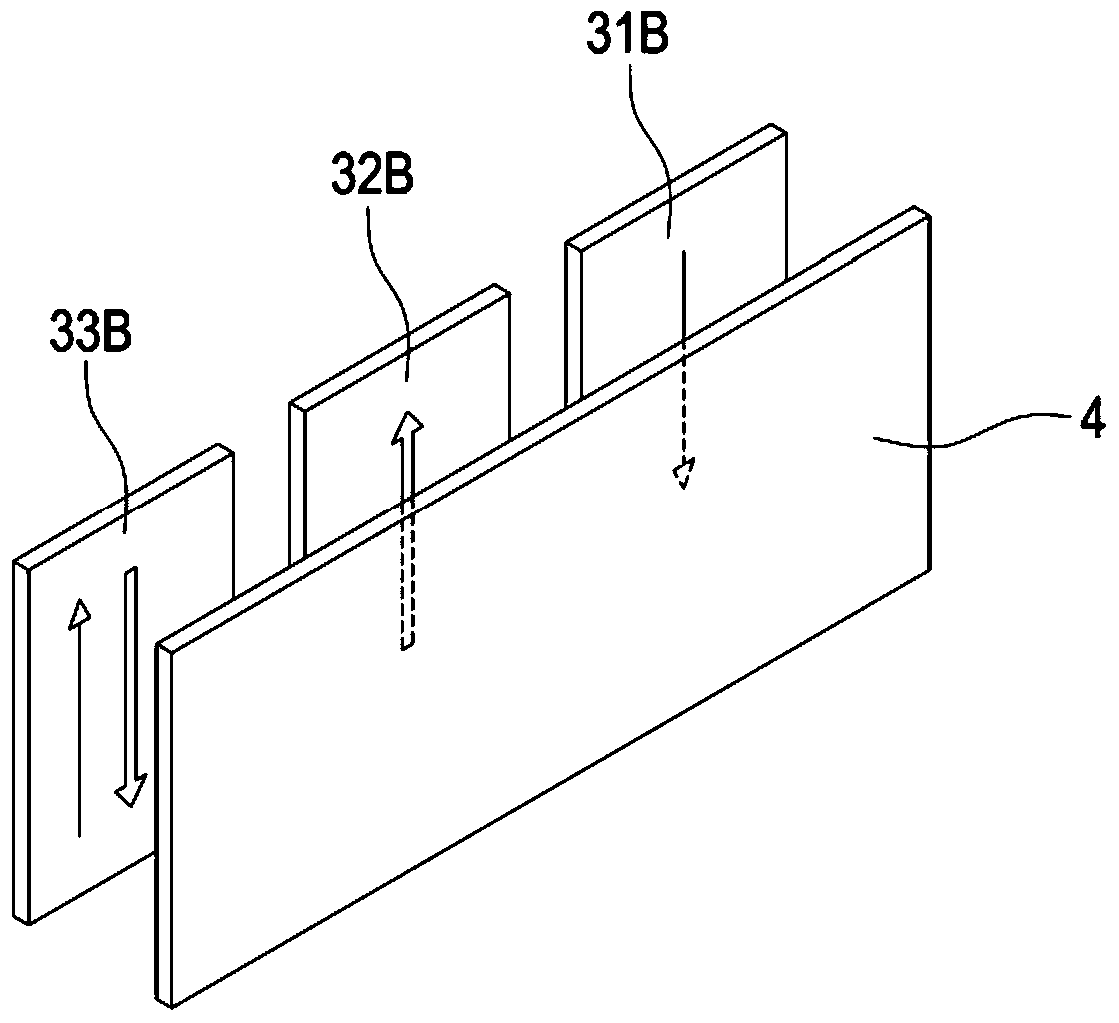

[0097] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0098] see image 3 It is a three-dimensional exploded view of the packaging structure of the power module of the present invention. The power module 100 includes: a substrate 1 , and the substrate 1 at least includes a first conductive region 11 , a second conductive region 12 and a third conductive region 13 . And there is a first connection region 14 between the first conductive region 12 and the second conductive region 13 , and the first connection region 14 is electrically connected to the first conductive region 11 through the substrate 1 . There is a second connection region 15 between the second conduction region 12 and the third conduction region 13 , and the second connection region 15 is electrically connected to the second conduction region 12 through the substrate 1 . The first conductive region 11, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com