High-speed permanent magnet motor rotor structure

A rotor structure, permanent magnet motor technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit characterized by magnetic materials, etc., can solve the difficulty of heat dissipation, poor rotor strength, noise and vibration Serious problems, to achieve the effect of improving rotor strength, reducing stress, reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

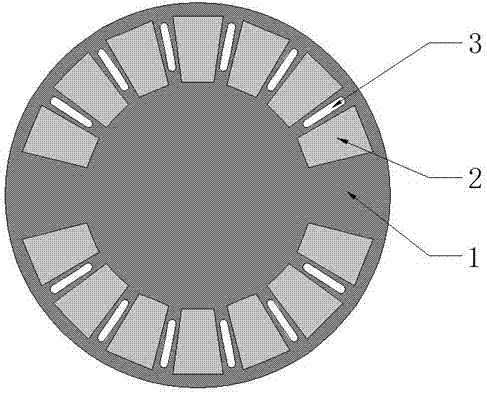

[0014] See attached figure 1 , a high-speed permanent magnet motor rotor structure, characterized in that the rotor body includes a rotor core 1, a permanent magnet 2, and a ventilation hole 3; In the core 1 , the ventilation holes 3 are distributed between adjacent permanent magnets 2 .

[0015] The motor rotor adopts a 2-pole rotor structure, the rotor core 1 is made of high-strength magnetically conductive carbon steel material, and the rotor core 1 and the rotating shaft adopt an integrated structure.

[0016] The permanent magnet 3 is divided into multiple pieces and embedded in the rotor core 1 along the circumferential direction of the rotor core 1 .

[0017] The ventilation holes 3 are distributed between adjacent permanent magnets 2 .

[0018] In the rotor structure of the present invention, the motor adopts a 2-pole rotor structure, the rotor core 1 is mad...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap