Spring coil and manufacturing process thereof

A manufacturing process and technology of coils, applied in the field of medical devices, can solve problems such as poor stacking density of coils, failure to conform to the shape of aneurysms, easy collapse and stacking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

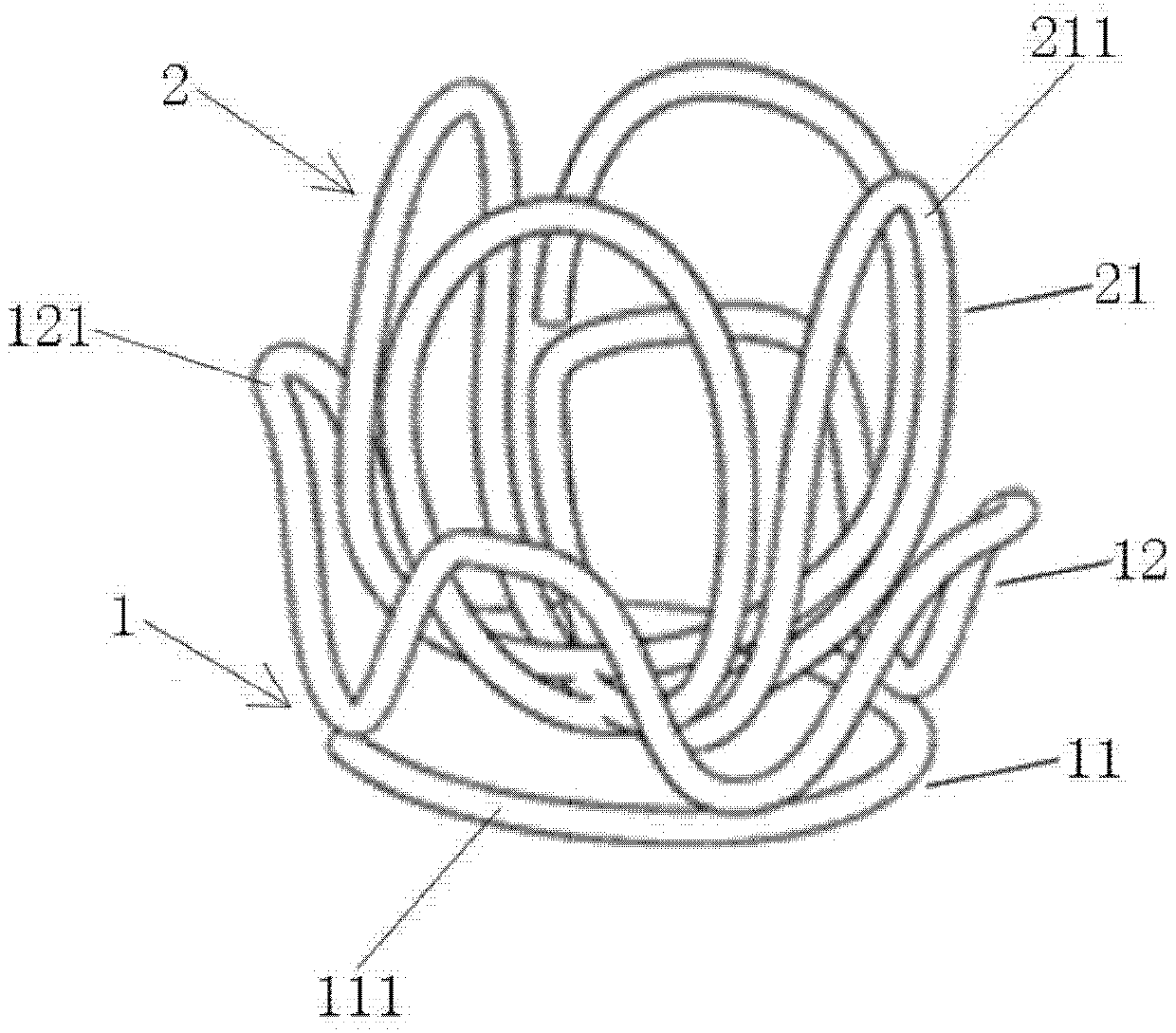

[0063] The spring ring, as a whole is as figure 1 The "flower shape" shown is made of platinum-iridium alloy. The diameter of the first-order coil for making the coil is 0.1 mm, the length is 20 cm, and 82 coils are wound per centimeter.

[0064] The manufacturing process of the spring coil is: coils of the primary form with different pitches are wound, and the coils of the primary form are loose at the distal end and tight at the proximal end. Then the spring coil of the first-order form is fixed on the image 3 In the heat treatment setting mold 3 shown, heat at 700°C for 10 minutes, cool in the furnace to 300°C, invert the spring coil, water-cool the first inner ring of the spring coil, and wait for the spring coil to cool Finally, an appropriate amount of polyester suture is tied between the coils.

[0065] like Figure 9 As shown, the spring coil provided by the second embodiment of the present invention only includes a base ring 11 and an outer ring 12 . It should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com