A graphene-cuins 2 nanocomposite photocatalyst

A-cuins2, nano-composite technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of easy dissolution, harm to the environment, expensive metal materials, etc. Effects of specific surface area, high stability and regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

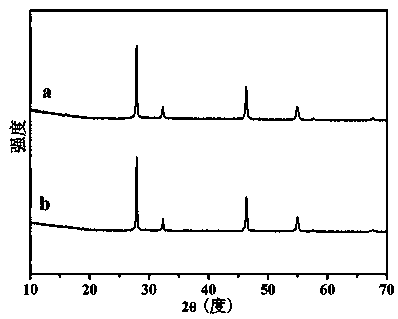

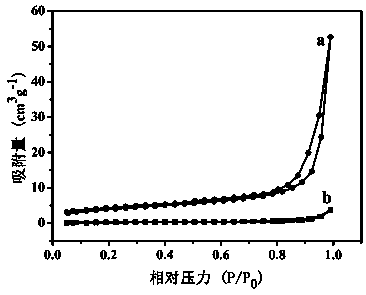

[0031] (1) Using graphite powder as raw material, graphene oxide was synthesized by Hummers method, and then graphene oxide was dispersed in N,N-dimethylformamide solution.

[0032] (2) Add 1.0 mmol cuprous chloride, 1.0 mmol indium chloride, and 2.5 mmol thioacetamide to 40 mL N,N-dimethylformamide solution and stir until the solution is transparent, then add 0.00211 g graphene, Then sonication was performed for 60 min.

[0033] (3) Transfer the solution to a 100 mL reactor, 120 o C, the reaction time is 8 hours.

[0034] (4) Centrifuge the reacted sample and wash it several times with deionized water and ethanol. o C for 12 hours under vacuum. Then take it out, let it cool naturally, and grind it. The obtained product is rGO-CuInS 2 Nanocomposite photocatalysts.

Embodiment 2

[0036] (1) Using graphite powder as raw material, graphene oxide was synthesized by the Hummers method, and then graphene oxide was dispersed in ethylene glycol solution.

[0037] (2) Add 1.0 mmol of cuprous chloride, 1.0 mmol of indium chloride, and 2.5 mmol of thioacetamide into 40 mL of ethylene glycol solution and stir until the solution is transparent, then add 0.00211 g of graphene, and then perform ultrasonication for 60 min .

[0038] (3) Transfer the solution to a 100 mL reactor, 120 o C, the reaction time is 8 hours.

[0039] (4) Centrifuge the reacted sample and wash it several times with deionized water and ethanol. o C for 12 hours under vacuum. Then take it out, let it cool naturally, and grind it. The obtained product is rGO-CuInS 2 Nanocomposite photocatalysts.

Embodiment 3

[0041] (1) Using graphite powder as raw material, graphene oxide was synthesized by Hummers method, and then graphene oxide was dispersed into ethanol solution.

[0042] (2) Add 1.0 mmol of cuprous chloride, 1.0 mmol of indium chloride, and 4 mmol of thioacetamide into 40 mL of ethanol solution and stir until the solution is transparent, then add 0.01055 g of graphene, and then perform ultrasonication for 60 min.

[0043] (3) Transfer the solution to a 100 mL reactor, 180 o C, the reaction time is 15 hours.

[0044] (4) Centrifuge the reacted sample and wash it several times with deionized water and ethanol. o C for 12 hours under vacuum. Then take it out, let it cool naturally, and grind it. The obtained product is rGO-CuInS 2 Nanocomposite photocatalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com