Multi-strand casting machine capable of producing super large broken section beam blank or plate blank and producing method

A technology of multi-strand continuous casting and super large cross-section, applied in the field of continuous casting equipment in the iron and steel metallurgy industry, can solve the problems of low productivity of the special-shaped billet casting machine, easy cracking of the casting billet, singleness, etc., and achieve the effect of improving the productivity of the casting machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

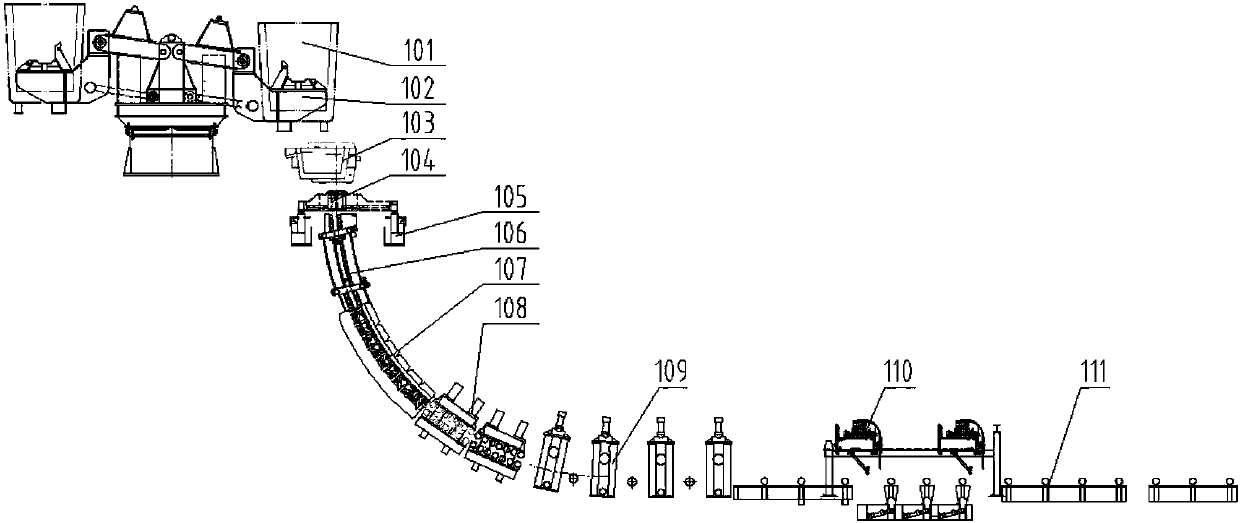

[0033] Embodiment 1: Production of special-shaped blanks with super large cross-sections, or production of slabs with a thickness of ≤200mm

[0034] The maximum section of profiled billet is 1500x500x120mm, the unit weight reaches 2.2t / m, and the minimum section is 350x290x100mm. The slab can be produced with a section of (150~200) x (800~1500) mm. The slab includes: ordinary steel, high-alloy steel with strong crack sensitivity (such as 18MnCr5, 42CrMo4), and pipeline steel X60-X80 (including Nb, V, Ti).

[0035] When producing shaped billets, the ladle 101 is rotated to the pouring position through the rotary table 102, and the molten steel in the ladle 101 is distributed to the shaped billet crystallizers 104 of each flow through the middle ladle 103 (the cooling water of the crystallizers is determined by numerical simulation calculations). The size and position of the hole ensure the reasonable heat transfer of the complex-shaped slab, obtain a uniform slab shell thickne...

Embodiment 2

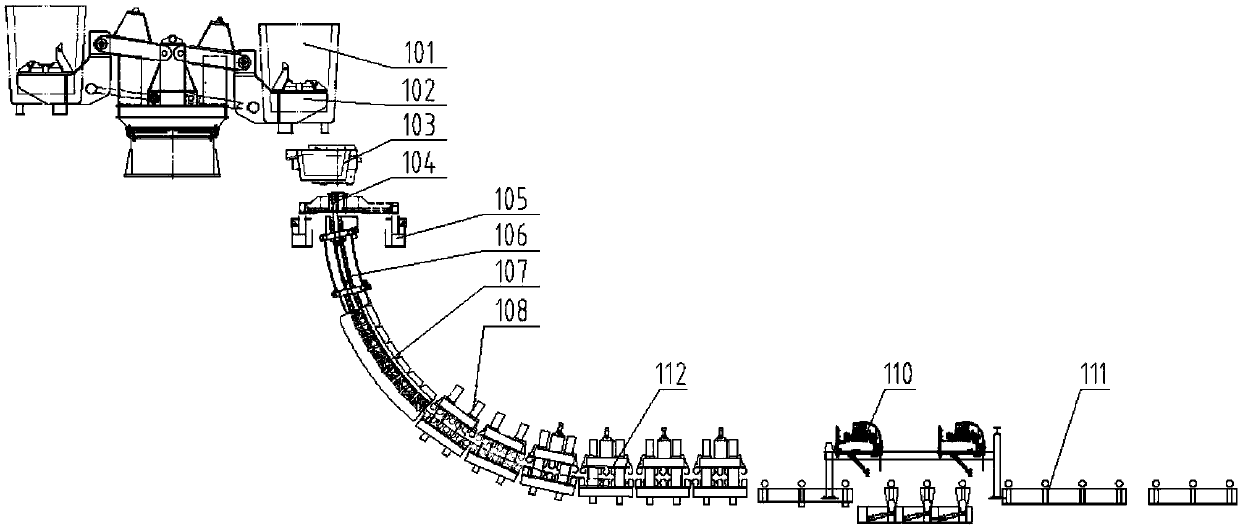

[0038] Embodiment 2: Production of super-large cross-section special-shaped blanks and slabs with a thickness of 200-300mm

[0039] The maximum section of profiled billet is 1500x500x120mm, the unit weight reaches 2.2t / m, and the minimum section is 350x290x100mm. The slab can be produced with a cross-section of (200~300)x(800~1500)mm. If the length of the horizontal section of the tension-leveling unit is increased, the maximum thickness of the slab can reach 350mm. It can also produce high-alloy steel with strong crack sensitivity such as 18MnCr5, 42CrMo4, pipeline steel X60~X80 (including Nb, V, Ti).

[0040] When the thickness of the produced slab exceeds 200mm, since the end point of solidification of the cast slab will move backward, the structure of the billet drawing and car pulling unit at this time should be replaced by a close-packed multi-roller clamping structure similar to the structure of the sector group 108 Tension straightening unit 112. The process of produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com