Continuous multi-layer dryer for plywood and method using same

A dryer and plywood technology, which is applied in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems of inability to meet production needs, reduce production efficiency, low drying efficiency, etc., to improve the degree of automated production and The effect of production efficiency, improving utilization rate and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

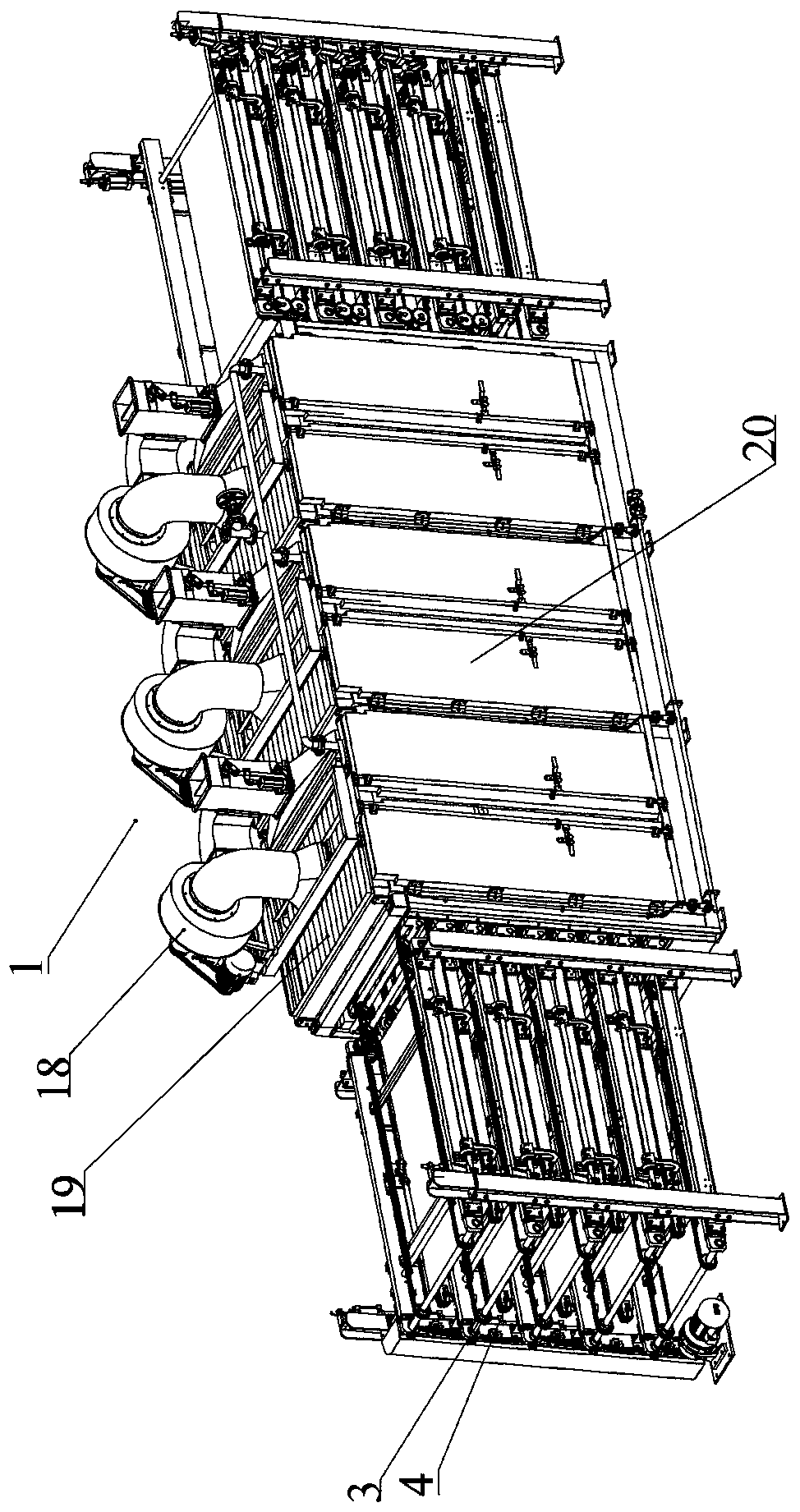

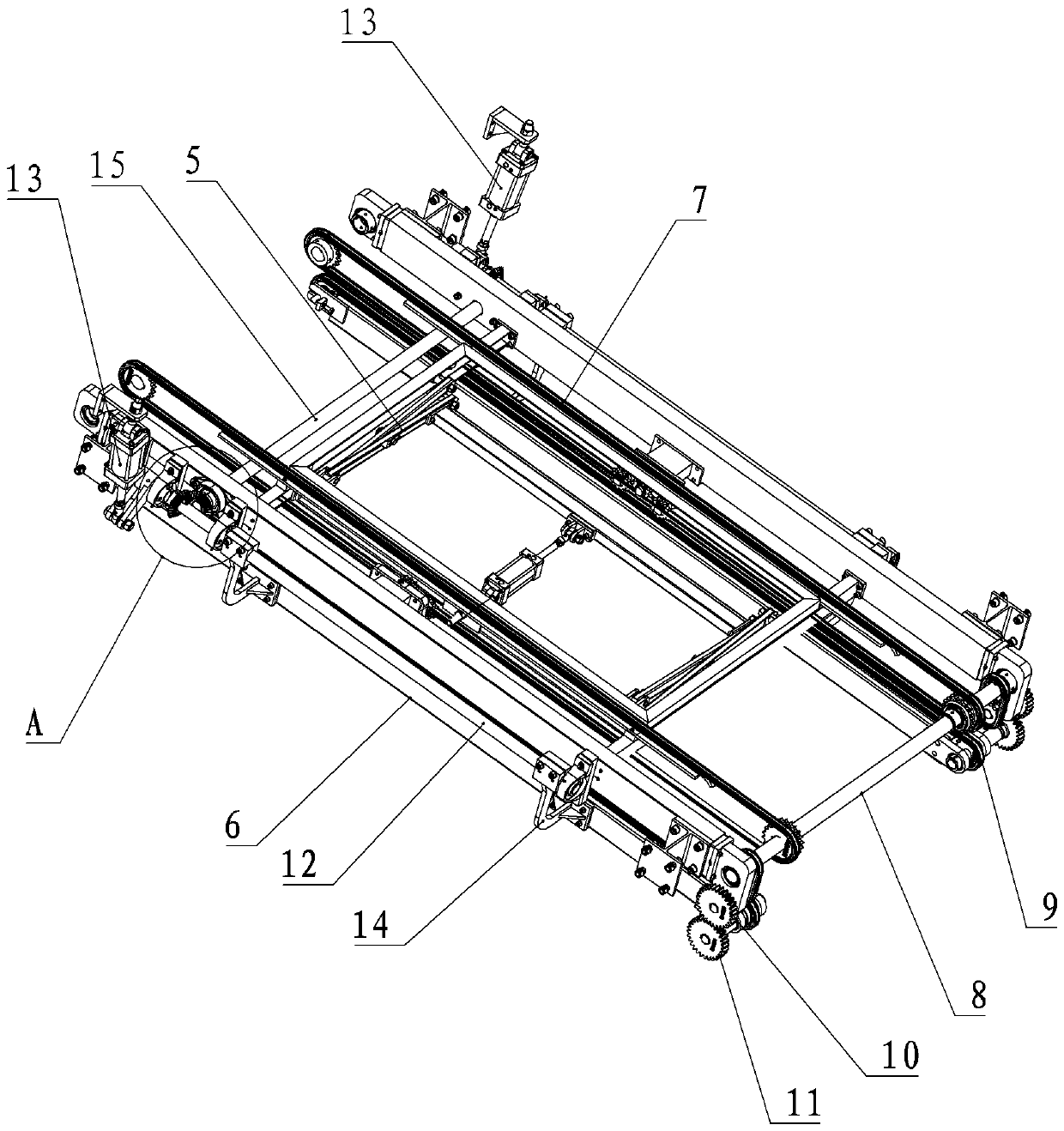

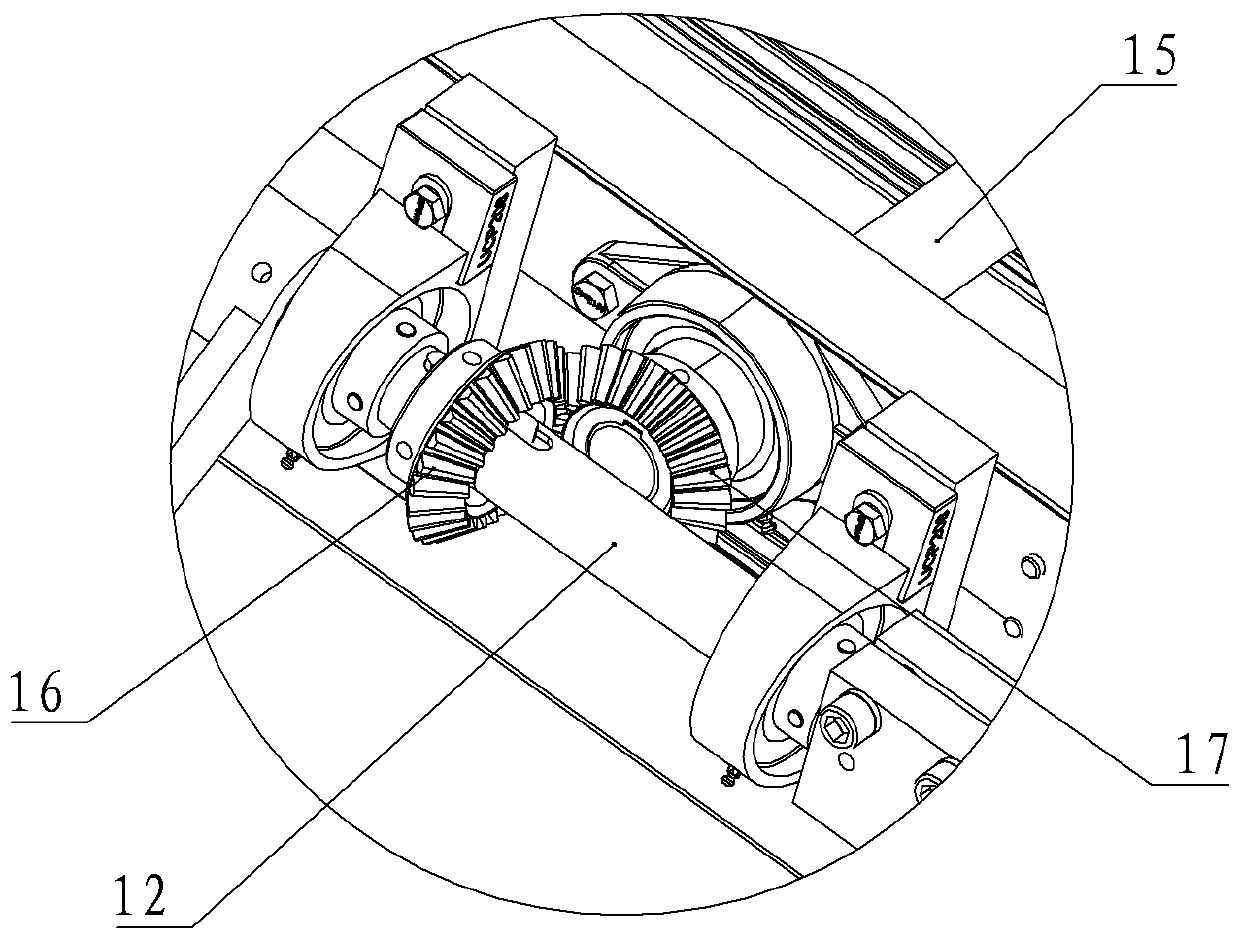

[0023] refer to Figure 1 to Figure 2 , plywood continuous multi-layer drying machine, comprising a dryer 1, a multi-layer translation conveyor belt 2 is provided in the dryer 1, and a lifting conveying mechanism 3 and a clamping mechanism 3 are respectively provided at both ends of the multi-layer translation conveyor belt 2 The conveying mechanism 4, the upper layer of the lifting conveying mechanism 3 is correspondingly provided with a clamping conveying mechanism 4; the lifting conveying mechanism 3 is at least composed of a lifting frame 5 and a driving mechanism of the lifting frame 5, and the driving mechanism drives the lifting frame 5 to the clamping conveying mechanism 4 positions move up and down; the clamping and conveying mechanism 4 is at least composed of a pair of clamping arms 6 that can be opened and closed, and an opening and closing drive mechanism that drives the clamping arms 6 to open and close. By using the lifting conveying mechanism 3 and the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com