A rail integrated structure

A guide rail and body technology, applied in the field of guide rail integrated structure, can solve problems such as degumming and easy deformation of metal pads, pinching and cracking of guide rail glass, loss of pieces and deformation, etc., to improve inspection speed, simplify inspection items, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

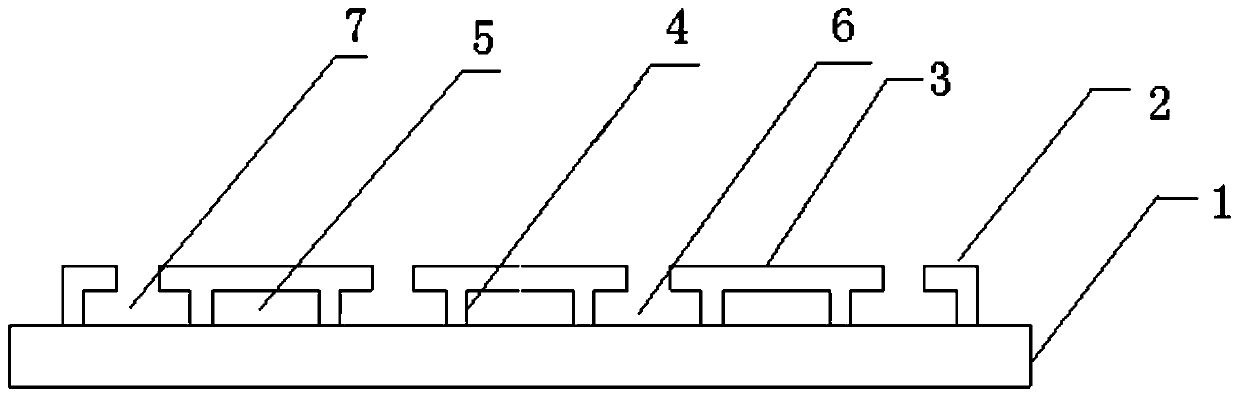

[0014] This embodiment provides a guide rail integrated structure, the structure is as follows figure 1 As shown, including the guide rail body 1, a right-angle steel sheet folding plate 2 is respectively provided near the two ends of the guide rail body, and the right-angle steel sheet folding plate 2 is relatively arranged on the guide rail body 1, between the right-angle steel sheet folding plates 2 at both ends There are a number of steel plates 3 between them, and a connecting steel bar 4 is arranged at both ends near the bottom of each steel plate 3. Each steel plate 3 is fixedly installed on the guide rail body 1 through the connecting steel bar 4. The steel plates 3 and the connecting steel bars 4. The right-angle steel sheet folding plate 2 and the guide rail body 1 form an integrated structure that does not need to be disassembled. Each steel plate 3 forms an upper and lower bar car slot 5 between the connecting steel bars 4 near the bottom ends and the guide rail bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com