Positioning mechanism for continuous code spraying of aluminum plate

A positioning mechanism and coding technology, applied in typewriters, printing, printing devices, etc., can solve problems such as low production efficiency, and achieve the effect of accurate and precise delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] For better understanding and implementation, the present invention will be further described below in conjunction with accompanying drawing:

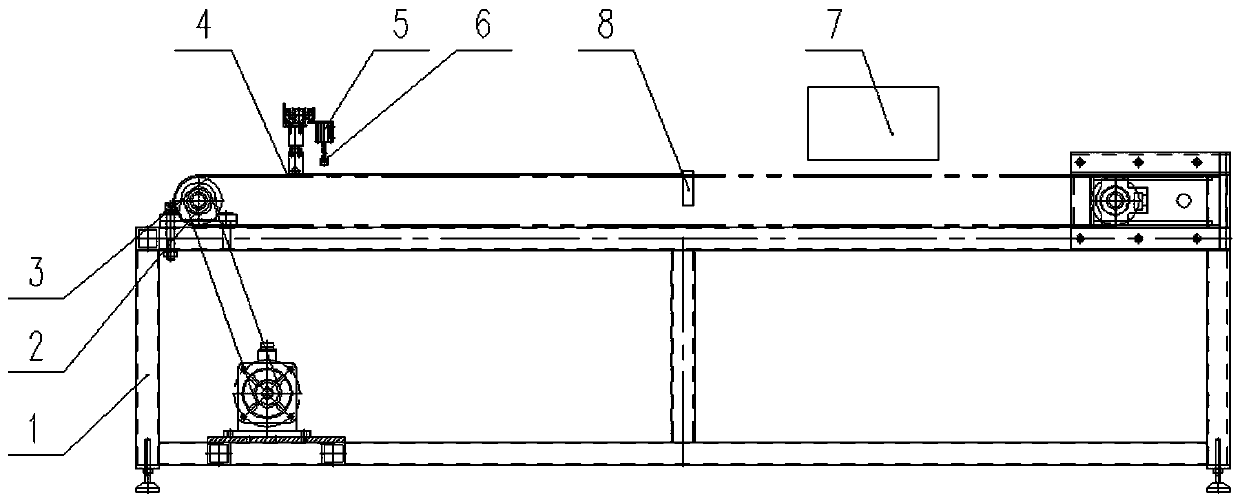

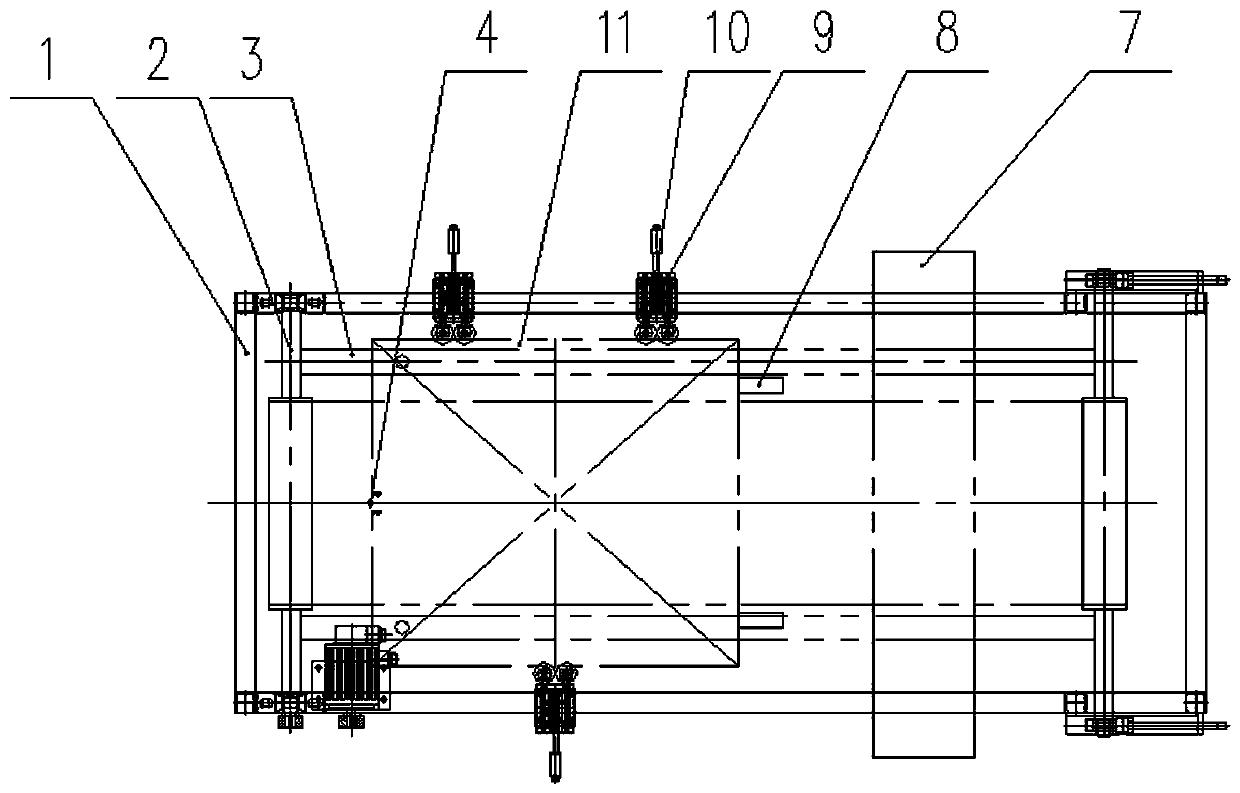

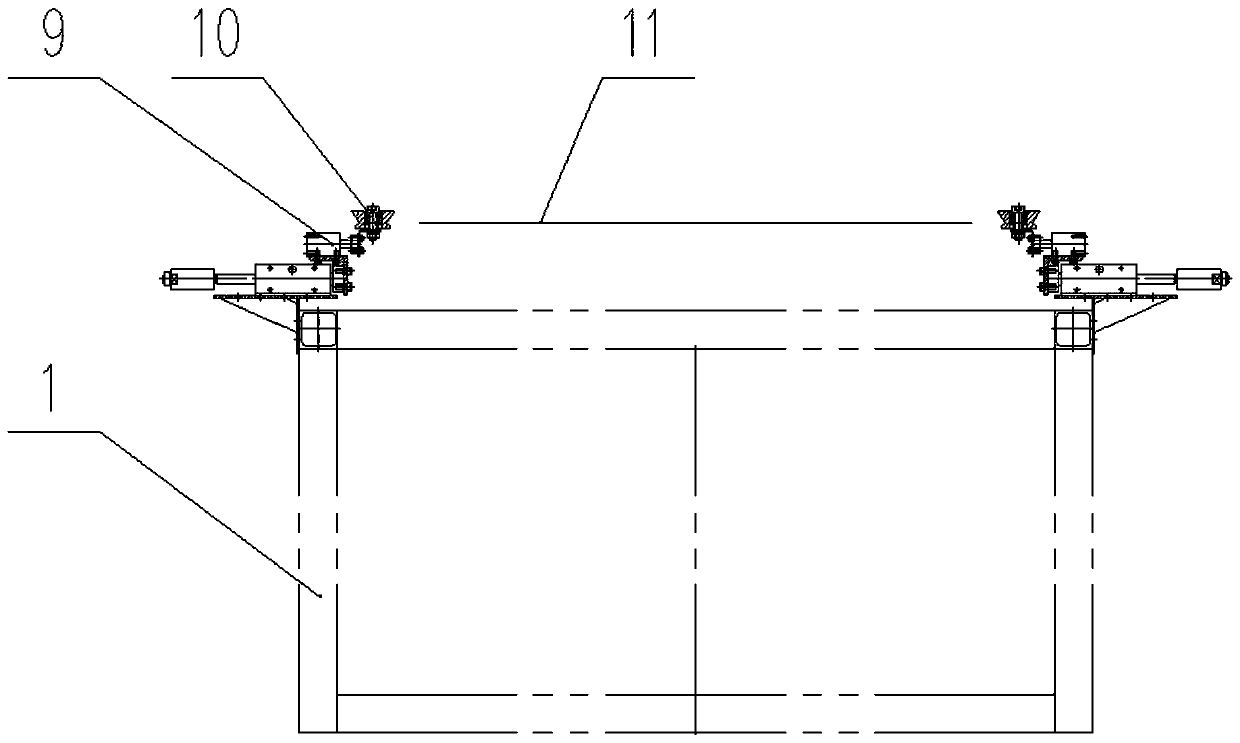

[0012] The positioning mechanism for continuous inkjet printing on aluminum plates includes a frame 1, an inkjet printer 7 is installed on the upper right part of the frame 1, a transmission shaft 2 is arranged on both sides of the frame 1, the transmission shaft 2 is installed on the frame 1, and a printing is arranged between the two transmission shafts 2 The guide belt 3 and the printing guide belt 3 are equipped with equidistant positioning stoppers 4, the positioning stoppers 4 are in the shape of teeth, the gap between the positioning stopper 4 and the printing guide belt 3 is 0.5mm, and the pressure plate cylinder 5 is installed on the printing guide belt 3 tops, the lower end of the pressing plate cylinder 5 is provided with a pressing plate 6, and both sides of the frame 1 are provided with side positioning cylinders 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com