Permanent magnetic suspension vibration reducing and noise lowering device for train compartment

A technology of vibration reduction and noise reduction and magnetic suspension, applied in the direction of the device that moves laterally between the underframe and the bogie, can solve problems such as vibration and noise, car body structure, passenger hazards of track structure, vibration and noise aggravation, etc. Achieve the effects of reducing vibration and noise, easy implementation, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

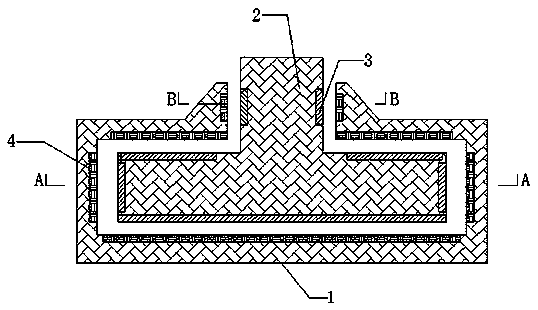

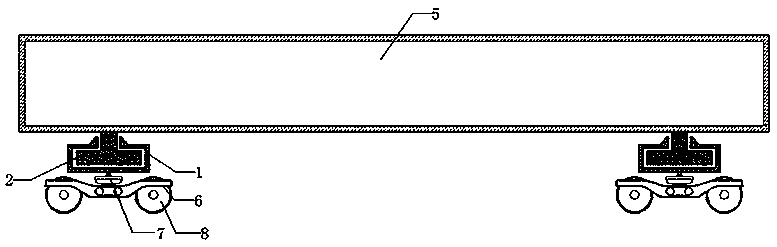

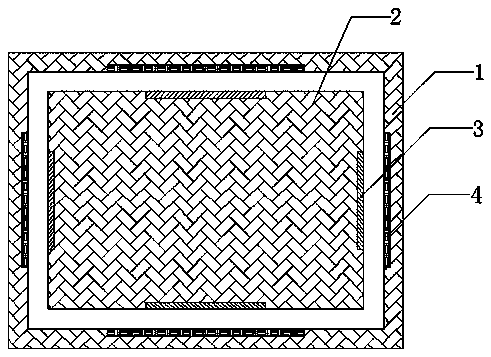

[0020] Example: such as figure 1 As shown, the permanent magnetic suspension vibration damping and noise reduction device of the train car in this embodiment is composed of a suspension box 1 and a suspension car base 2. The internal cavity section of the suspension box 1 is as follows figure 1 It is shown in an inverted T shape, and a number of second magnets 4 are provided on the inner wall of the suspension box 1. The shape and size of the suspension car base 2 match the shape and size of the inner cavity of the suspension box 1, that is, its shape is also an inverted T shape, and its size is slightly smaller than the inner cavity of the suspension box 1. A number of first magnets 3 are provided on the surface of the suspension car base 2, and the positions of the first magnets 3 correspond to the positions of the second magnets 4 in the suspension box 1. The same magnetic poles of the first magnet 3 and the second magnet 4 are opposed to each other, and the magnetic repulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com