Biomass indirect liquefaction to synthetic oil process and system

A biomass and synthetic oil technology, applied in the petroleum industry, hydroprocessing process, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of single, no circulation of Fischer-Tropsch synthesis tail gas, low conversion rate of Fischer-Tropsch synthesis process, etc., to achieve The effect of simplifying the process flow, eliminating the conversion process, and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

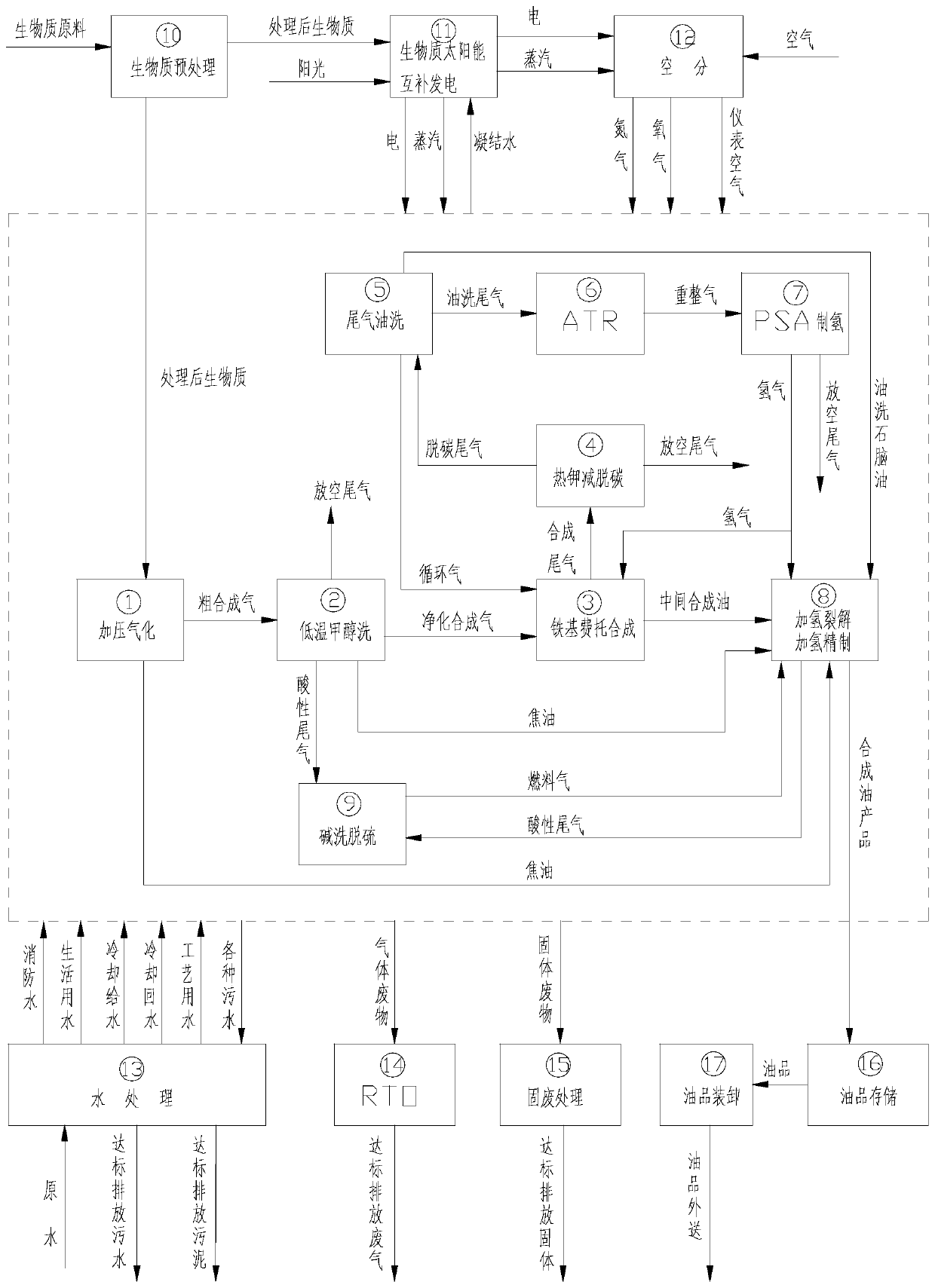

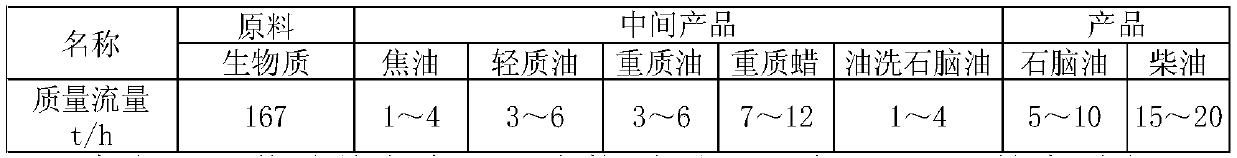

[0063] Such as figure 2 As shown, taking the synthetic oil product technological process with an annual output of 200,000 tons as an example, the technological process of the specific method is as follows (①~ )ongoing:

[0064] In this embodiment, biomass is used as raw material, and the property data of biomass raw material are shown in Table 3 below.

[0065] table 3

[0066] unit value net calorific value MJ / kg 18.5-20(dry) moisture content % 10-35 Bulk density Kg / loose m 3

[0067] Through the biomass pretreatment unit, the raw material is processed into a block size of 20-60mm, 20-60mm wide, and 10-20mm thick, dried to 15%-35wt%, and sent to pressurized gasification at a rate of 167t / h The unit performs biomass gasification to obtain 175.67t / h crude synthesis gas and 3.04t / h tar. The composition of crude synthesis gas is shown in Table 4.

[0068] Table 4

[0069] composition H 2

[0070] The crude synthesis gas pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com