Hydraulic control system and hinge dam assembly

A hydraulic control system and hinge dam technology, applied in the field of movable dams, can solve problems such as easy to get stuck in floating objects, high flow rate, and unable to control the synchronous action of hydraulic cylinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

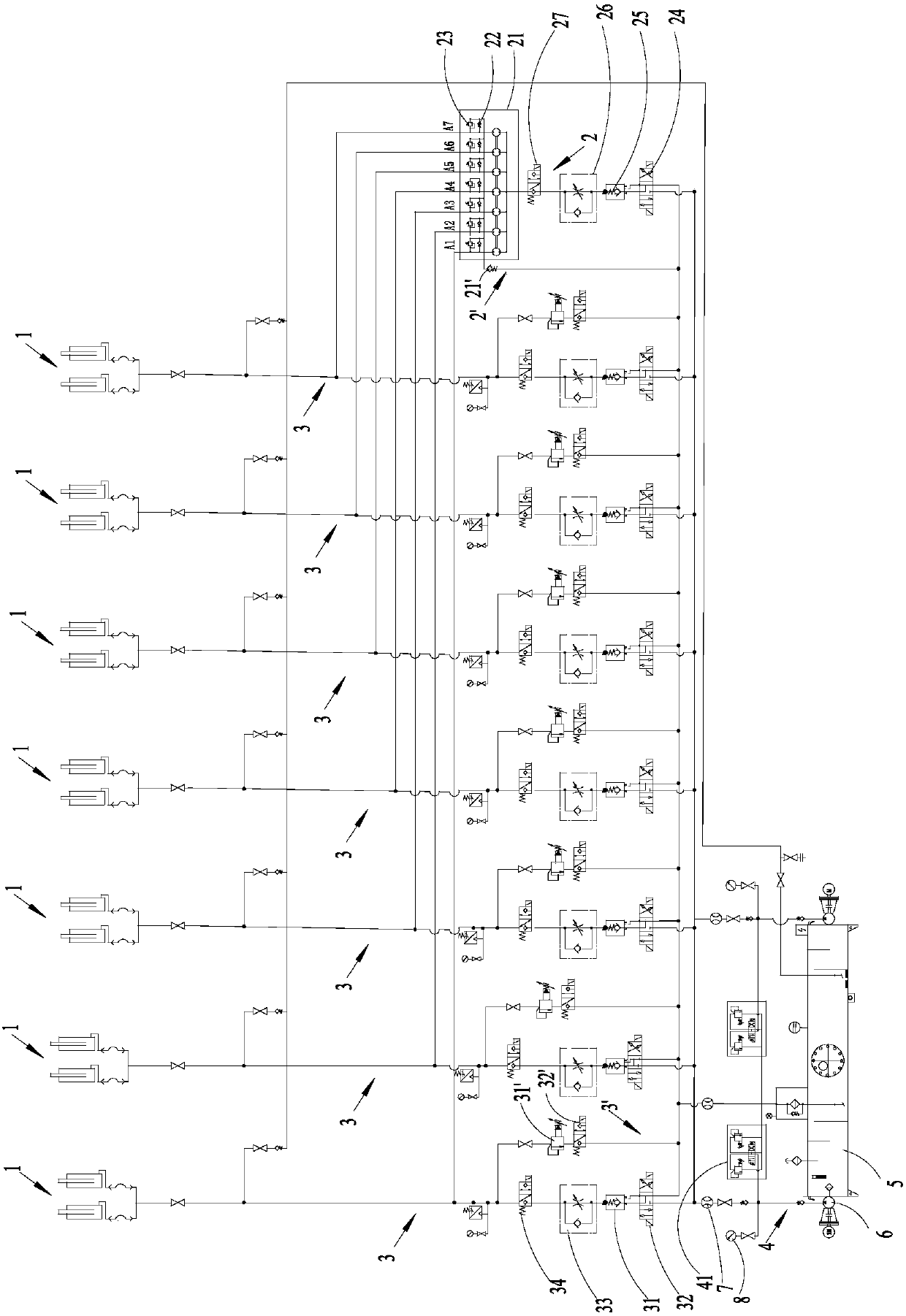

[0059] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0060] The application provides a hydraulic control system, which is used to control the lifting of multi-leaf hinge dams. Hinge dams are usually used to intercept river courses. When the hinge dams are opened, the river course is unblocked; Can store water.

[0061] Specifically, such as figure 1 As shown, the hydraulic control system includes a plurality of hydraulic cylinders 1. Usually, one hydraulic cylinder 1 controls one hinge dam to drive the hinge dam to go up and down. Of course, in order to ensure the reliable lifting of the hinge dam, a scheme of jointly driving a hinge dam to lift by multiple hydraulic cylinders 1 can also be adopted.

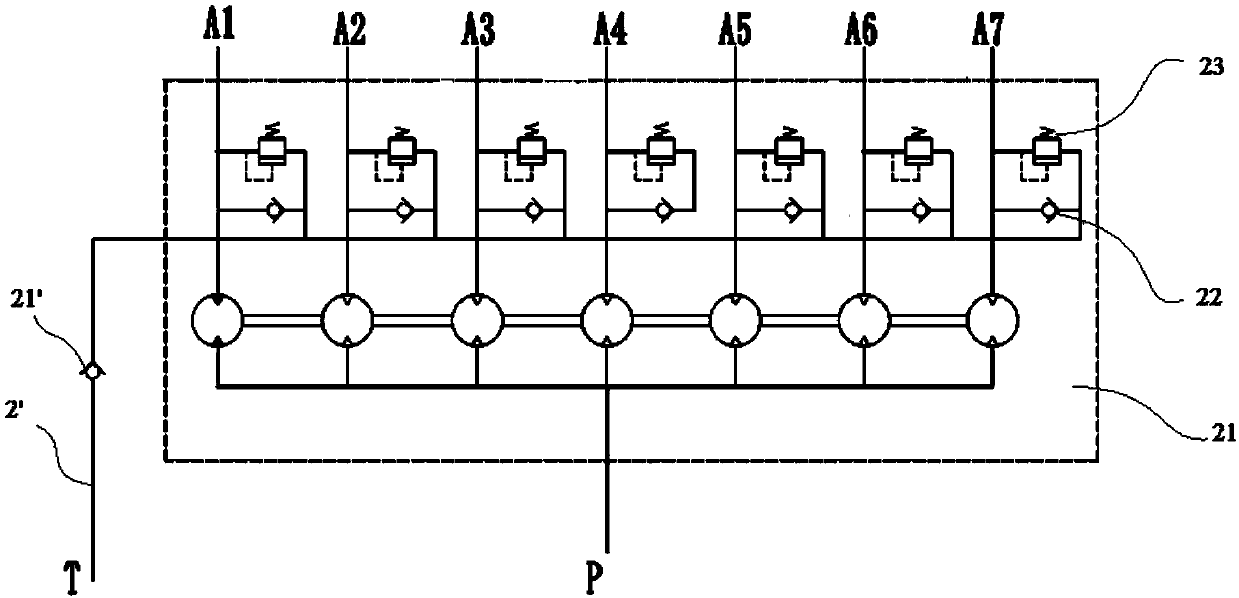

[0062] The hydraulic control system also includes a first branch 2 that controls the synchronous actions of the hydraulic cylinders 1. The first branch 2 includes a diversion s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com