An intelligent weighing sensor overload protection debugging system and debugging method thereof

A weighing sensor and overload protection technology, which is applied in the control/regulation system, general control system, detailed information of weighing equipment, etc., can solve the problems of low debugging accuracy, low work efficiency, and affecting test accuracy, etc., to achieve The effect of high test efficiency, convenient repeat test and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

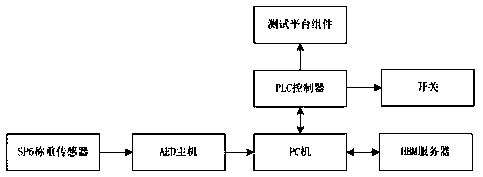

[0025] A kind of intelligent weighing sensor overload protection debugging system of the present embodiment includes

[0026] Test bench components: realize the automatic loading and unloading experiments of the sensors to be tested;

[0027] AED host: record the force sensitivity of the sensor to be tested;

[0028] Test PC: control the loading and unloading of weights, and use the test system to judge the sensitivity data obtained;

[0029] Dedicated server: Provide real-time data exchange and storage for detection data.

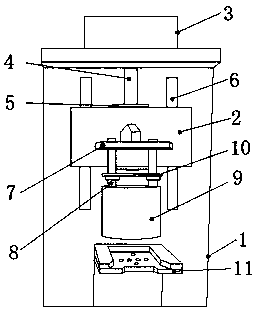

[0030] The test bench assembly includes a test bench 11, a weight lifting device, a first weight 9, a second weight 10, a PLC controller, and a control switch. The weight lifting assembly includes a drive motor and a lifting assembly, and the weights are in order from top to bottom. Hanging in series on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com