Test device, test method and prediction method for tangential dynamic characteristics of bolted joint

A technology of bolted joints and dynamic characteristics, applied in the testing of machine/structural components, measuring devices, testing of mechanical components, etc. replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

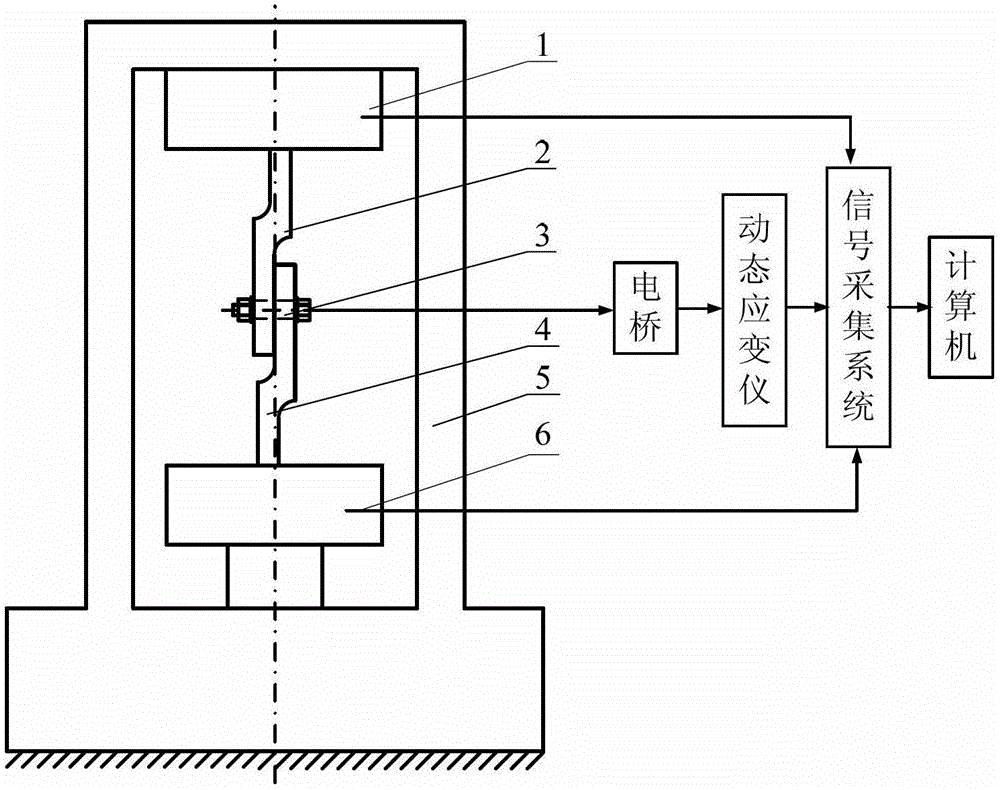

[0035] The device for predicting the tangential dynamic characteristics of the bolt group of the present invention will be further described in detail below in conjunction with the working principle and the structural drawings.

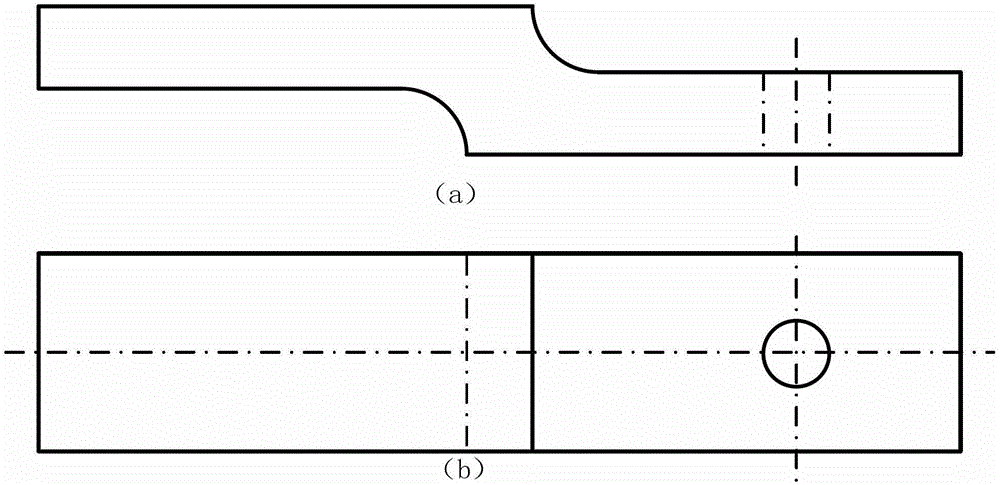

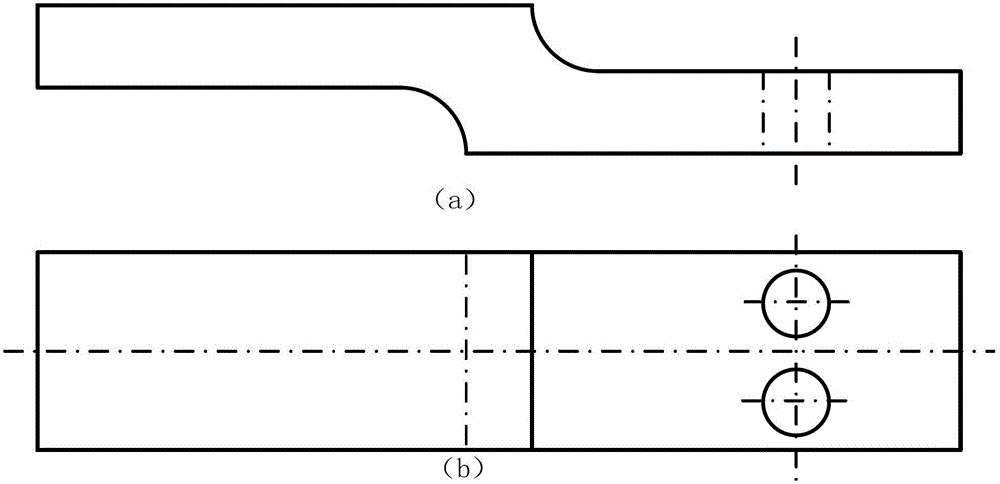

[0036] Such as Figure 1 to Figure 9 As shown in (b), a device for predicting the tangential dynamic characteristics of a bolt group structure, including a tensile testing machine 5, an upper specimen 2, a lower specimen 4, high-strength bolts 3, strain gauges, bridges, dynamic strain instrument, signal acquisition system and computer. Utilize a torque wrench to fix the upper fixture 1 of the upper specimen 2 and the tensile testing machine 5, and fix the lower specimen 4 and the lower clamp 6 of the tensile testing machine 5; To ensure the coaxiality, first clamp the lower test piece 4, after adjusting the upper fixture 1 of the tensile testing machine 5, clamp the upper test piece 2; along the center of the screw axis of the bolt 3, a Strain gauge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com