Two-phase pipeline window, measurement system, view acquisition method, 3D reconstruction method and cavitation rate measurement

A pipeline and viewing window technology is applied in the fields of two-phase pipeline viewing windows, measurement systems, view acquisition, three-dimensional reconstruction and cavitation rate measurement. Less, eliminate the effect of image distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

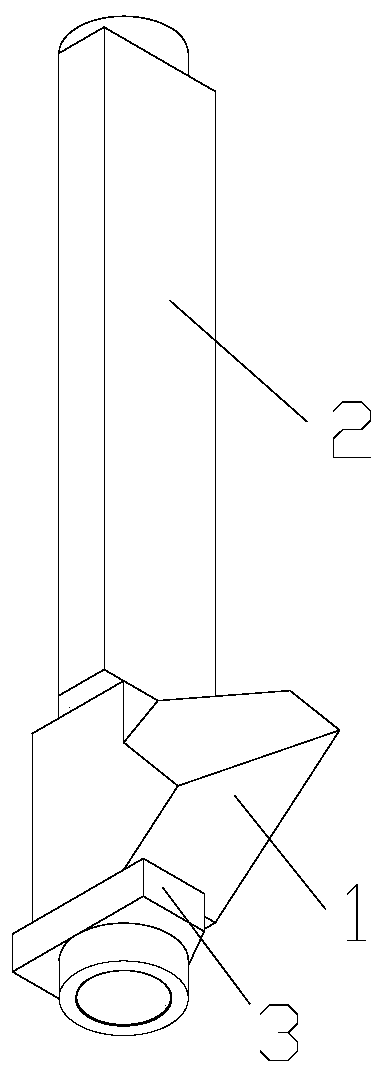

[0065] A kind of two-phase fluid flow described in the present invention can observe simultaneously shape and measurement systems for gas-liquid distribution in cross-sections of fluids include:

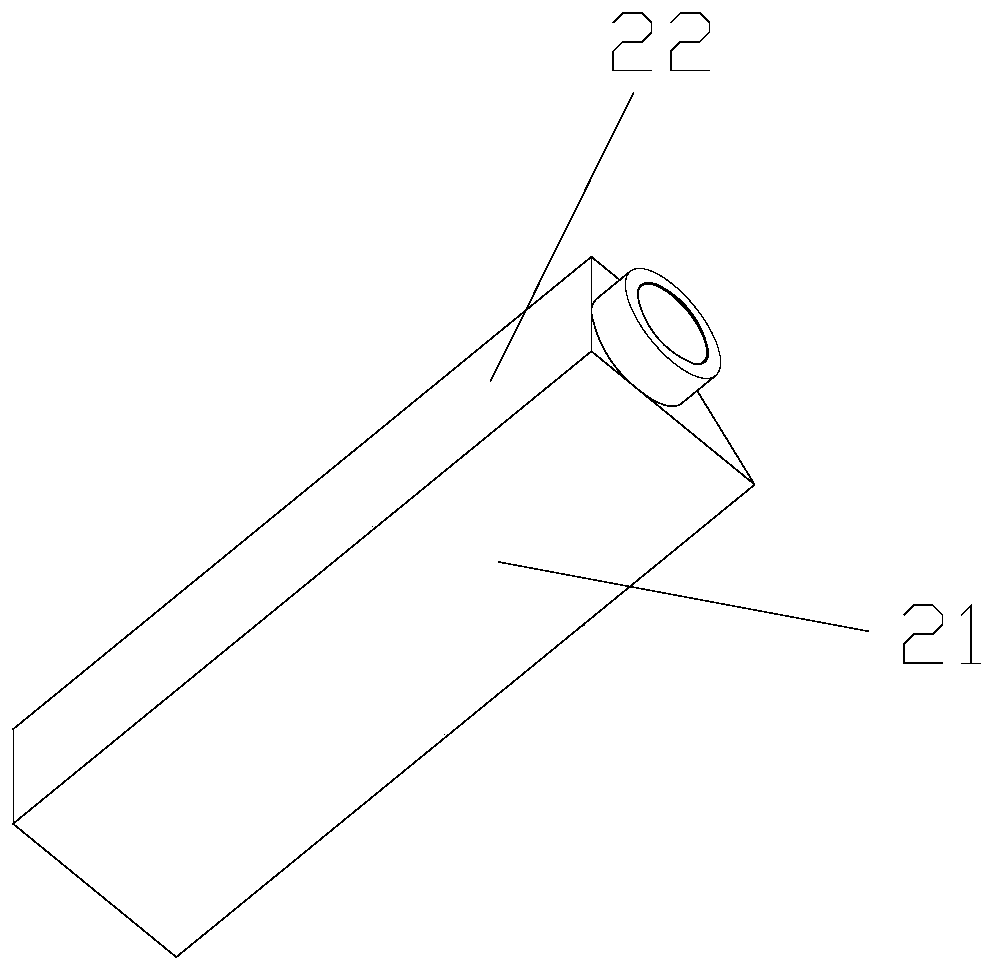

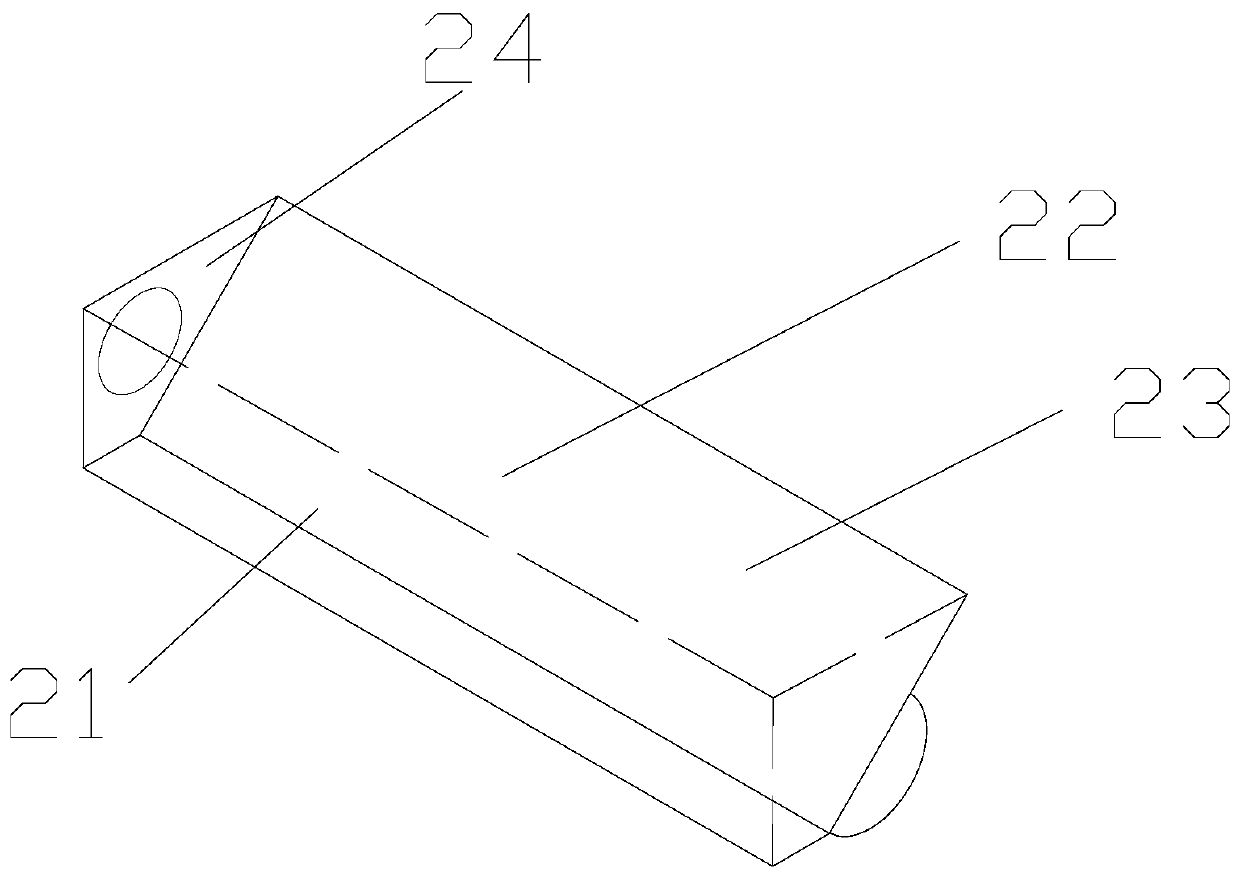

[0066] A measurement system capable of simultaneously observing two-phase fluid manifolds and fluid cross-section gas-liquid distribution, including the pipeline window of the present invention; and a high-speed camera for photographing the cross-sectional observation surface 11 and the side observation surface 21 of the pipeline window , an in-line 532nm laser for irradiating laser light into the pipe window; a visible light surface light source for providing surface light to illuminate the surface light source plane 22

[0067] The inline 532nm laser irradiates the section of the working medium flowing through the window of the pipeline to excite the fluorescent indicator in the working medium.

[0068] A high-speed camera captures side views of the working fluid in two different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com