Film lens and preparation process thereof

A thin-film lens and polyester film layer technology, which is applied in the fields of lenses, optics, instruments, etc., can solve the problems of poor product consistency, easy deformation, and long production cycle, so as to reduce production costs and labor costs, and shorten the production process Cycle time and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

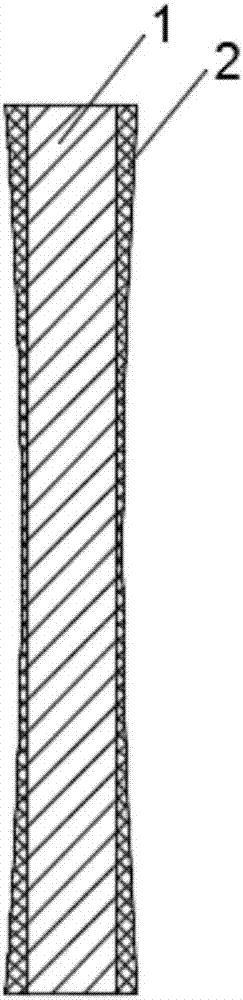

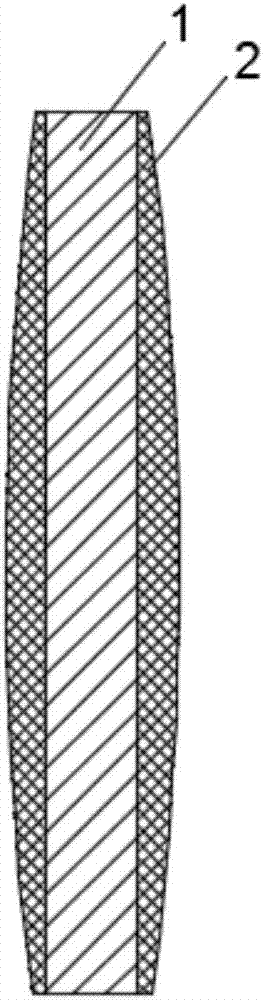

[0053] Take the polyester film layer 1 that two layers of polystyrene resin with a thickness of 0.01 mm and polycarbonate (PC) with a thickness of 0.005 mm are copolymerized. After the surface is cleaned of dirt, the leveling degree of the polyester film layer 1 is 0.001mm, transparency ≥ 99.99%, transmittance ≥ 99.99%; high-voltage electrostatic adsorption is used for dust removal; the polyester film layer 1 after dust removal, under high-voltage electrostatic conditions, uses corona to remove the oxide layer;

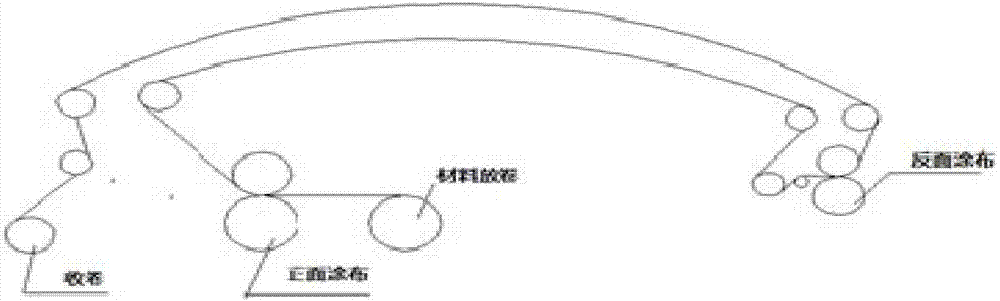

[0054] Get transparency ≥ 99.99%, light transmittance ≥ 99.99% high transparent polymer coating 2, double-sided spin coating on the surface of the polyester film layer 1 after removing the oxide layer (such as image 3 shown in the coating process); use 100 ° C hot air curing for 10 seconds; cut and carry out optical inspection after the quality is qualified, the film lens of the present invention is obtained.

Embodiment 2

[0056] Take the polyester film layer 1 that two layers of polystyrene resin with a thickness of 0.01 mm and polycarbonate (PC) with a thickness of 0.005 mm are copolymerized. After the surface is cleaned of dirt, the leveling degree of the polyester film layer 1 is 0.001mm, transparency ≥ 99.99%, transmittance ≥ 99.99%; high-voltage electrostatic adsorption is used for dust removal; the polyester film layer 1 after dust removal, under high-voltage electrostatic conditions, uses corona to remove the oxide layer;

[0057] Take 15 parts of ethyl acetate, 5 parts of one-component anaerobic adhesive (trimethylene glycol dimethacrylate), 15 parts of polystyrene resin, 3 parts of one-component anaerobic adhesive curing agent (tertiary amine : saccharin is 1:1), 30 parts of reactive diluent (ethyl acetate), 10 parts of oligomer (polyurea with number average molecular weight less than 10000), 8 parts of photoinitiator (α-hydroxyalkyl phenone), Highly transparent polymer coating 2 compo...

Embodiment 3

[0059] Take the polyester film layer 1 that two layers of polystyrene resin with a thickness of 0.01mm and polycarbonate (PC) with a thickness of 0.005mm are copolymerized. After the surface is cleaned of dirt, the leveling degree of the polyester film layer 1 is 0.001mm, transparency ≥ 99.99%, transmittance ≥ 99.99%; high-voltage electrostatic adsorption is used for dust removal; the polyester film layer 1 after dust removal, under high-voltage electrostatic conditions, uses corona to remove the oxide layer;

[0060]Take 11 parts of ethyl acetate, 4 parts of one-component anaerobic adhesive (trimethylene glycol dimethacrylate), 17 parts of polystyrene resin, 3 parts of one-component anaerobic adhesive curing agent (tertiary amine : Saccharin is 1:1), 22 parts of reactive diluent (ethyl acetate), 8 parts of oligomer (polyurea with number average molecular weight less than 10000), 2 parts of defoamer (polyether silicone oil), 7 parts of lubricant (silicone oil), 5 parts of surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com