Preparation method of glue impregnated fiber capacitor type dry bushing capacitor plate material

A capacitor plate and dry-type bushing technology, which is applied to equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, circuits, etc., can solve the problem of insufficient withstand voltage, easy formation of air gaps, and dielectric loss of bushings Partial discharge and other problems, to achieve the effect of improving the manufacturing pass rate, improving electrical performance, and reducing the production process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment, the preparation of gel-impregnated fiber capacitive type dry bushing capacitive plate material

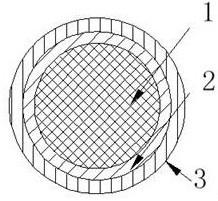

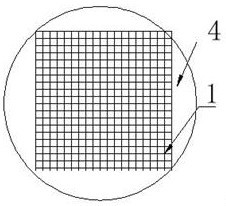

[0023] 1). Synthetic fibers are nylon, polypropylene and polytetrafluoroethylene to obtain millimeter-scale synthetic fiber monofilaments 1 (such as figure 1 As shown), weave fiber mesh cloth 4 with millimeter-level monofilaments with a diameter of 0.10-0.2 mm (such as figure 2 shown).

[0024] 2). After degreasing and roughening the surface of the grid cloth, the transition metal layer I pure copper T2 is electroplated on its surface with a thickness of 5 μm. The transition metal layer I (such as figure 1 The shown 2-transition metal layer Ⅰ) has similar surface potential energy to the monofilament fiber of this type of insulating material to form a firm and not easy to fall off electroplating layer; it has a certain toughness and has the same expansion as the insulating material used in the insulating layer coefficient, and the insulating material used for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com