Method for improving production qualification rate of dry-type bushing

A technology for producing qualified, dry-type bushings, which is applied in the direction of lead-in/through-type insulators, insulators, electrical components, etc. The problems of flatness, concentricity and poor bonding performance can improve the product qualification rate and electrical performance, reduce the production process cycle, and eliminate the curing internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

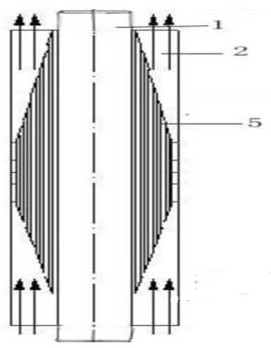

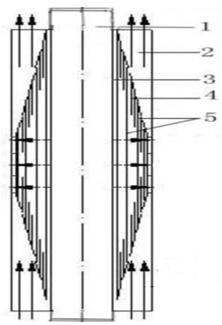

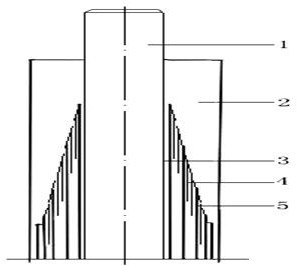

[0024] Such as figure 2 , image 3 Shown is a schematic diagram of the new structure of the zero-layer plate + long and short plates alternately arranged. Long and short pole plates are alternately arranged in the direction of the outer peripheral axis of the dry casing, and the epoxy resin glue flows longitudinally and laterally between the synthetic fiber meshes; finally, a glue-impregnated fiber capacitive dry casing is obtained to improve the dry type. Casing production qualification rate; the specific steps are as follows:

[0025] Step 1, cleaning the conductive rod or mold core rod;

[0026] Step 2, first arrange the zero-potential electrode 3 that penetrates completely in the axial direction on the outer peripheral surface close to the conductive rod 1;

[0027] Step 3, wrapping a layer of synthetic fiber woven mesh cloth 2 on the outer peripheral surface of the zero-potential electrode 3, and then arranging the first layer of long pole plates 5 that completely pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com