Reflective back protection sheet for solar cells

A solar cell, backside protection technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of protecting photovoltaic cells, failure to maintain photovoltaic functions, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

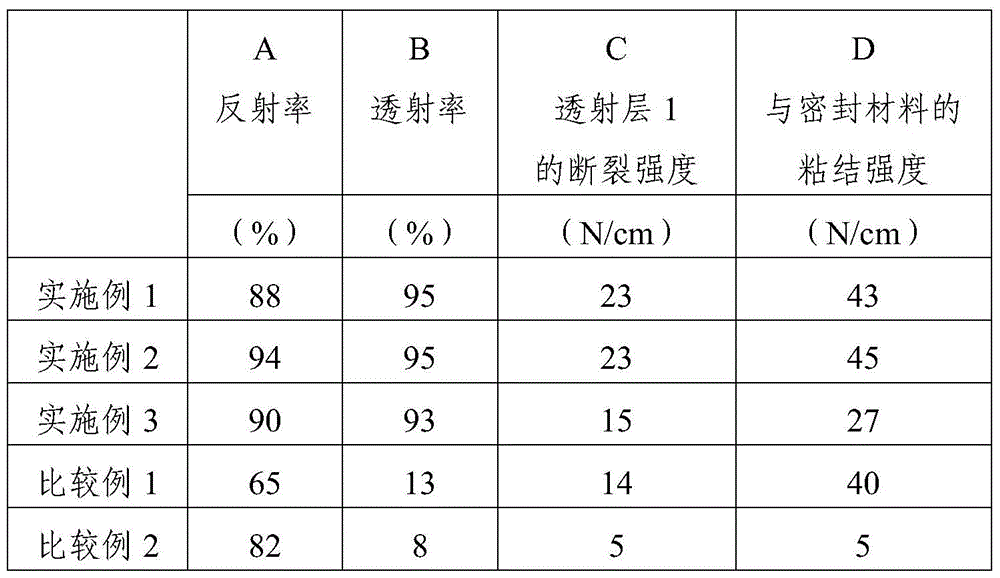

Embodiment 1

[0065] The back protection sheet for solar cells used for the solar cell module was produced as follows.

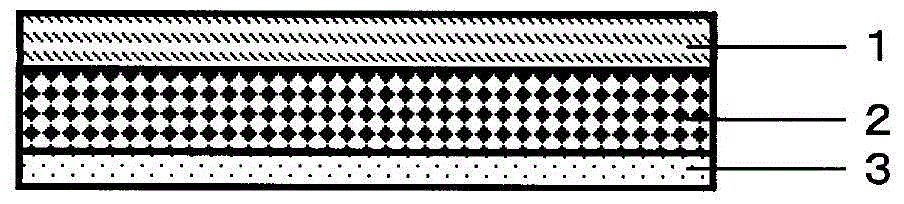

[0066] A back protection sheet was produced, and as its structure, a transmissive layer 1 , a reflective layer 2 , and a protective layer 3 were laminated in this order.

[0067] First, as the reflective layer 2, polyethylene terephthalate resin was mixed with 15 parts of titanium oxide in 100 parts of polyethylene terephthalate resin, and the film was formed by a resin extrusion method using a normal T-die with a thickness of 250 μm. Ethylene diformate film A (PET film).

[0068] Next, as the protective layer 3 , on the surface of the PET film A, a 38 μm Tedlar film (polyvinyl fluoride resin) manufactured by DuPont was bonded by a dry lamination method using a polyurethane adhesive.

[0069] Next, as the transmissive layer 1, on the opposite side of the PET film A, a 50 μm density of 0.94 g / cm was bonded by a dry lamination method using a polyurethane-based adhesive. 3...

Embodiment 2

[0072] As the reflection layer 2, 10 parts of barium sulfate was mixed with 100 parts of polyethylene terephthalate resin, and the thickness of 250 μm polyethylene terephthalate film was formed by the resin extrusion method using a common T-die. The glycol ester film A was prepared in the same manner as in Example 1 except for the above, to produce a back protection sheet for a solar cell, and to laminate a sealing material on the outer surface of the transmissive layer 1 .

Embodiment 3

[0074] Except that the ethylene vinyl acetate copolymer film SB-3 manufactured by TAMAPOLY (タマポリ) Co., Ltd. with a thickness of 50 μm was used as the transmission layer 1, a back protective sheet for solar cells was produced in the same manner as in Example 1. The outer surface is laminated with sealing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com