Multi-partial loading fully-transparent pressure chamber

A pressure chamber, transparent technology used in the application of stable tension/pressure to test the strength of materials, analyze materials, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

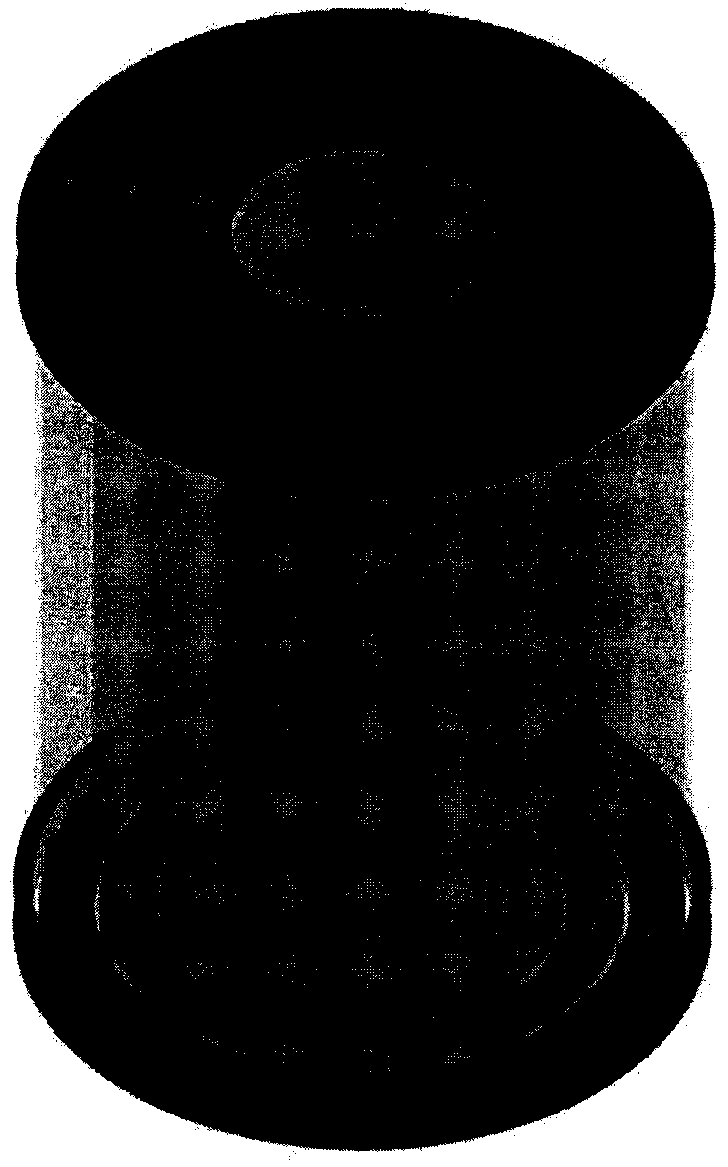

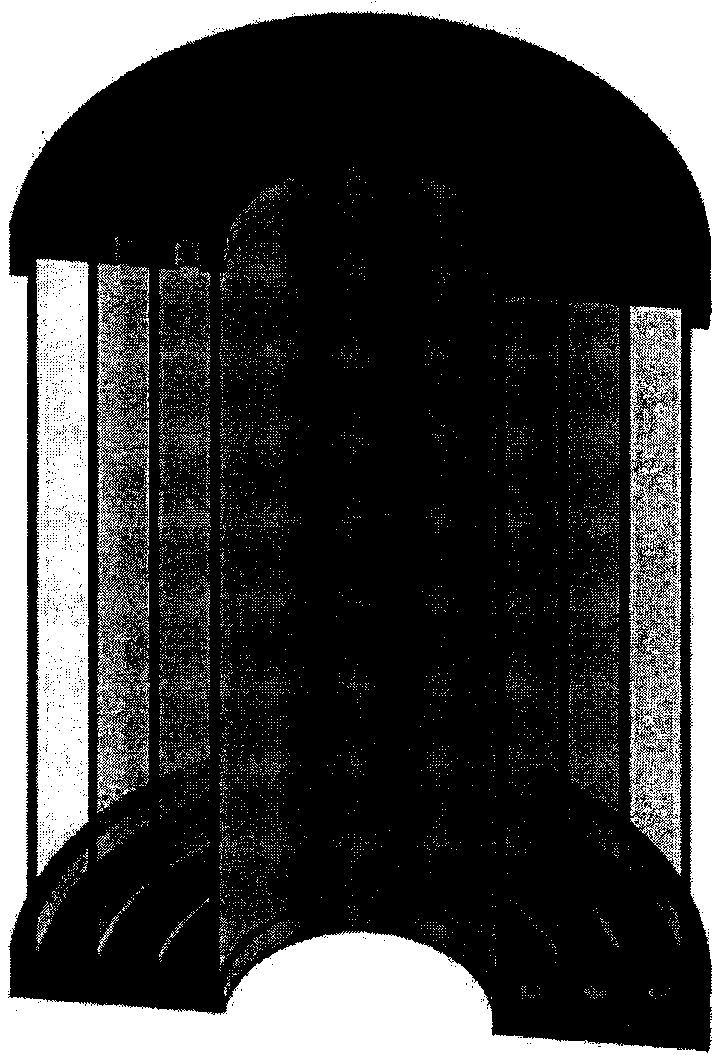

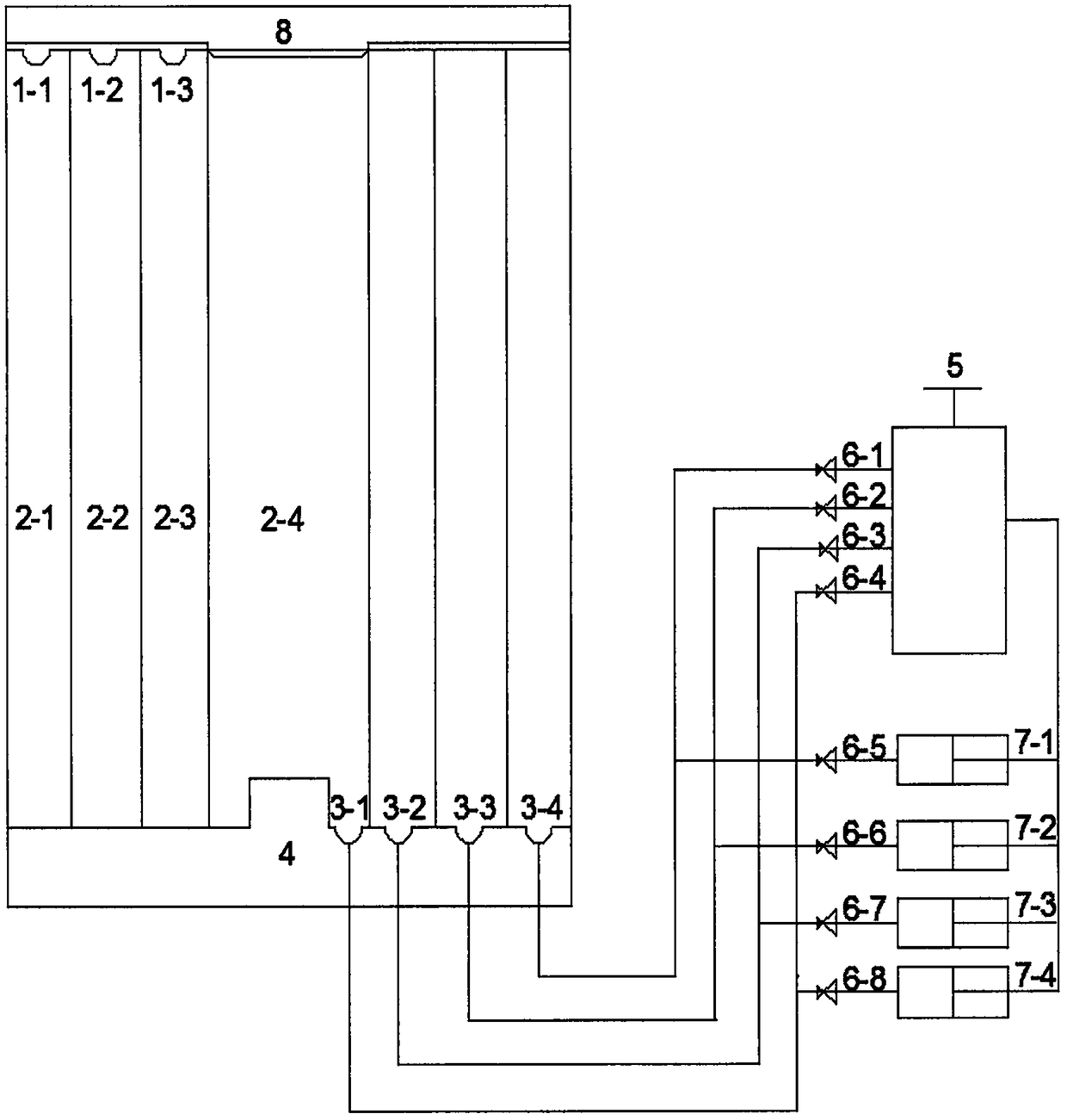

[0017] The fully transparent pressure chamber with multiple load sharing consists of the first pressure chamber cavity 2-1, the second pressure chamber cavity 2-2, the third pressure chamber cavity 2-3, the fourth pressure chamber cavity 2-4, and the bearing platform 4 , supercharger 7, and pressure source 5; four sets of fully transparent hollow cylinders are sealed and matched with the threaded grooves of the bearing platform 4 from inside to outside according to the diameter to form the first pressure chamber cavity 2-1 and the second pressure chamber cavity 2-1. Chamber cavity 2-2, third pressure chamber cavity 2-3, fourth pressure chamber cavity 2-4, sensor control system 8 is installed on the top of the overall pressure chamber, first inlet 3-1, second inlet 3-2, The third inlet 3-3, the fourth inlet 3-4 are connected with the supercharger 7 and the pressure source 5 with pipelines, and the first control valve 6-1, the second control valve 6-2, the third control valve 6-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com