A kind of preparation method and battery of full back contact IBC battery based on laser diffusion

A technology of full back contact and laser diffusion, applied in the field of solar cells, can solve the problems of complex preparation process of IBC cells, unsuitable for low-cost mass production, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

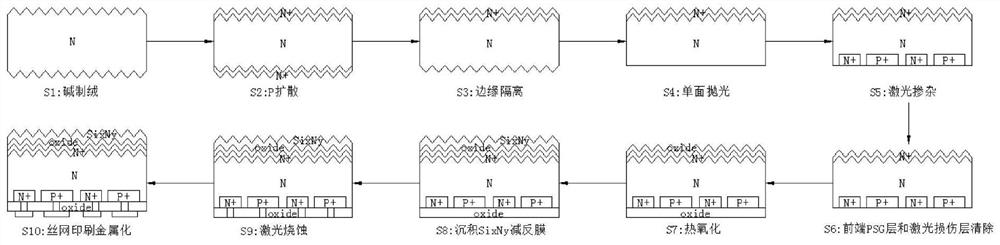

[0037] Such as figure 1 As shown, this embodiment provides a method for preparing a full back contact IBC battery based on laser diffusion, comprising the following steps:

[0038] S1: Alkali texturing: select an N-type monocrystalline silicon wafer, and use hot alkali to make texturing on both sides, so that the front and back of the N-type monocrystalline silicon wafer form a textured layer;

[0039] S2: P diffusion: double-sided or single-sided P diffusion of N-type single crystal silicon wafers with phosphorus source to form FSF on the front side of N-type single crystal silicon wafers;

[0040] S3: Edge isolation: Use a mixed solution of HF and HN03 to remove the back and edge junctions of the N-type single crystal silicon wafer, and only keep the front diffusion layer and the PSG layer above the diffusion layer as the next step of single-side polishing mask;

[0041] S4: Single-side polishing: polishing the back of the N-type monocrystalline silicon wafer with NaOH wit...

Embodiment 2

[0058] Such as figure 1 As shown, this embodiment provides a method for preparing a full back contact IBC battery based on laser diffusion, comprising the following steps:

[0059] S1: Alkali texturing: select an N-type monocrystalline silicon wafer, and use hot alkali to make texturing on both sides, so that the front and back of the N-type monocrystalline silicon wafer form a textured layer;

[0060] S2: P diffusion: double-sided or single-sided P diffusion of N-type single crystal silicon wafers with phosphorus source to form FSF on the front side of N-type single crystal silicon wafers;

[0061] S3: Edge isolation: Use a mixed solution of HF and HN03 to remove the back and edge junctions of the N-type single crystal silicon wafer, and only keep the front diffusion layer and the PSG layer above the diffusion layer as the next step of single-side polishing mask;

[0062] S4: Single-side polishing: polishing the back of the N-type monocrystalline silicon wafer with NaOH wit...

Embodiment 3

[0079] Such as figure 1 As shown, this embodiment provides a method for preparing a full back contact IBC battery based on laser diffusion, comprising the following steps:

[0080] S1: Alkali texturing: select an N-type monocrystalline silicon wafer, and use hot alkali to make texturing on both sides, so that the front and back of the N-type monocrystalline silicon wafer form a textured layer;

[0081] S2: P diffusion: double-sided or single-sided P diffusion of N-type single crystal silicon wafers with phosphorus source to form FSF on the front side of N-type single crystal silicon wafers;

[0082] S3: Edge isolation: Use a mixed solution of HF and HN03 to remove the back and edge junctions of the N-type single crystal silicon wafer, and only keep the front diffusion layer and the PSG layer above the diffusion layer as the next step of single-side polishing mask;

[0083] S4: Single-side polishing: polishing the back of the N-type monocrystalline silicon wafer with NaOH wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com