Cutting-tool operation reliability evaluation method based on SVD transformation and support vector space

A support vector, reliability technology, used in character and pattern recognition, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

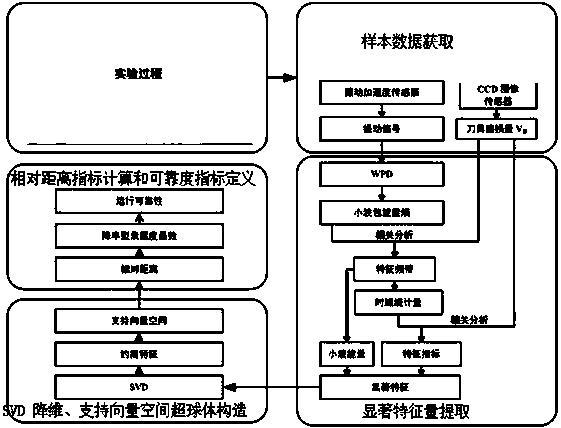

[0071] For CNC lathe processing tools, the failure definition and life estimation in ISO3685, ISO8688, GB / T16461 are based on a certain point value in the wear area. The most commonly used index is the wear amount Vm of the flank. These data are It needs to be acquired through an industrial microscope or a CCD camera. There are disadvantages such as high price, intermittent measurement, stoppage interference processing, etc., and it is difficult to perform real-time dynamic evaluation of its operating status. This patent uses vibration signals as the research object to characterize the wear process of the tool, that is, the vibration signals are processed to obtain fault characteristics and complete failure. evaluation process.

[0072] Experimental process: The machine tool model used in this experiment is Taiwan Youjia Seiki FTC-20 CNC lathe, and the tool model used in the experiment is CNMG120408-HM. In the experiment, the MZDH0670 series video microscope system was used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com