High frequency USB 3.2 wire rod and manufacture method thereof

A USB3.2 and manufacturing method technology, applied in the field of USB wires, can solve the problems of poor transmission frequency and transmission efficiency, insufficient transmission speed, limited technical level, etc., achieve the effect of protective insulation transmission, high transmission efficiency, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

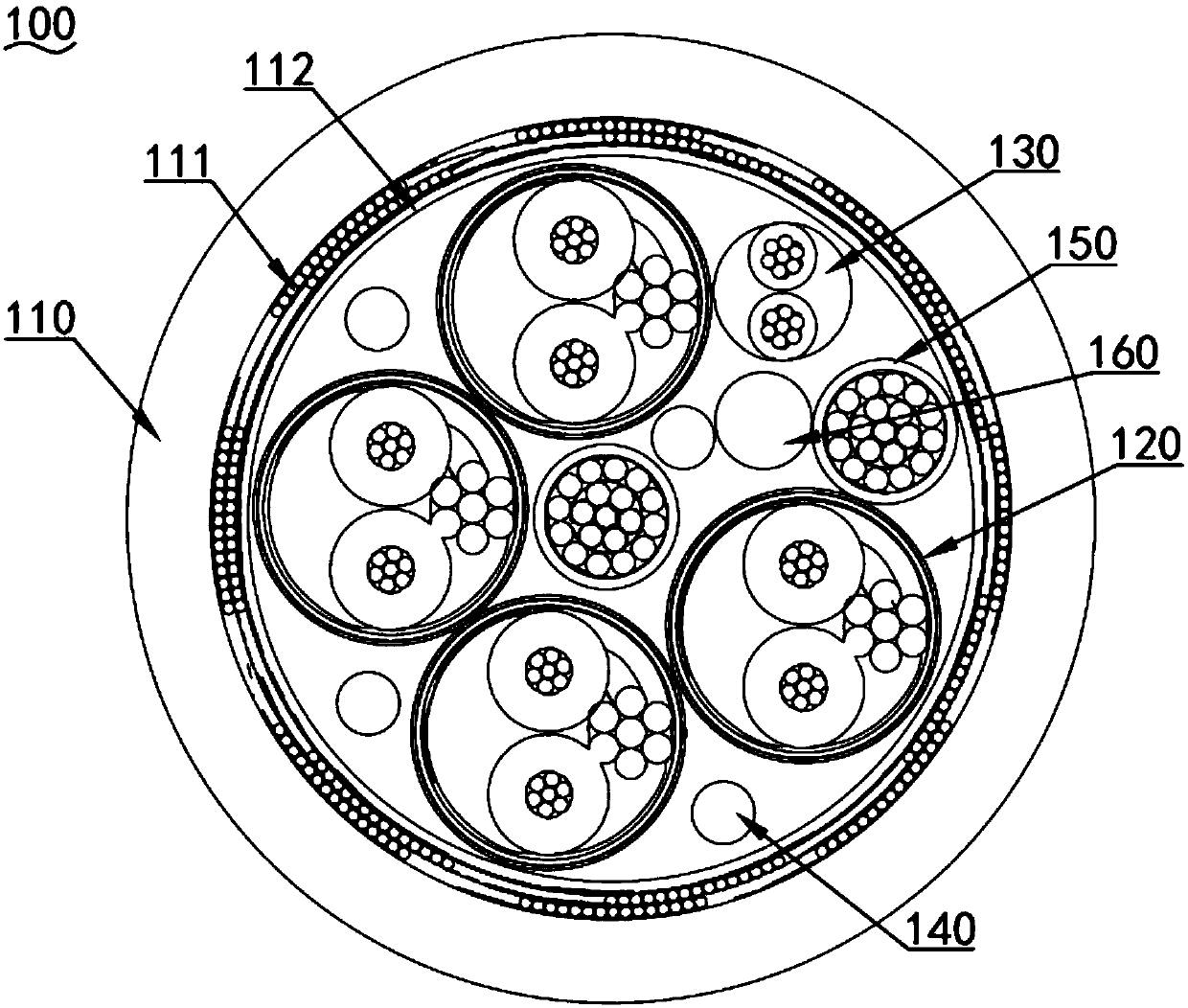

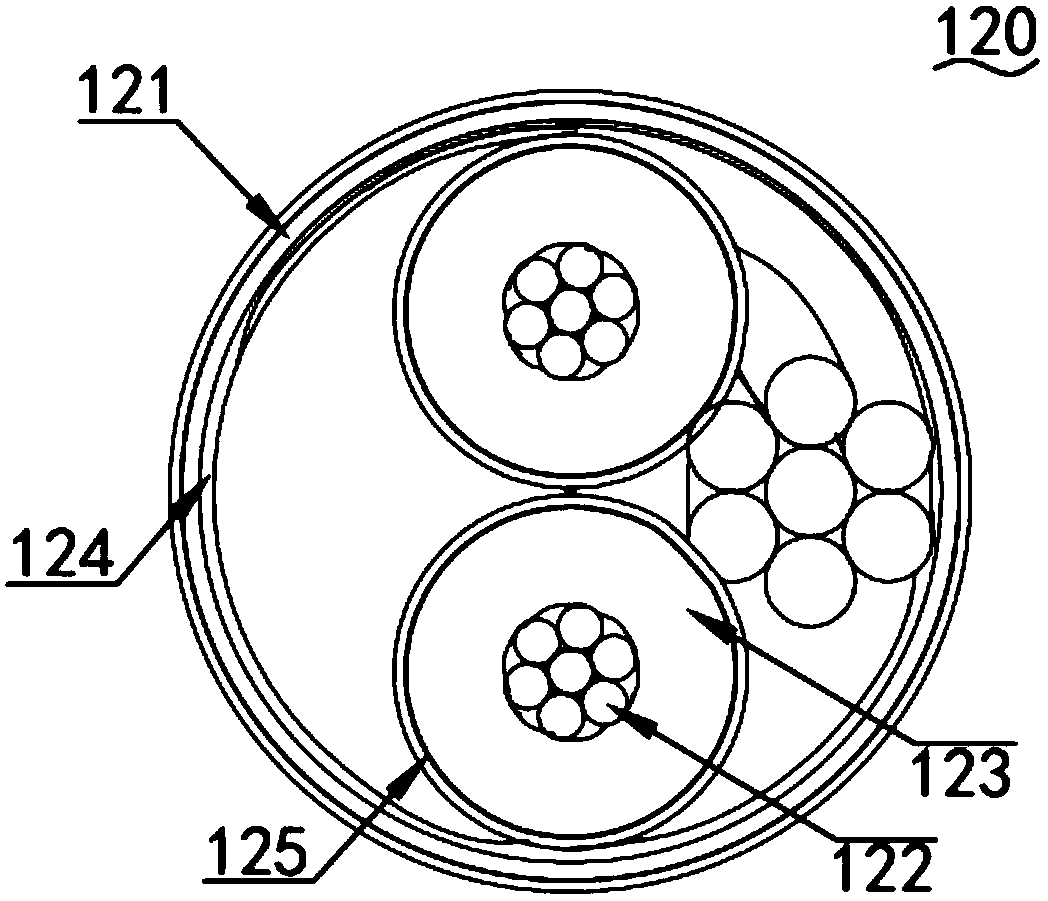

[0052] Such as Figure 1 ~ Figure 2 Shown are the schematic diagram of the structure of the present invention and the schematic diagram of the structure of the high-frequency twisted wire.

[0053] A high-frequency USB3.2 wire 100, including an outer jacket 110, the inner layer of the outer jacket 110 is sequentially provided with a braid 111 and an insulating film 112; Stranded wire 130, conductive wire core 140, voltage wire 150 and insulated cotton wire 160. The high-frequency pair twisted wire 120 includes an isolation layer 121, and the isolation layer 121 is covered with several strands of high-frequency wire core 122, at least one of which is high The frequency core 122 is coated with a rubber coating layer 123; the inner diameter of the isolation layer 121 is provided with a first copper foil layer 124 to cover several strands of the high frequency core 122, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com