Cooling water circulation system of nano grinding equipment

A technology of equipment cooling water and circulation system, applied in grain processing and other directions, can solve the problems of setting cooling channels and not being able to effectively achieve cooling, etc., and achieve the effects of efficient circulating cooling, improving grinding efficiency, and increasing rotation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

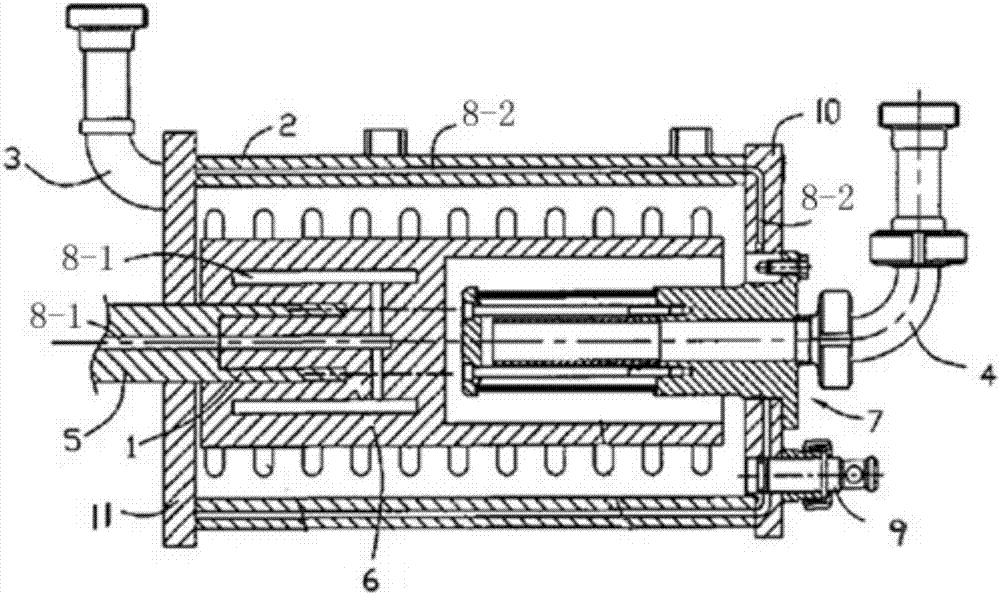

[0023] The nano-grinding equipment cooling water circulation system of the present invention is applied on the pin-type nano-grinding equipment, such as figure 1 As shown, the cooling water circulation system includes a frame 1, a grinding cylinder 2, a feed port 3 and a discharge port 4, the feed port is connected to the grinding cylinder through a feed pipe, and the discharge port is connected to the grinding cylinder through a discharge pipe; The frame is provided with a left end cover 11 and a right end cover 10. A rotating shaft is passed through the left end cover, and the rotating shaft extends into the grinding cylinder, and a rotor 6 is fixedly arranged on the rotating shaft; a rotating shaft is provided on the grinding cylinder. A separator 7, which communicates with the discharge pipe.

[0024] A first cooling channel 8 - 1 communicating with each other is provided between the rotating shaft 5 and the rotor 6 ; a second cooling channel 8 - 2 communicating with each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com