Automatic loading and unloading device for precision part of automatic lathe

A technology of automatic loading and unloading, precision parts, applied in metal processing equipment and other directions, can solve the problems of low feeding efficiency, high labor cost, difficult to ensure the consistency of product direction, etc., to achieve the effect of easy control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

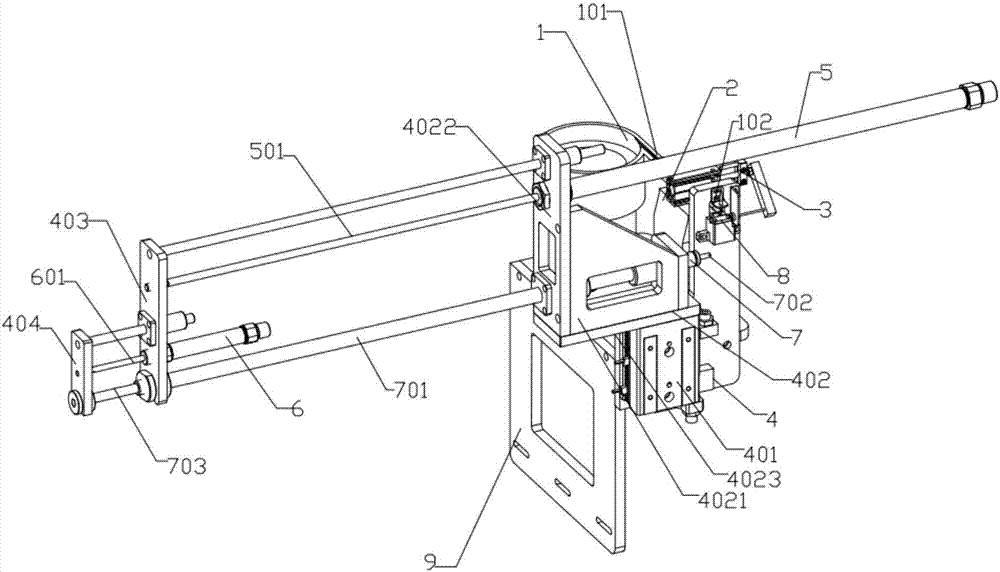

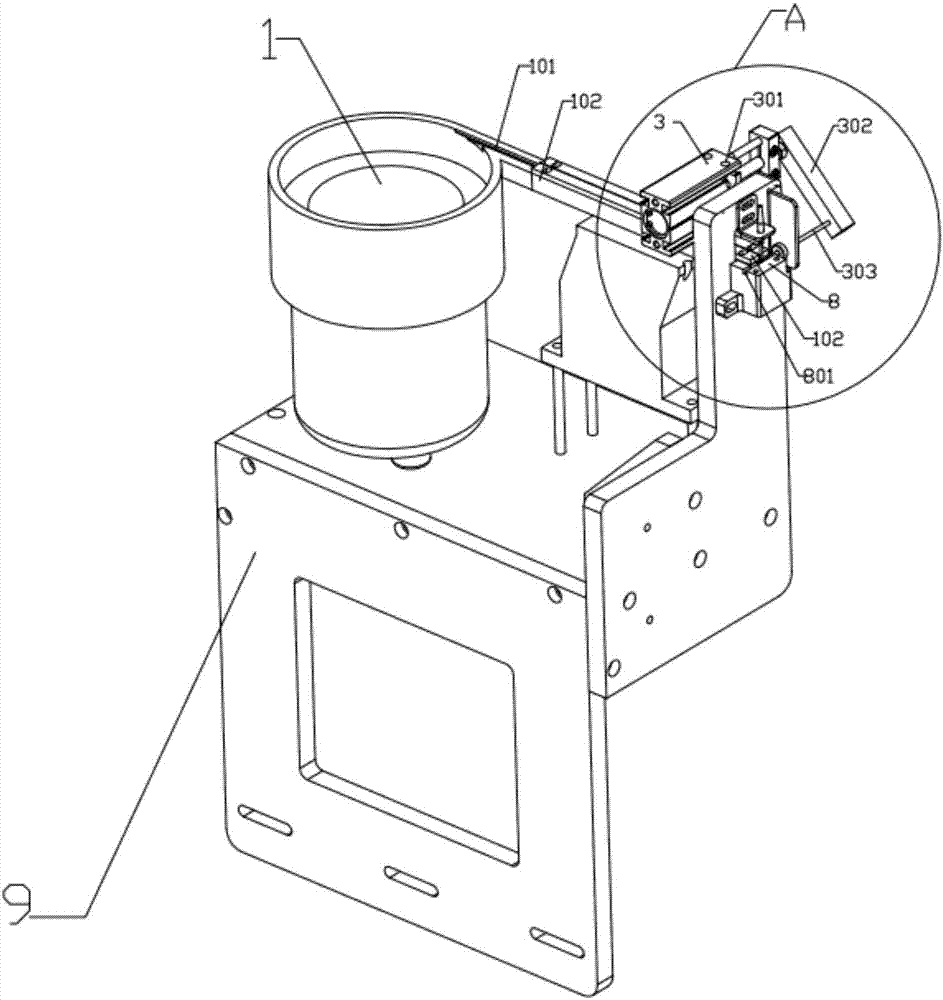

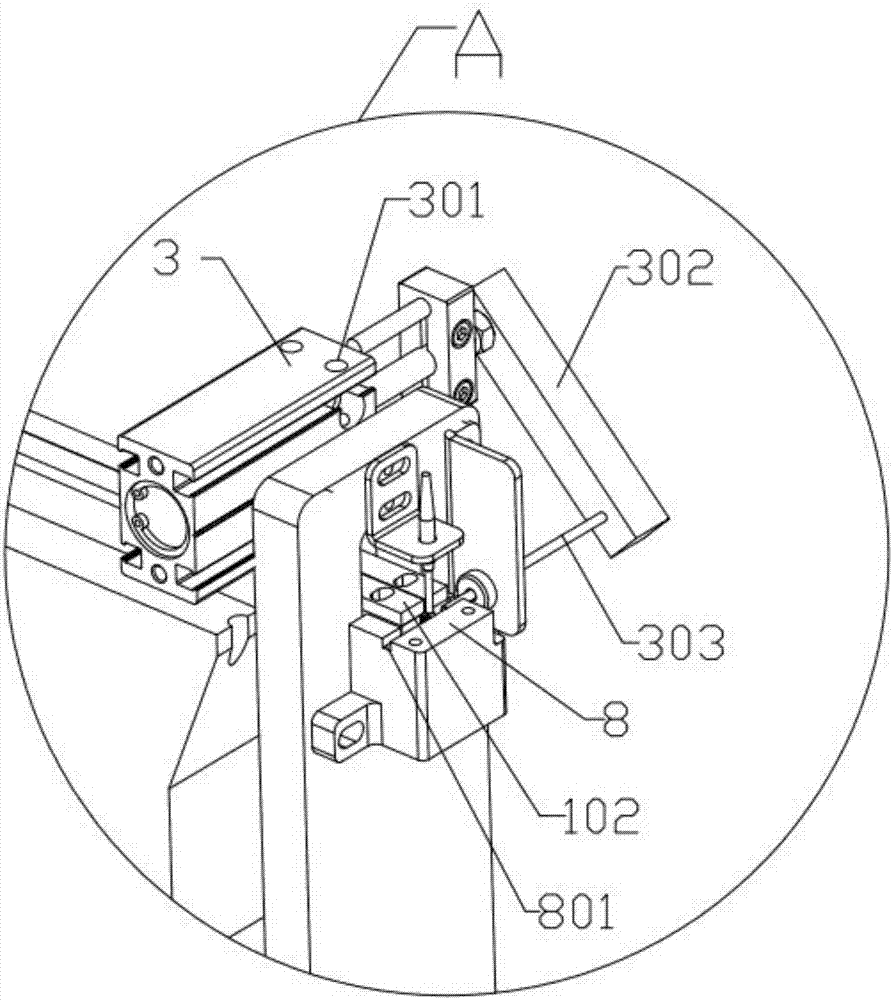

[0019] Attached below Figures 1 to 4 The present invention is described in further detail.

[0020] refer to Figure 1 to Figure 4 , an automatic loading and unloading device for precision parts of an automatic lathe, comprising a vibrating plate 1, the vibrating plate 1 is provided with a material channel 101, the vibrating plate 1 is used to place material products, and the material products can fall into the material channel 101 from the vibrating plate 1; 8. The distribution tray 8 is set on the side of the discharge port of the material channel 101. The material distribution tray 8 is used to place the material products conveyed from the material channel 101. The pushing device 3 is located on the material distribution tray 8 One side of the pusher device 3 can push the material product in the material distribution tray 8 to move; the upper and lower loading device 4, the upper and lower charging device 4 is arranged on one side of the pusher device 3, and the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com