Automatic soldering iron device

An automatic welding and soldering iron technology, applied in the direction of soldering irons, welding equipment, metal processing equipment, etc., can solve the problems of inability to realize welding and cutting, inability to realize fast welding, and high uncertainty coefficient, so as to improve welding efficiency, improve welding quality, The effect of convenient welding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

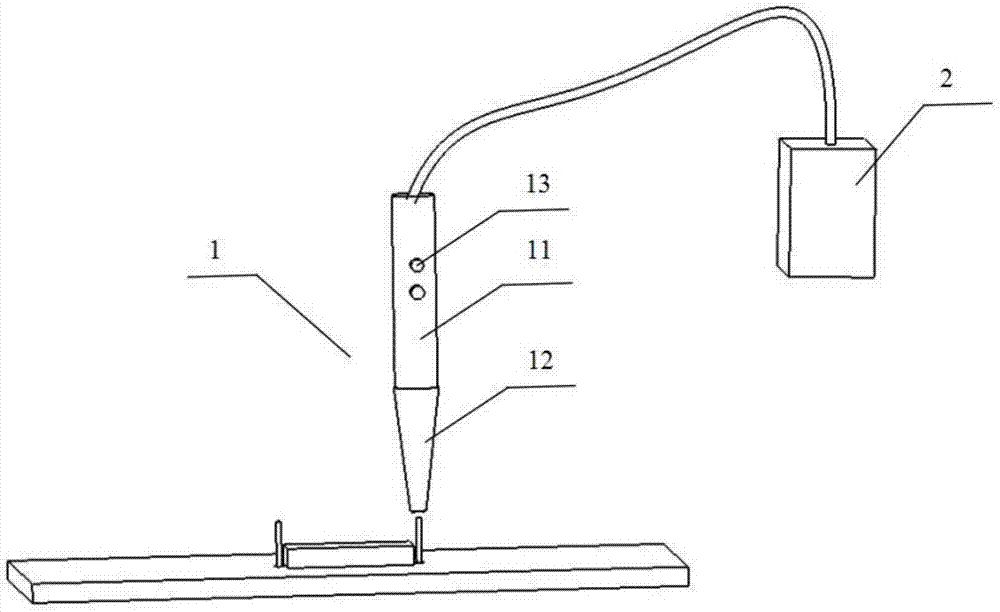

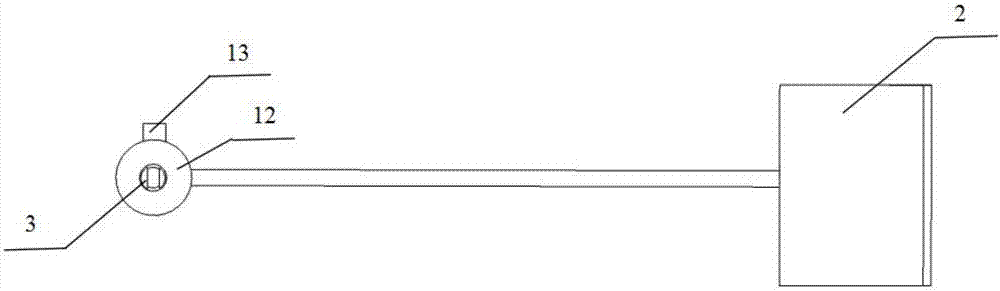

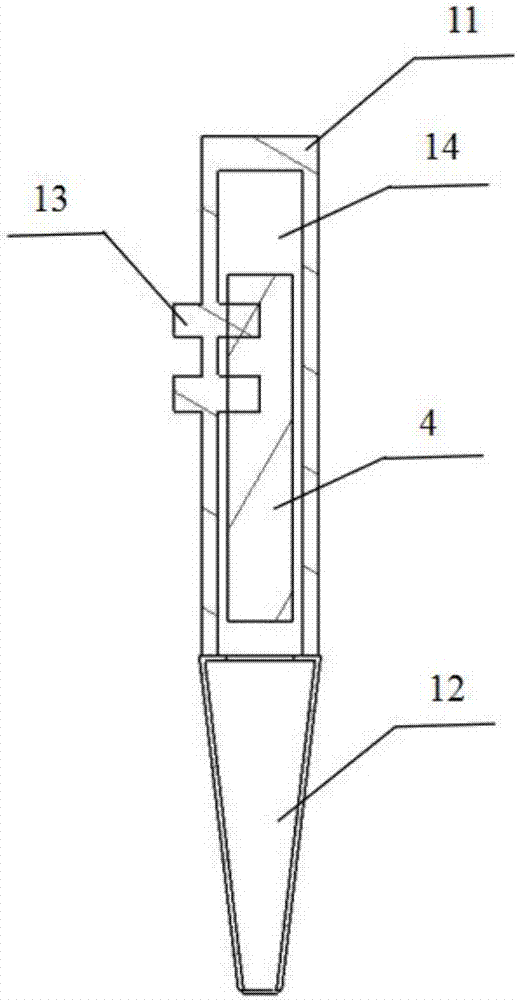

[0024] like figure 1 , 2 As shown in and 3, an automatic soldering iron device 1 includes an external power supply device 2, a hand-held part 11, and a welding head 12 connected to the lower end of the hand-held part 11. The welding end of the welding head 12 is provided with a The heating device of the material, the heating device is a ring-shaped heating wire, the middle of the hand-held part 11 is a cavity structure 14, and also includes a solder block 4 arranged inside the cavity structure 14, and arranged in the cavity structure 14. The cutting device 3 at the bottom of the welding end of the welding head 12 also includes a pushing device arranged inside the cavity structure 14, and also includes a control device 13 arranged on the handle 11, and the control device 13 is connected to the The heating device, the cutting device 3 and the pushing device are all electrically connected. like figure 2 As shown, the cutting device 3 is two blades symmetrically arranged in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com