A kind of welding method of gripper shell

A welding method and shell technology, which is applied in the field of projectile shell welding, can solve the problems of high scrap rate, difficulty in controlling the shape of the inner hole, consistent shape of ferrules, etc., achieve low welding process requirements, and reduce welding technical requirements , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

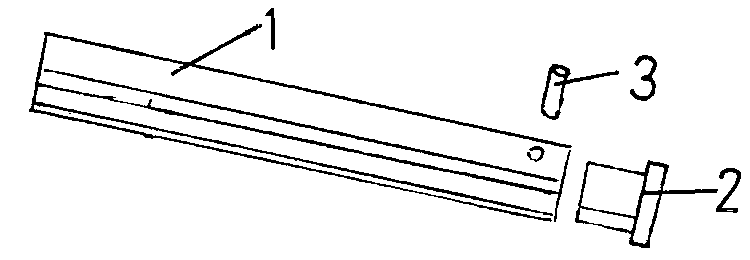

[0022] A welding method for a gripper case, the gripper case includes a shuttle body 1 and a shuttle head 2; the shuttle head has a stepped structure, the small end of the stepped structure is inserted into the shuttle body, and the large end of the stepped structure The inner end surface is in contact with the end surface of the shuttle body, and the small end is provided with a pin hole; the shuttle body is provided with a pin hole matching with the pin hole on the shuttle head; the pin 3 is inserted in the pin hole to connect the shuttle head and the shuttle body Integrate; the shuttle body and the shuttle head are also connected by high-frequency pressure welding; including the following steps:

[0023] (1) Clean up the welding contact surface and add solder pieces on the welding contact surface;

[0024] (2) Assemble the shuttle body, shuttle head and pin into one;

[0025] (3) The shuttle body and the shuttle head are welded by high-frequency welding method;

[0026] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com