Easy-welding high-strength large-thickness steel plate preheating-free gas shielded welding process

A technology of gas shielded welding and high-strength steel plates, applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effects of low welding technical requirements for workers, improved welding production efficiency, and improved overall reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method in embodiment 1 is as follows:

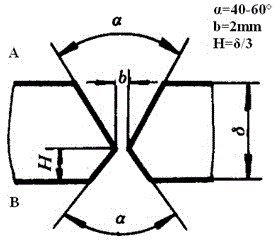

[0035] The processing size of the steel plate sample is 80mm (thickness) × 200mm × 600mm, 2 pieces are 1 group, and according to the attached figure 1 It is required to process the groove, check the size of the processed steel plate, assemble it strictly according to the assembly requirements after the size is qualified, weld enough fixing devices to ensure the assembly accuracy and prevent the deformation of the steel plate, and spot weld the arc strike plate with a length of 120mm.

[0036] The specific welding steps are as follows:

[0037] (1) Welding base metal: The thickness of the large-thickness high-strength steel plate used is 80mm, and its main chemical composition weight percentage is: C: 0.05-0.12%, Si: 0.20-0.40%, Mn: 1.55-1.65%, P≤ 0.012%, S≤0.005%, Als: 0.020~0.040%, Ti: 0.015~0.030%, Mo: 0.010~0.025%, Cr≤: 0.020~0.030%, B: 0.0005~0.0020%, the rest is Fe and unavoidable impurities; the chemical co...

Embodiment 2

[0053] The difference between embodiment 2 and embodiment 1 is that in embodiment 2, the welding heat input is different, and embodiment 2 adopts THQ-70C welding wire with a diameter of Φ1.6mm, and the welding heat input control target is 35kJ / cm ;

[0054] Example 2 During welding, after each layer of welding, lightly tap along the weld seam with a hand hammer to release part of the welding stress and reduce deformation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com