Brazing method, heat exchanger structure, plate heat exchanger and air conditioner

A plate heat exchanger and heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve problems such as product failure and affect product appearance, improve quality, avoid help The effect of flux residue and leakage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

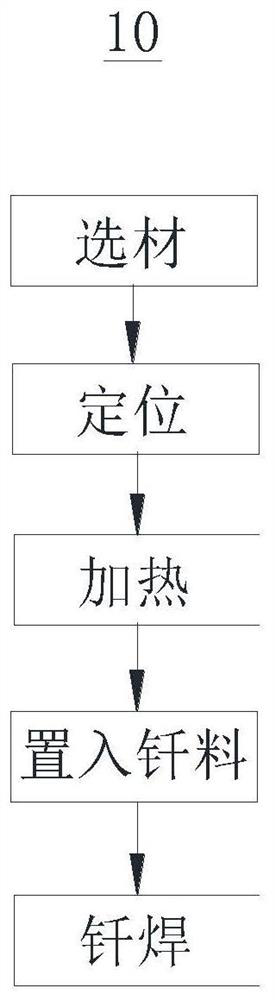

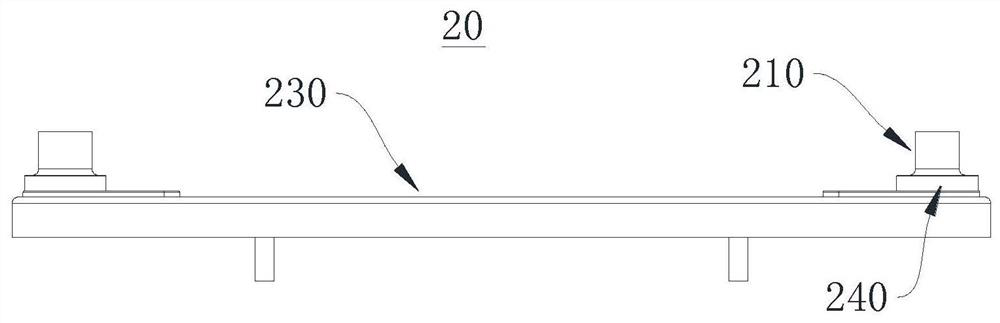

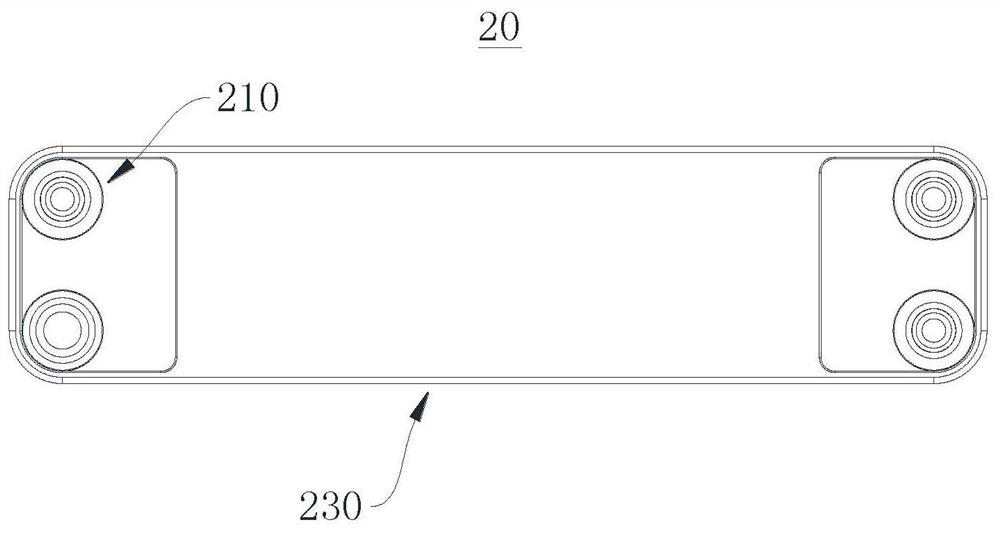

[0036] Please refer to Figures 1 to 4 , the brazing method 10 provided by the present invention includes the step of directly welding the first piece to be welded and the second piece to be welded through solder, wherein the first piece to be welded and the second piece to be welded are used to form The parts in the welding area are all made of copper material, and the melting point of the solder is lower than the melting point of the first piece to be welded and the melting point of the second piece to be welded. In the brazing process, since the parts constituting the welding area on the first piece to be welded and the second piece to be welded are made of copper material, the first piece to be welded and the second piece to be welded can be directly welded by solder without Solid or liquid flux is used to avoid the phenomenon of flux residues, which can effectively pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com