H-shaped arm for pneumatic suspension

An air suspension and wishbone technology, which is applied to suspensions, elastic suspensions, cantilevers mounted on pivots, etc., can solve the problems of inconvenient installation and inconvenient processing, achieve convenient processing, reduce configuration parts, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

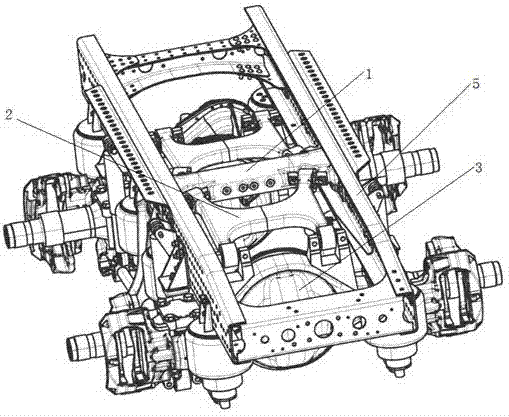

[0025] Such as Figure 1-Figure 6 Shown is an H-shaped arm for an air suspension, which includes a pair of symmetrically arranged longitudinal beams 5, a crossbeam 1 is installed between the two longitudinal beams 5, and an axle is installed at the lower end of the longitudinal beams 5. 3. Both ends of the H-shaped arm 2 are respectively fixed to the axle 3 and the beam 1, including

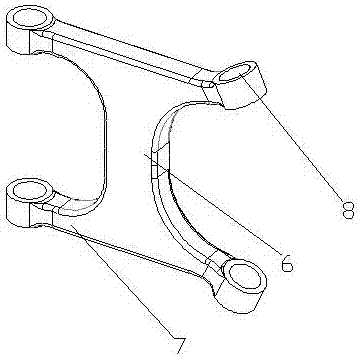

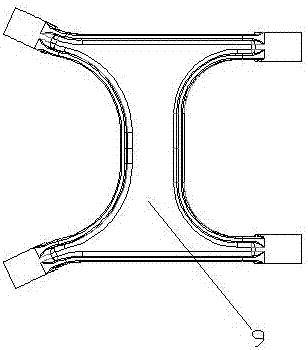

[0026] One H-shaped arm main body, the H-shaped arm main body is H-shaped, has a mounting hole 8 at the four corners of the H-shaped arm main body, and has an H-shaped mounting hole 8 on the upper end of the axle 3 and the side end of the crossbeam 1 respectively. The four end corners of the arm body correspond to the mounts.

[0027] The main body of the H-shaped arm is integrally formed by...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap