Full-automatic food air-drying device

An air-drying device and fully automatic technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of packaging bags that cannot stand upright, inconvenient storage, and low efficiency, so as to avoid the sacrifice of product taste and improve the effect of cleaning. Scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

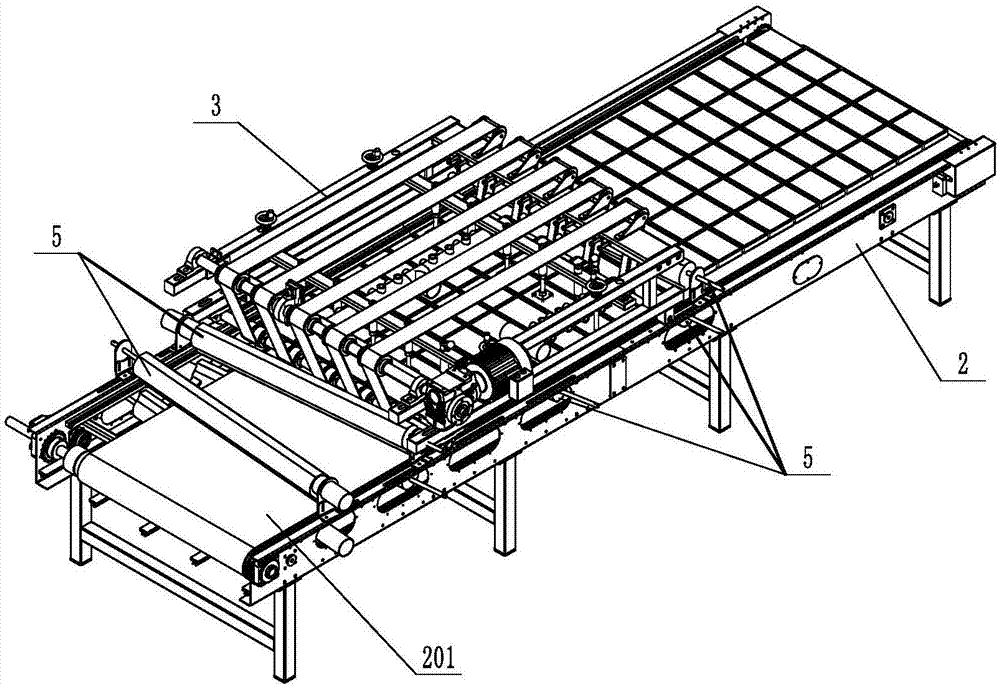

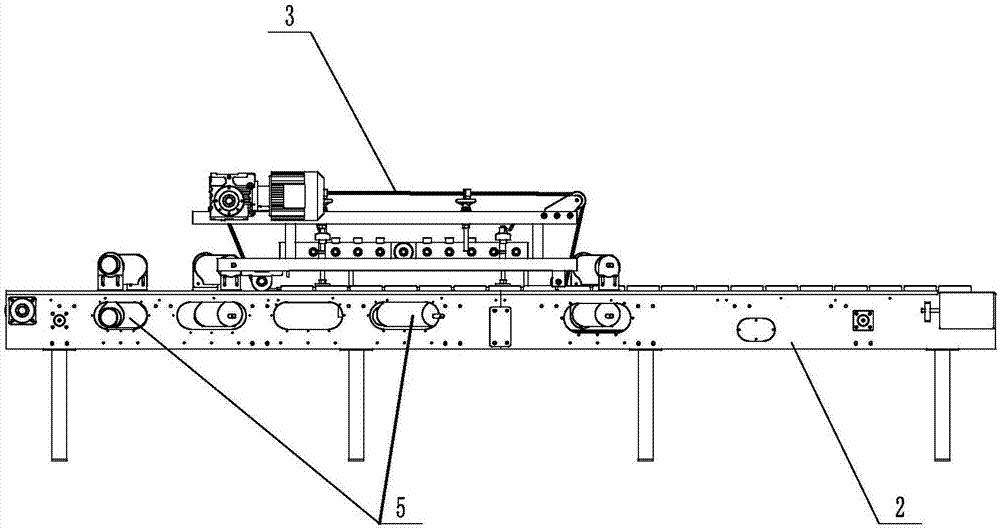

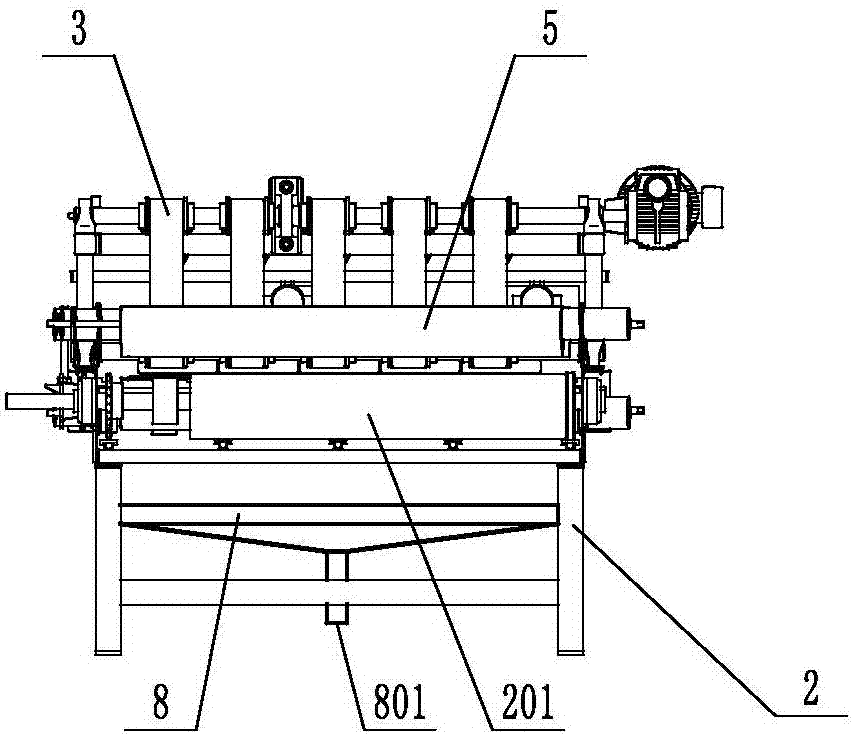

[0037] The entire automatic air-drying line mainly includes the whole tray grabbing of packaging bags, intermittent placement, conveying, first-stage air-drying, second-stage air-drying, third-stage air-drying, and over-transportation.

[0038] In the present invention, the grabbing and placing of the packaging bag is completed by the manipulator 1, wherein the manipulator 1 includes an integrated suction cup combined with a suction cup I 101 and a suction cup II 102, and the suction cup sucks the packaging bag in the material basket 10 as a whole at one time Lift it up, then intermittently release it twice onto the conveying mesh belt 201 made of stainless steel wire, perform preliminary air-drying under the action of the upper and lower air knives 5, and then the packaging bag is conveyed to the pressure bag under the conveying of the mesh belt 201 Institution 3, the second stage of air-drying is carried out.

[0039]As shown in the figure, the pressure bag mechanism 3 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com