Sleeve grouting material for steel bar connection and preparation method thereof

A sleeve grouting and steel bar technology, which is applied in the field of construction engineering, can solve the problems of substandard vertical expansion rate, uneven quality, poor volume stability, etc., and achieve the effects of long working time, easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

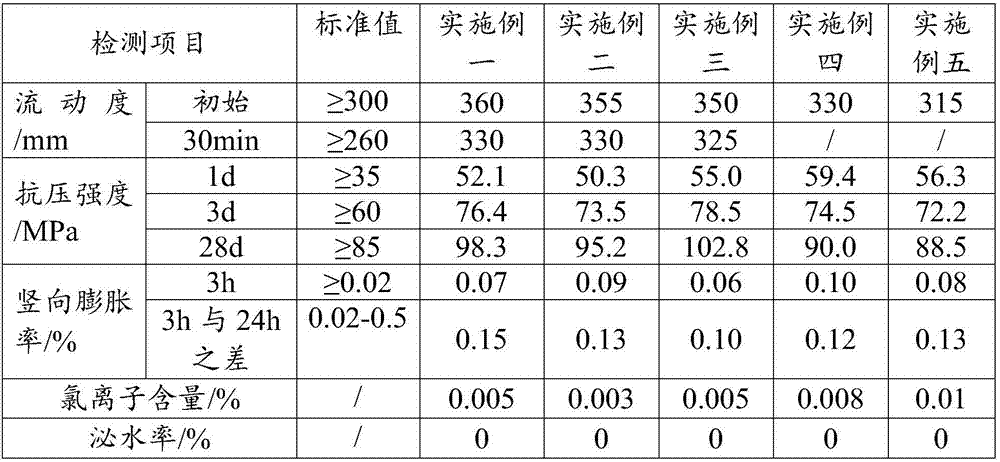

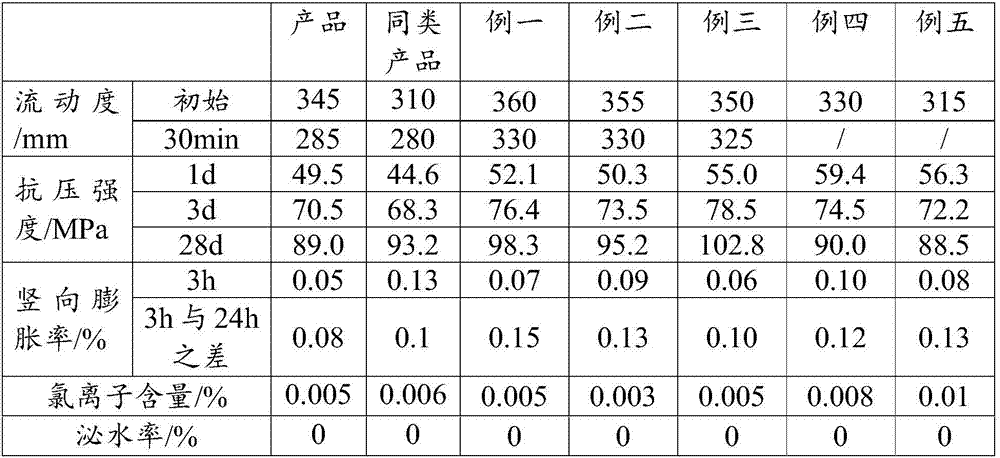

Examples

Embodiment approach 1

[0036] This embodiment provides a sleeve grouting material suitable for use at normal temperature (≥5°C) for non-shrinkage steel bar connections. The grouting material has high fluidity after leaving the machine and 30 minutes, micro-expansion, early strength and high strength, and is easy to produce and construct. , Long working hours, strong environmental adaptability.

[0037] In this embodiment, the cement is mainly composed of 5-100% by weight of ordinary Portland cement and 5-15% by weight of sulphoaluminate cement, and the cement strength grade is not lower than 42.5. Ordinary Portland cement with a cement strength grade of 42.5 is used to compound an appropriate amount of cement strength grade 42.5 sulfoaluminate cement, which can not only ensure the 1d and 3d strength of the grouting material at a low water-cement ratio, but also ensure the continuous growth of the later strength, and The quality of P.O42.5 cement is stable and easy to get.

[0038] Typical but non-l...

Embodiment approach 2

[0057] This embodiment provides a sleeve grouting material for non-shrinkage steel bar connection used at low negative temperature (-10°C-5°C). The grouting material has high fluidity, micro-expansion, early strength and high strength, and is easy to produce and construct. Etc.

[0058] In this embodiment, the cement is mainly composed of 5-10% by weight of ordinary Portland cement and 5-100% by weight of sulphoaluminate cement, and the cement strength grade is not lower than 42.5.

[0059] In this embodiment, the weight percentage of the modifier is 0.05-0.3%, specifically, the typical but non-limiting weight percentages of the modifier are 0.05%, 0.06%, 0.07%, 0.08%, 0.09%, 0.1%, 0.11% %, 0.12%, 0.13%, 0.14%, 0.15%, 0.16%, 0.17%, 0.18%, 0.19%, 0.2%, 0.22%, 0.24%, 0.26%, 0.28%, or 0.3%. In terms of weight percentage, the regulator includes: polyether modified silicon defoamer 0.02-0.05%, retarder 0.03-0.1%, coagulation accelerator 0-0.04%, early strength agent 0.05-0.2%, vis...

Embodiment 1

[0077] The invention provides a sleeve grouting material suitable for use under normal temperature conditions, which comprises the following components in weight percent: 45% cement, 42% aggregate, 8% admixture, and 0.3% polycarboxylate superplasticizer %, plastic expansion agent 0.05%, compound expansion agent 4.58%, regulator 0.07%. The water-to-material ratio can be 0.14 in the preparation process of the sleeve grouting material for steel bar connection.

[0078] Among them, the cement is composed of 92% of ordinary Portland cement with a strength grade of 42.5 and 8% of sulphoaluminate cement with a strength grade of 42.5 by weight percentage.

[0079] The aggregate is washed, dried and screened river sand, which is compounded by weight percentage of 58% of 20-40 mesh and 42% of 40-70 mesh.

[0080] The regulator is composed of 60% defoamer, 15% retarder and 25% viscosity regulator by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com