A high-toughness titanium silicon carbide-silicon carbide composite ceramic special-shaped part

A technology of composite ceramics and titanium silicon carbide, which is applied in the field of ceramic materials, can solve the problems of difficulty in the preparation of silicon carbide products with complex shapes, high sintering temperature, and high processing difficulty, so as to prevent brittle fracture, shorten the production process, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

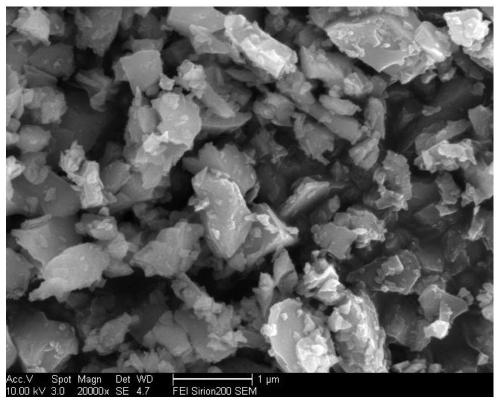

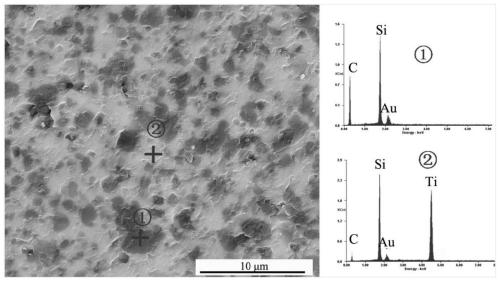

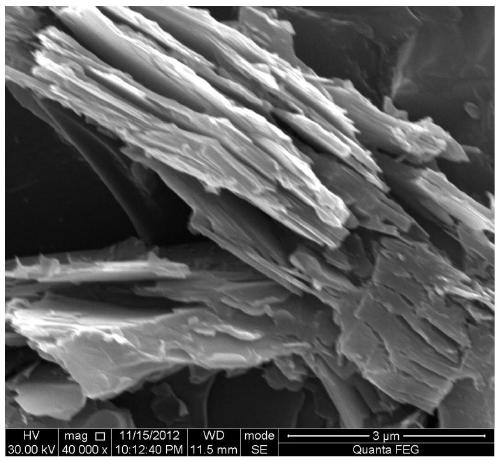

[0036] 1) disperse 110g carbon black, 55g titanium carbide powder (average particle diameter 2 microns), 22g titanium powder (average particle diameter 3 microns) and 4g polyvinyl alcohol, 6g sodium carboxymethyl cellulose in deionized water, then Ball milling for 24h to obtain ceramic slurry;

[0037] 2) Move the ceramic slurry into a vacuum container, vacuumize and degas under 10Pa, then slowly inject the slurry into a plaster mold, and dry for 3 days after demoulding to obtain a special-shaped green body;

[0038] 3) Move the special-shaped blank into the vacuum sintering furnace, evenly spread a certain amount of high-purity silicon powder on the top of the blank (the amount of silicon is 1.3 times the amount of silicon required for the silicon-carbon chemical reaction), and then carry out infiltration-reaction sintering , the sintering temperature is 1680°C, the holding time is 1.5 hours (the furnace is evacuated to 15Pa when the temperature is lower than 800°C during the...

Embodiment 2

[0040] 1) 100g carbon black, 60g titanium carbide powder (average particle diameter 2 microns), 24g titanium powder (average particle diameter 4 microns) and 6g polyvinyl alcohol, 10g sodium carboxymethyl cellulose are uniformly dispersed in deionized water, then Ball milling for 24h to obtain ceramic slurry;

[0041] 2) Move the ceramic slurry into a vacuum container, vacuumize and degas under 10Pa, then slowly inject the slurry into a plaster mold, and dry for 3 days after demoulding to obtain a special-shaped green body;

[0042] 3) Move the special-shaped blank into the vacuum sintering furnace, evenly spread a certain amount of high-purity silicon powder on the top of the blank (the amount of silicon is 1.3 times the amount of silicon required for the silicon-carbon chemical reaction), and then carry out infiltration-reaction sintering , the sintering temperature is 1660°C, and the holding time is 1 hour (the furnace is evacuated to 12Pa when the temperature is lower than...

Embodiment 3

[0044] 1) disperse 120g carbon black, 50g titanium carbide powder (average particle diameter 1 micron), 17g titanium powder (average particle diameter 2 micron) and 5g polyvinyl alcohol, 8g sodium carboxymethyl cellulose in deionized water, then Ball milling for 24h to obtain ceramic slurry;

[0045] 2) Move the ceramic slurry into a vacuum container, vacuumize and degas under 10Pa, then slowly inject the slurry into a plaster mold, and dry for 3 days after demoulding to obtain a special-shaped green body;

[0046] 3) Move the special-shaped blank into the vacuum sintering furnace, evenly spread a certain amount of high-purity silicon powder on the top of the blank (the amount of silicon is 1.3 times the amount of silicon required for the silicon-carbon chemical reaction), and then carry out infiltration-reaction sintering , the sintering temperature is 1690°C, and the holding time is 1 hour (the furnace is evacuated to 18Pa when the temperature is lower than 800°C during the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com