Production method of naphthalene-free cyclopentane

A production method and technology for naphthalenecyclopentane are applied in the field of cyclopentane denaphthalene treatment, can solve problems such as naphthalene poisoning, and achieve the effects of avoiding naphthalene poisoning, safe production and operation, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

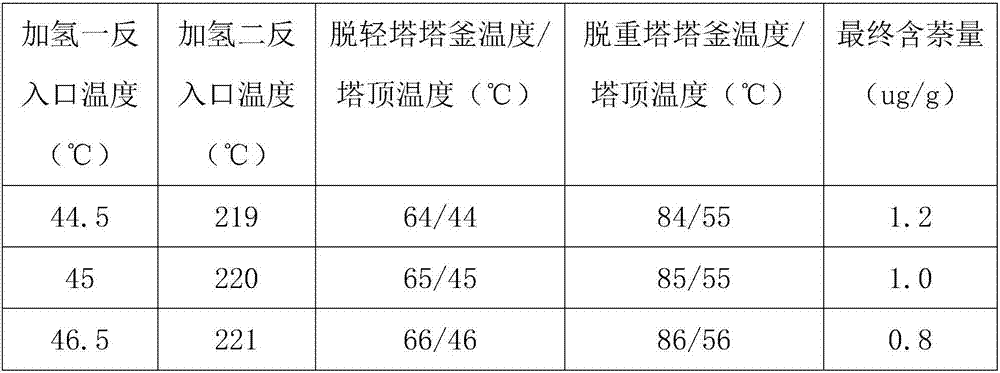

Embodiment 1

[0016] In the embodiment of the present invention 1: a kind of production method without naphthalene cyclopentane, process step is as follows:

[0017] 1) Mixing stage: import cracked carbon five and finished cyclopentane with a mass fraction ratio of 7:3 into the stirred tank, and carry out pressurized stirring. Mix evenly to form a mixed material;

[0018] 2) Hydrogenation stage: the mixed material obtained in step 1) is preheated by a preheater, introduced into a hydrogenation reactor for one-inversion and two-inversion hydrogenation, and the hydrogenation material is exported, filtered, and impurities are removed to obtain a hydrogenation product; The hydrogenation-reverse inlet temperature is 44.5°C, the temperature rise is 60°C, the amount of circulating material is 5 times that of the feed amount, the pressure is 2.2MPa, the hydrogen-oil ratio is 8, and the catalyst is a nickel catalyst. In terms of weight ratio, the nickel catalyst The amount used is nickel catalyst: ...

Embodiment 2

[0020] In the embodiment of the present invention 2: a kind of production method without naphthalene cyclopentane, process step is as follows:

[0021] 1) Mixing stage: import cracked carbon five and finished cyclopentane with a mass fraction ratio of 7:3 into the stirred tank, and carry out pressurized stirring. Mix evenly to form a mixed material;

[0022] 2) Hydrogenation stage: the mixed material obtained in step 1) is preheated by a preheater, introduced into a hydrogenation reactor for one-inversion and two-inversion hydrogenation, and the hydrogenation material is exported, filtered, and impurities are removed to obtain a hydrogenation product; The hydrogenation-reverse inlet temperature is 45°C, the temperature rise is 65°C, the amount of circulating material is 5 times that of the feed amount, the pressure is 2.2MPa, the hydrogen-oil ratio is 8, and the catalyst is a nickel catalyst. In terms of weight ratio, the nickel catalyst The amount used is nickel catalyst: mi...

Embodiment 3

[0024] In the embodiment of the present invention 3: a kind of production method without naphthalene cyclopentane, process step is as follows:

[0025] 1) Mixing stage: import cracked carbon five and finished cyclopentane with a mass fraction ratio of 7:3 into the stirred tank, and carry out pressurized stirring. Mix evenly to form a mixed material;

[0026] 2) Hydrogenation stage: the mixed material obtained in step 1) is preheated by a preheater, introduced into a hydrogenation reactor for one-inversion and two-inversion hydrogenation, and the hydrogenation material is exported, filtered, and impurities are removed to obtain a hydrogenation product; The hydrogenation-reverse inlet temperature is 45.5°C, the temperature rise is 70°C, the amount of circulating material is 5 times that of the feed amount, the pressure is 2.2MPa, the hydrogen-oil ratio is 8, and the catalyst is a nickel catalyst. In terms of weight ratio, the nickel catalyst The amount used is nickel catalyst: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com